Reusable three-dimensional polarized glass polarizer and glasses using same

A technology of polarized glasses and polarizers, which is applied in the direction of glasses/goggles, optics, polarizing elements, etc., which can solve the problems of shortened service life and other problems, and achieve scratch prevention, prolong service life, high scratch resistance and transmittance rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

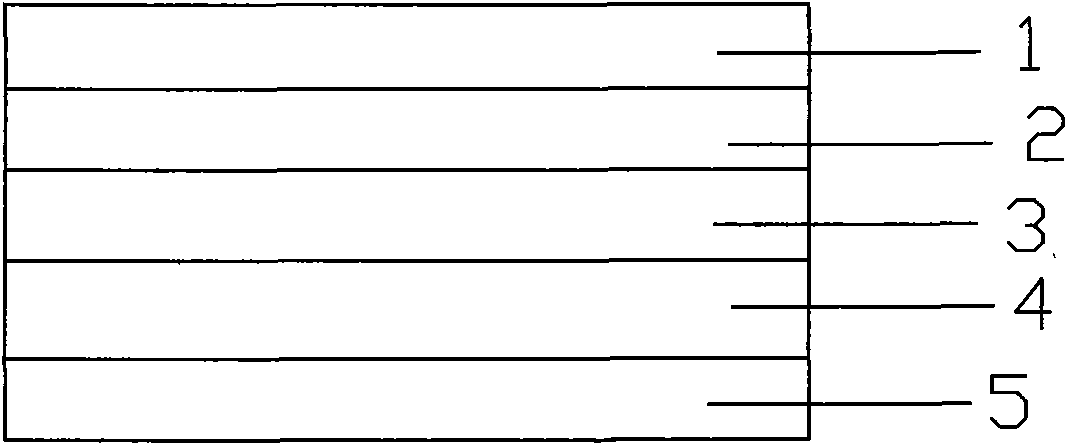

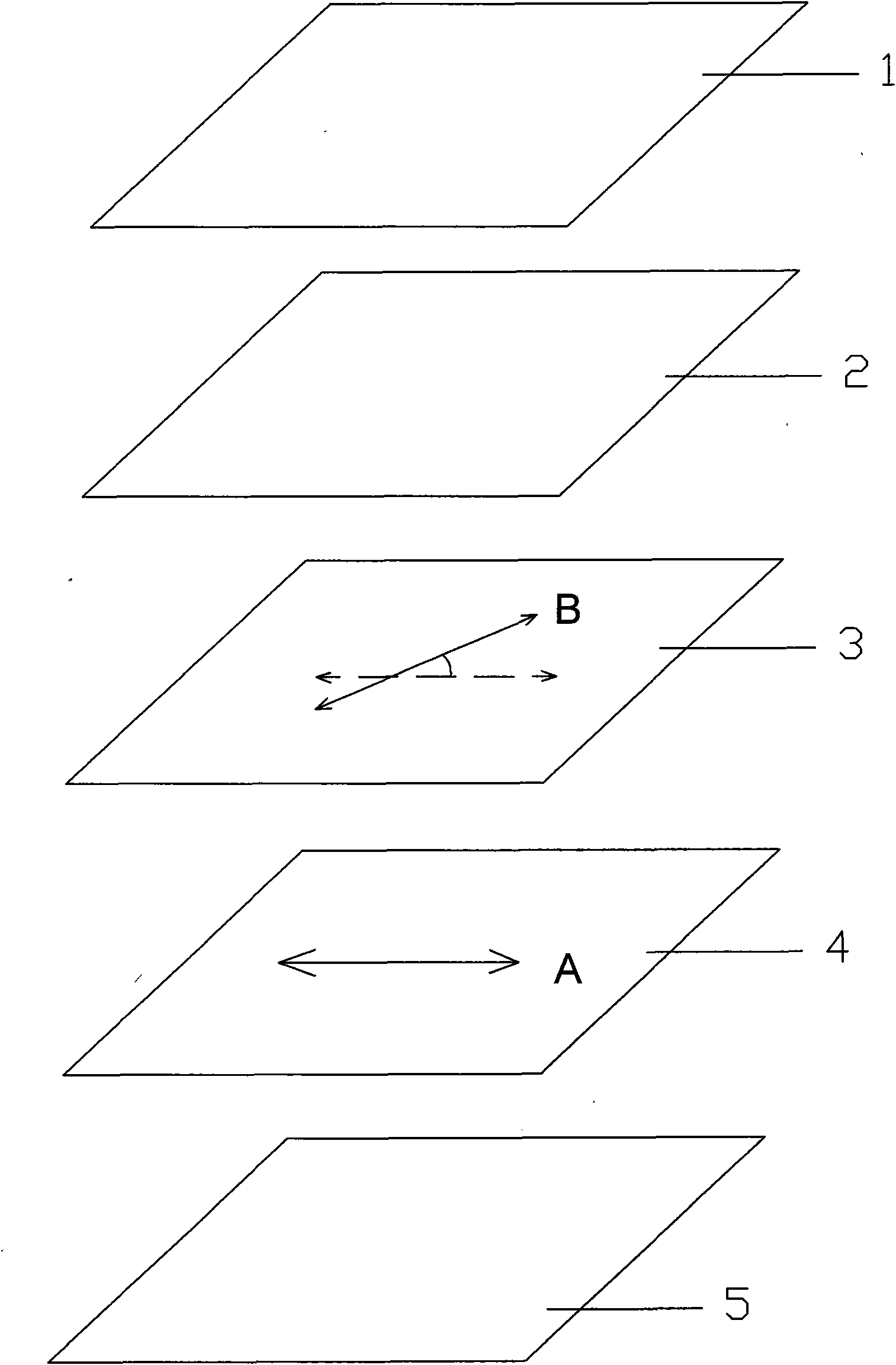

[0009] see figure 1 and figure 2 , the present invention proposes a kind of reusable three-dimensional polarizing glasses polarizer, which comprises a first protective film 1, an anti-scratch triacetate cellulose (TAC) film 2, a phase difference film 3, an anti-scratch polarizing film 4 and a second protective film 5 . The above layers are compounded together by a compound machine.

[0010] First, the definitions of the terms and symbols in the specification of the present invention will be explained.

[0011] (1) The symbol "nx" refers to the refractive index in the direction that provides the maximum in-plane refractive index (ie, the direction of the slow axis), and the symbol "ny" refers to the direction perpendicular to the slow axis (ie, the fast axis) in the same plane. direction) in the refractive index. The symbol "nz" refers to the refractive index in the thickness direction. Moreover, for example, the expression "nx=ny" not only refers to the case where nx and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com