Spiral channel column anode

A spiral flow channel and anode technology, applied in electrochemical water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as clogging, increase the adhesion area and prevent clogging. , The effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

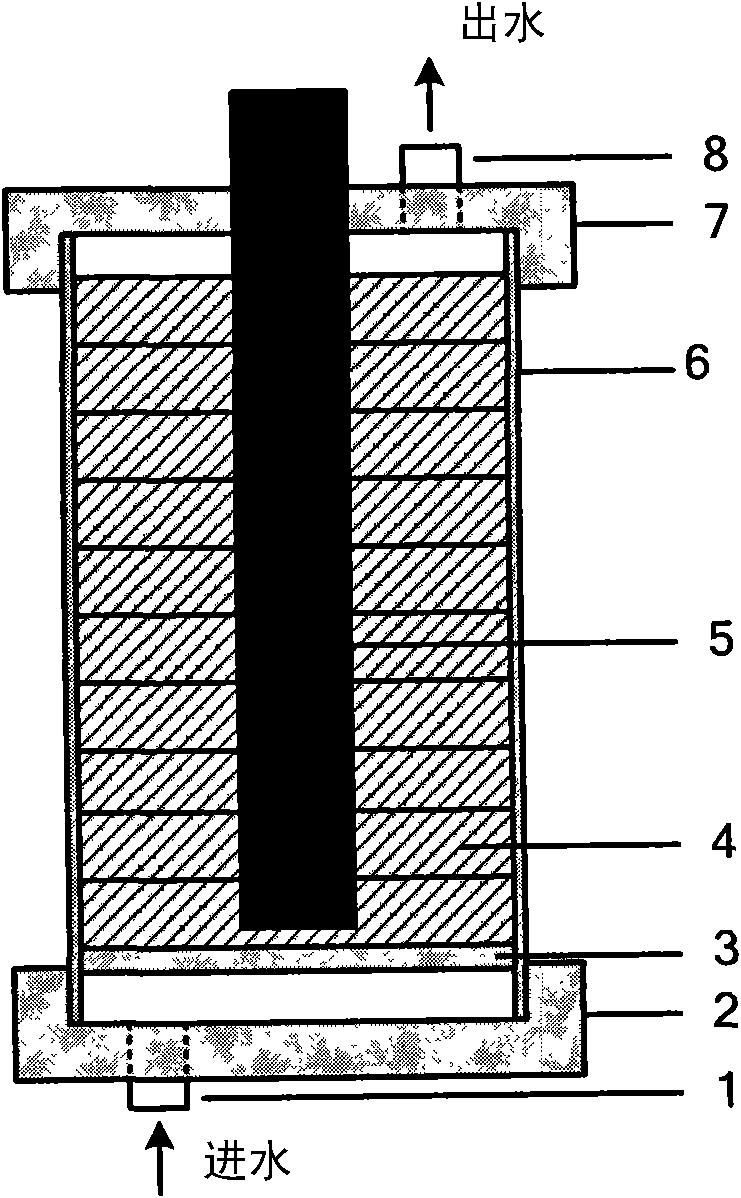

[0024] figure 1 It is a structural schematic diagram of a columnar anode with a spiral channel of the present invention. Among them, 1 is the water inlet, 2 is the bottom plate, 3 is the separator, 4 is the perforated carbon felt, 5 is the graphite rod, 6 is the proton membrane, 7 is the top plate, and 8 is the water outlet.

[0025] The two ends of the cylindrical proton membrane 6 are respectively bonded and sealed by the top plate 7 and the bottom plate 2 to form an anode chamber. At the same time, the bottom plate and the top plate are respectively provided with a water inlet 1 and a water outlet 8; On the other hand, it plays the role of supporting carbon felt; on the other hand, it plays the role of uniform water distribution; the surface of graphite rod 5 is engraved with threads, and then it is screwed into the columnar anode 6, so that the two are tightly embedded together, thereby enhancing the transmission of electrons Effect.

[0026] The working principle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com