Heat exchanger

A technology of heat exchangers and sectors, applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of increasing vortex, reducing effect, uneven speed, etc., to reduce maintenance costs and reduce division intervals , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

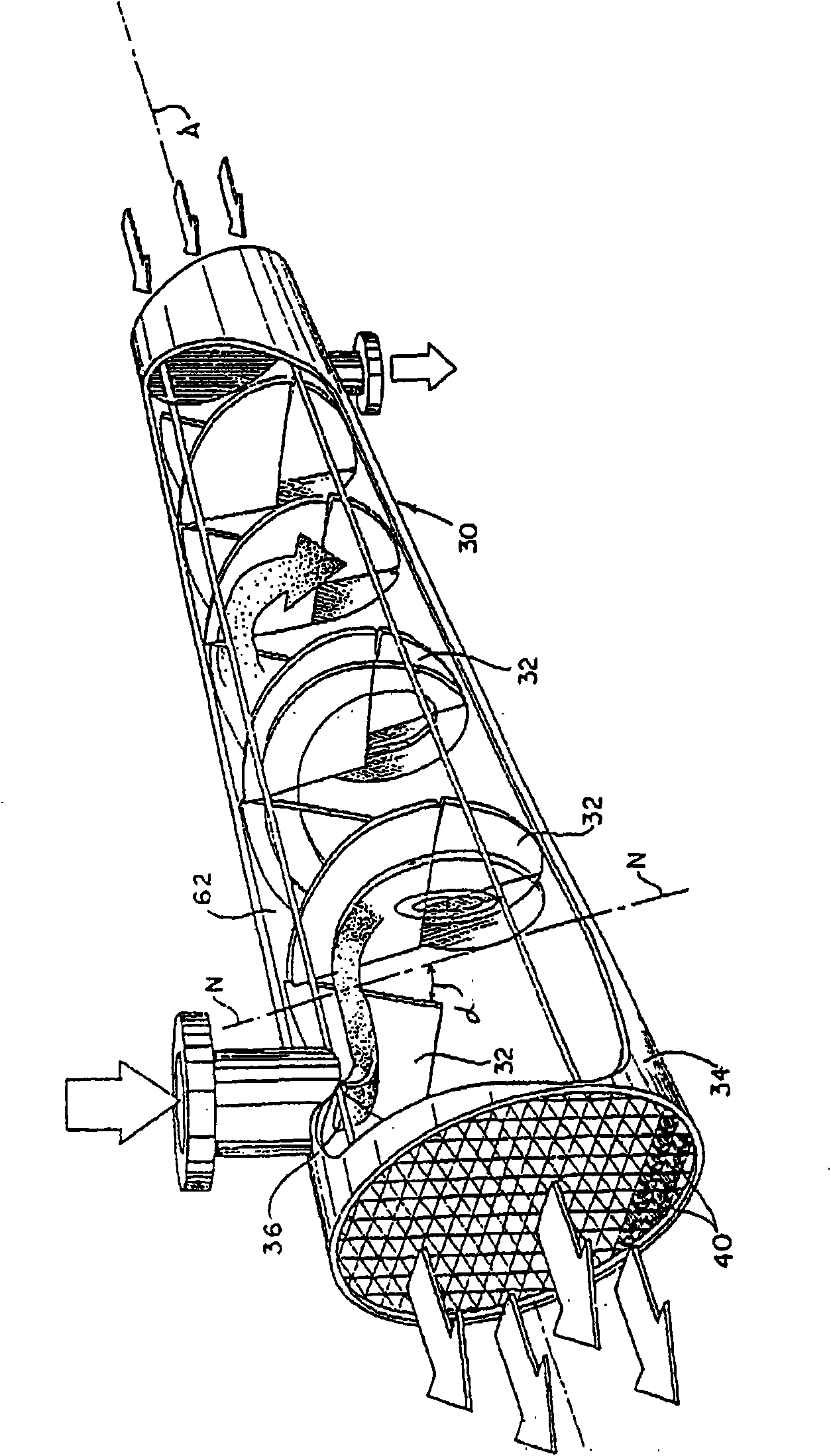

[0046] refer to figure 2 , the spiral baffle heat exchanger 30 of the present invention consists of a plurality of sector baffles 32, each of which is placed at an angle λ with respect to the normal line N-N to the longitudinal axis A-A of the shell 34. Thus, sector baffles 32 (hereafter baffles) direct the cross flow 36 at the sides of the shell in a helical pattern and in a reduced unsupported pipe distance between the baffles. This results in true cross flow on the housing sides with efficient transfer of available pressure drop to heat transfer and reduces damage as vibration of another fluid passing through conduit 40 is minimized. This eliminates dead spots to block cross flow 36 and substantially eliminates the dissipative energy of eddies or backmixing. While the baffles 32 are straight as shown in the figures, opposite sides of each baffle may be curved to direct the cross flow 36 along a helical pattern.

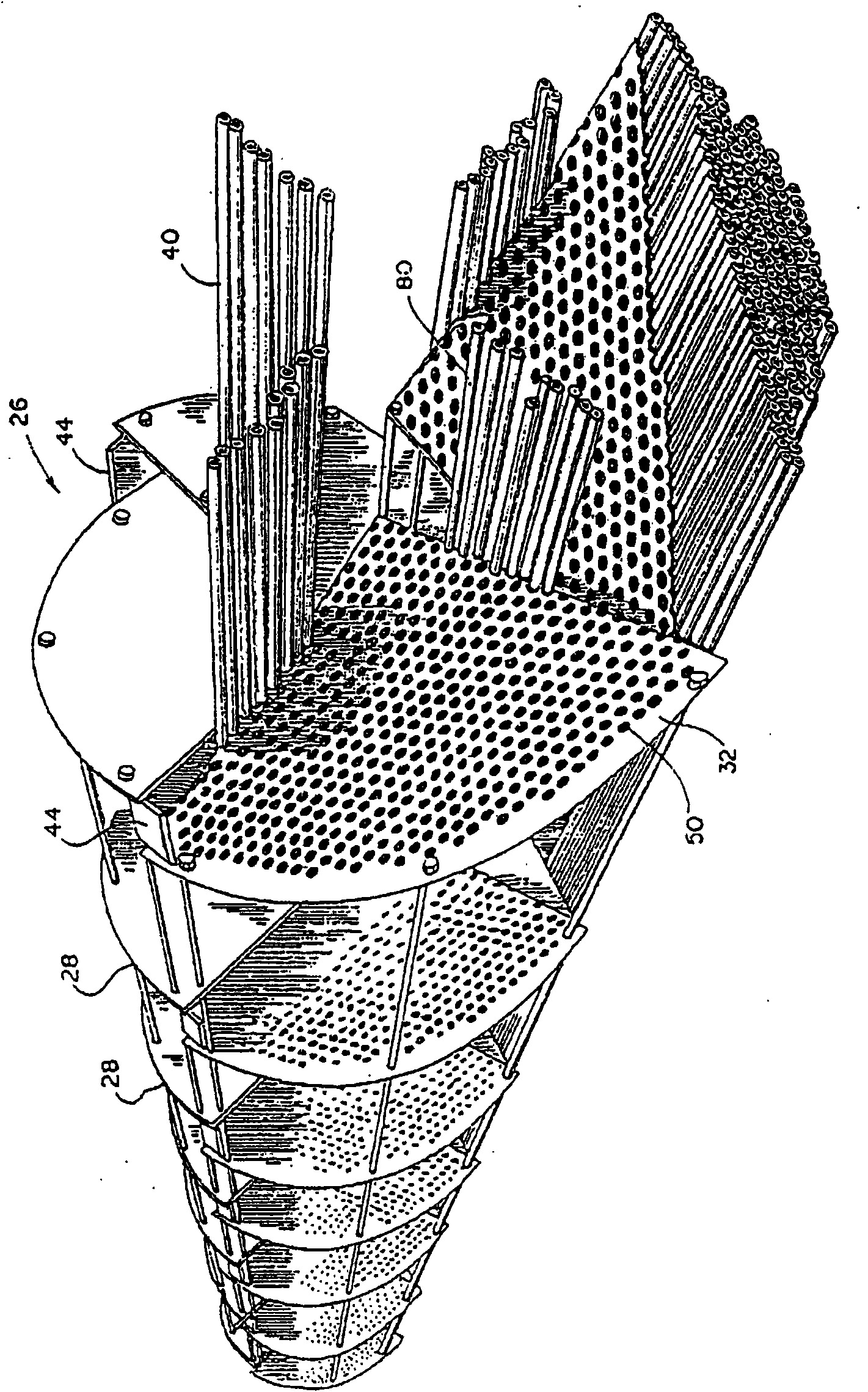

[0047] Such as image 3 and 4 As shown in , the baffle h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com