A method for analyzing the change of silicon carbide particles before and after mortar cutting

A technology of silicon carbide particles and medium silicon carbide, which is applied to fine working devices, manufacturing tools, stone processing equipment and other directions, can solve problems such as interference with silicon carbide particle measurement, damage to measuring instruments, falling iron powder, etc. Ease of operation, avoidance of waste, and the effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

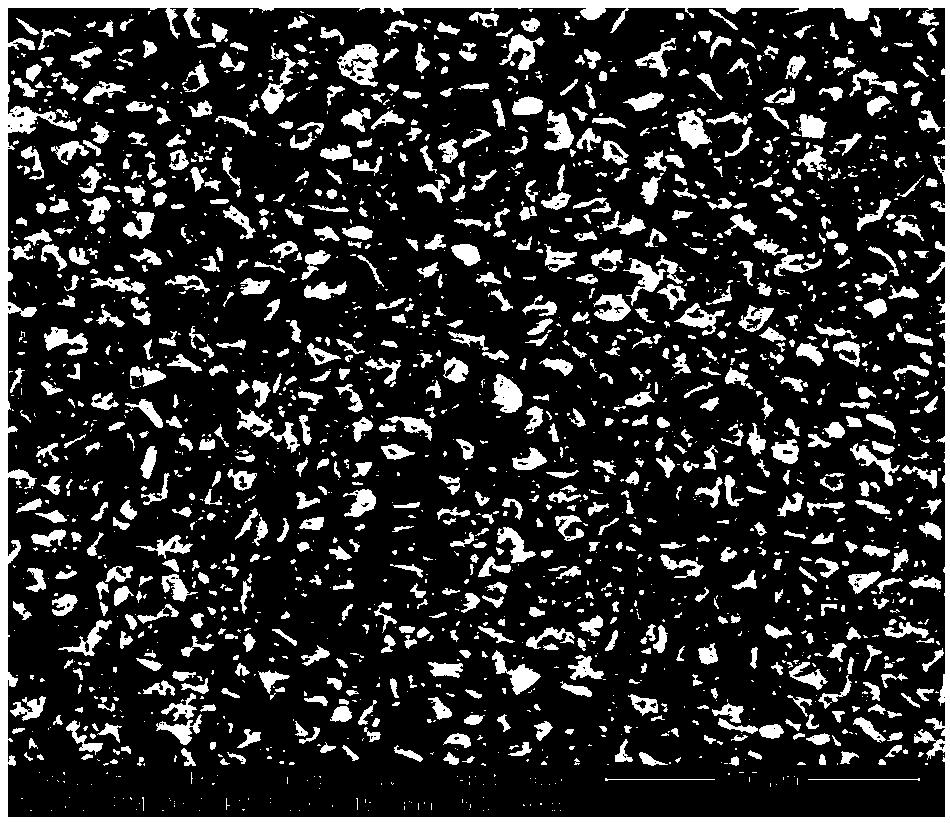

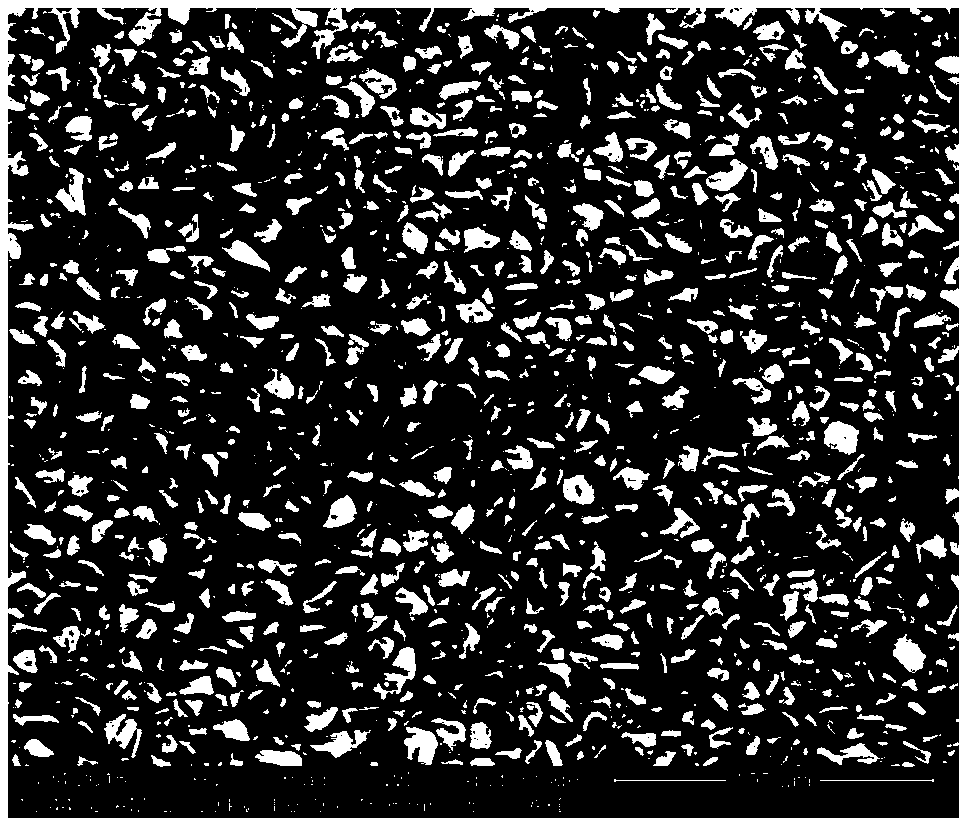

[0053] In this embodiment, the mortar used for polysilicon cutting is selected to be measured. Before the measurement, samples are taken at the cutting site, and the same batch of mortar before cutting and waste mortar after cutting are taken separately for future use. In order to facilitate the distinction, the mortar before cutting is marked as finished mortar, and the mortar after cutting is marked as waste mortar.

[0054] The method for analyzing the change of silicon carbide particles before and after mortar cutting includes the following steps:

[0055] (1) Disperse 10ml of cut waste mortar in 100ml of deionized water and stir with a magnetic stirrer;

[0056] (2) Add 200ml of sodium hydroxide solution with a concentration of 1mol / L to react for 1h, then control the speed of the centrifuge to 3500r / min, and centrifuge for 10min; after the separation is completed, wash the silicon carbide particles with water, continue to centrifuge, wash with water, and repeat 3 times;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com