Device for itinerantly measuring blast furnace charge level

A blast furnace material surface and special-shaped technology, which is applied in the direction of measuring device, lubrication indicator device, liquid/fluid solid measurement, etc., can solve the problem of limited installation position, inability to express the falling speed of blast furnace material surface shape well, and reduced accuracy of measurement results And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

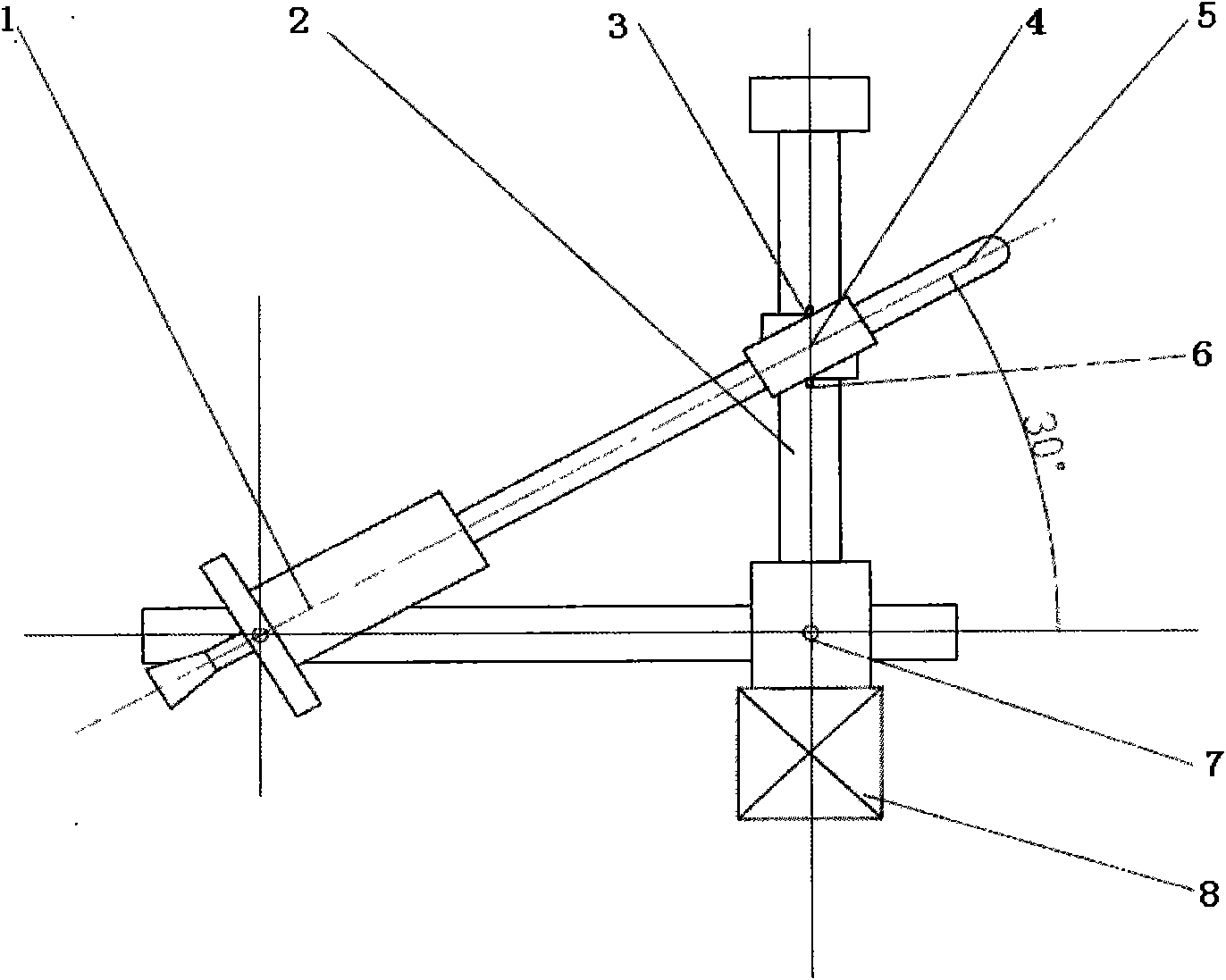

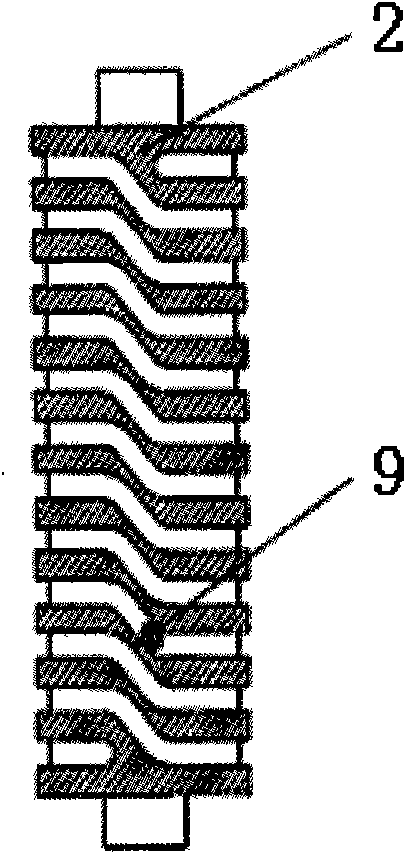

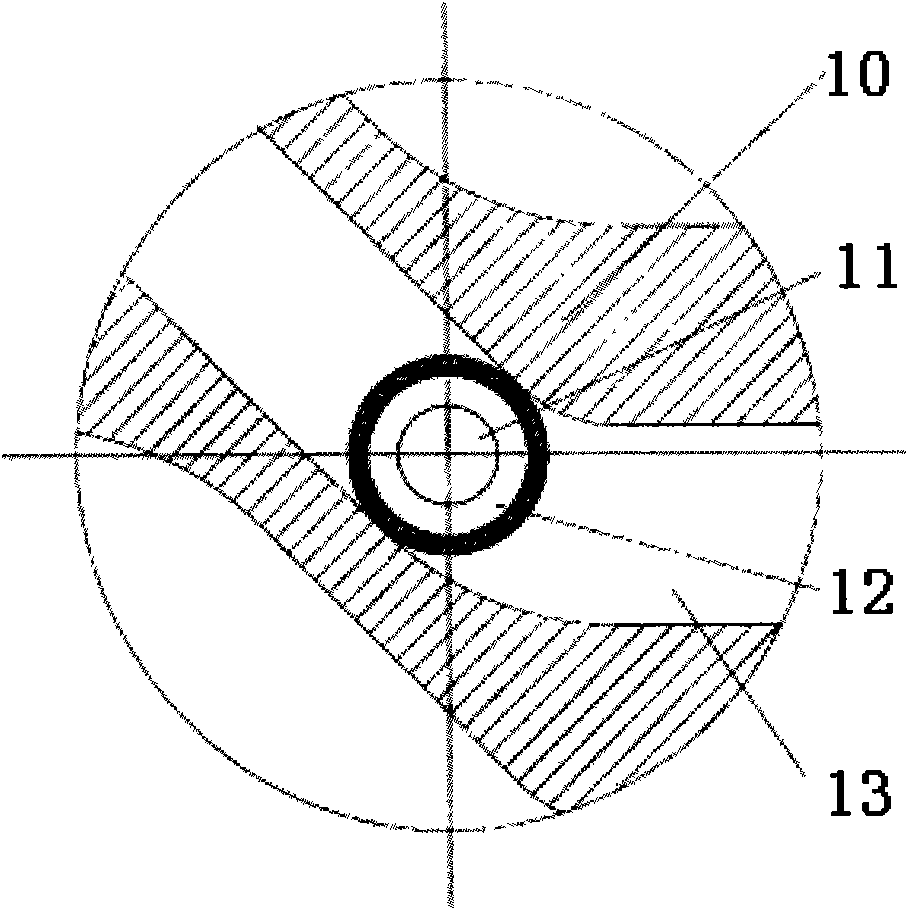

[0016] This example uses a radar probe as the rangefinder. Such as figure 1 As shown in the schematic diagram of the radar probe itinerant measurement device, the radar probe 1 is installed on the inclined rod 5 that can rotate within a certain angle along a certain point on the fixed frame 7, and the zero point of the radar probe 1 coincides with this point; the inclined rod 5 and The special-shaped screw rod 2 and the fixed mount 7 form a right triangle, and the fixed mount 8 is a side of the triangle, which is used for fixing the device and the surrounding objects; traction by a special motor 8, which drives the radar probe 1 on the inclined rod to rotate, and continuously measures the measurement point; Switch the power supply of the motor 8 to make the motor 8 reversely rotate, and drive the inclined rod 5 to reversely rotate for the measurement of the next cycle. The measurement data of the radar probe 1 is continuously transmitted to the computer, and the computer pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com