Sealing structure of electronic product annealing or sintering furnace and carrying cart

An electronic product and sealing structure technology, which is applied in the field of electronic product annealing or the sealing structure of firing furnace and loading trolley, can solve the problems affecting the quality of electronic products, energy waste, furnace inlet and outlet escape, etc., to ensure annealing or fired mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

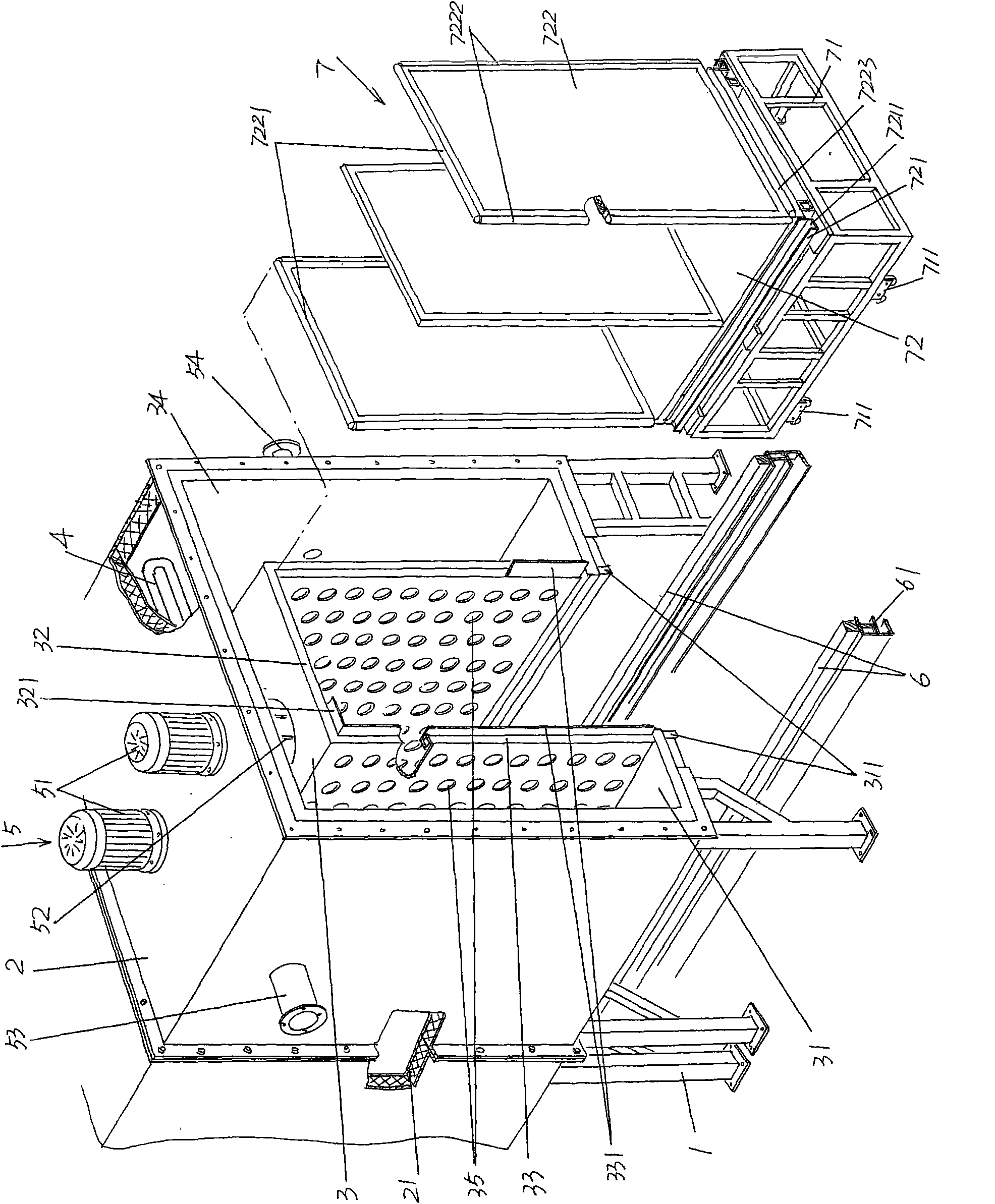

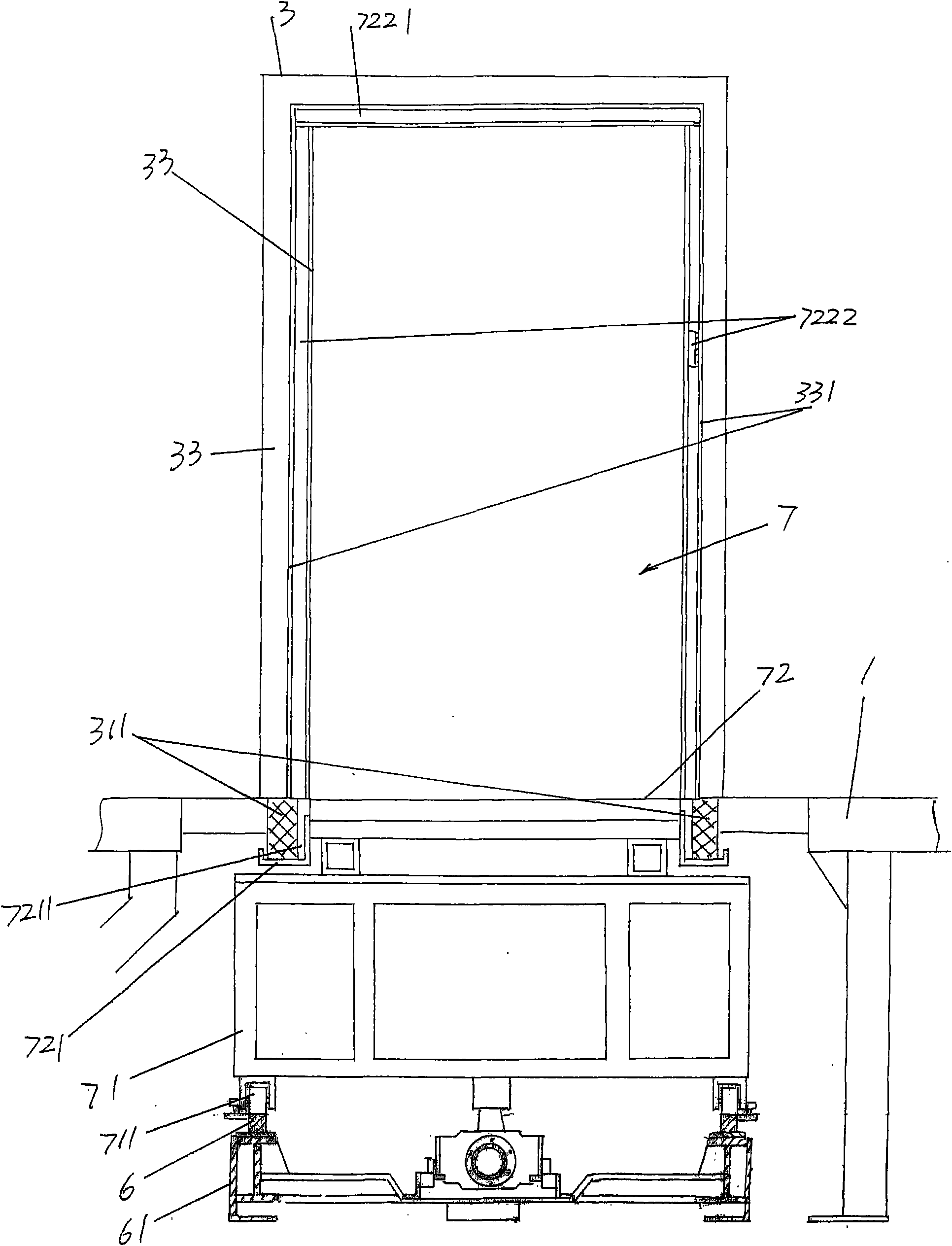

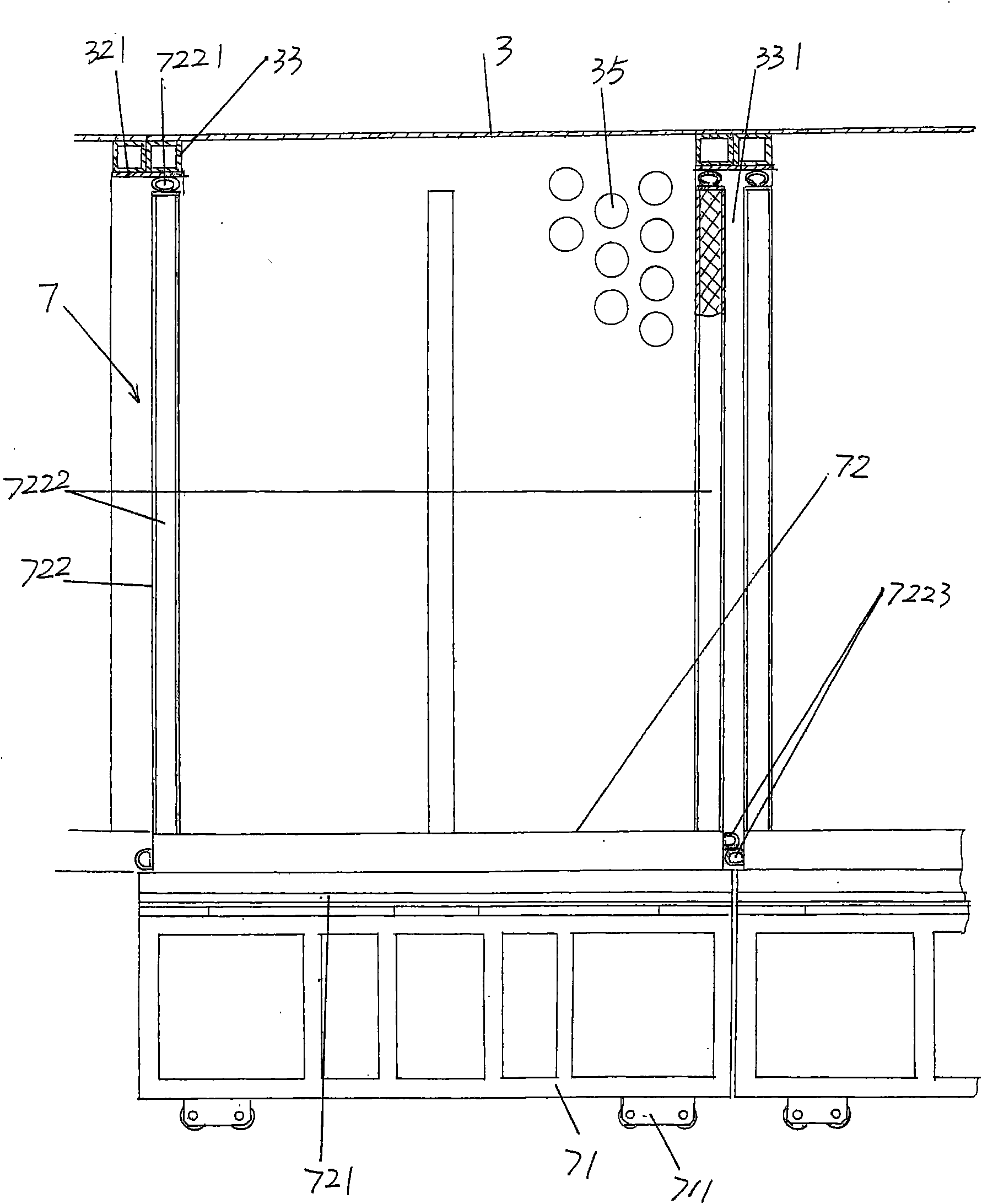

[0024] please see figure 1 , figure 2 and image 3 According to the well-known common sense in the industry, the length of the furnace body 2 as an annealing or firing furnace for electronic products is determined according to needs, the short is several meters or tens of meters, and the length is nearly a hundred meters or more than a hundred meters. Therefore, in this implementation In the example, the length of the furnace body 2 does not need to be limited. The furnace body 2 is fixed on the furnace frame 1 in a spaced state (the furnace frame 1 is a supporting foot), and the top of the furnace body 2 is equipped with a heating device 4 and a hot air circulation device 5, and the heating device 4 is located on the top of the furnace body 2 The inside of the inner side, that is, at the top of the hot air circulation cavity 34 formed between the furnace body 2 and the furnace 3, the hot air circulation device 5 includes a motor 51 whose number is not limited in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com