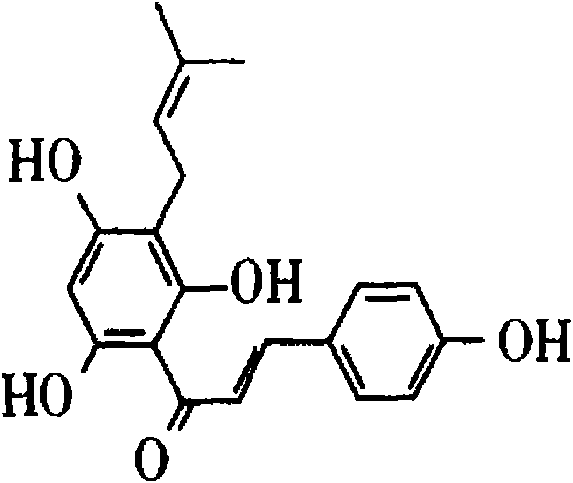

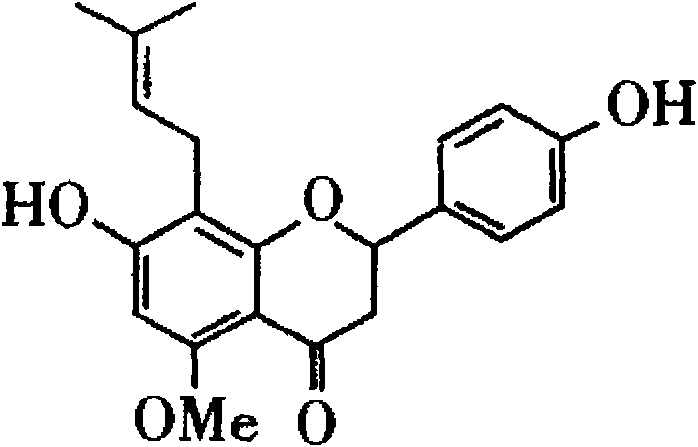

Method for preparing beer rich in xanthohumol

A technology of xanthohumol and xanthohumol ethanol, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, and beer brewing, etc. High, clear wine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

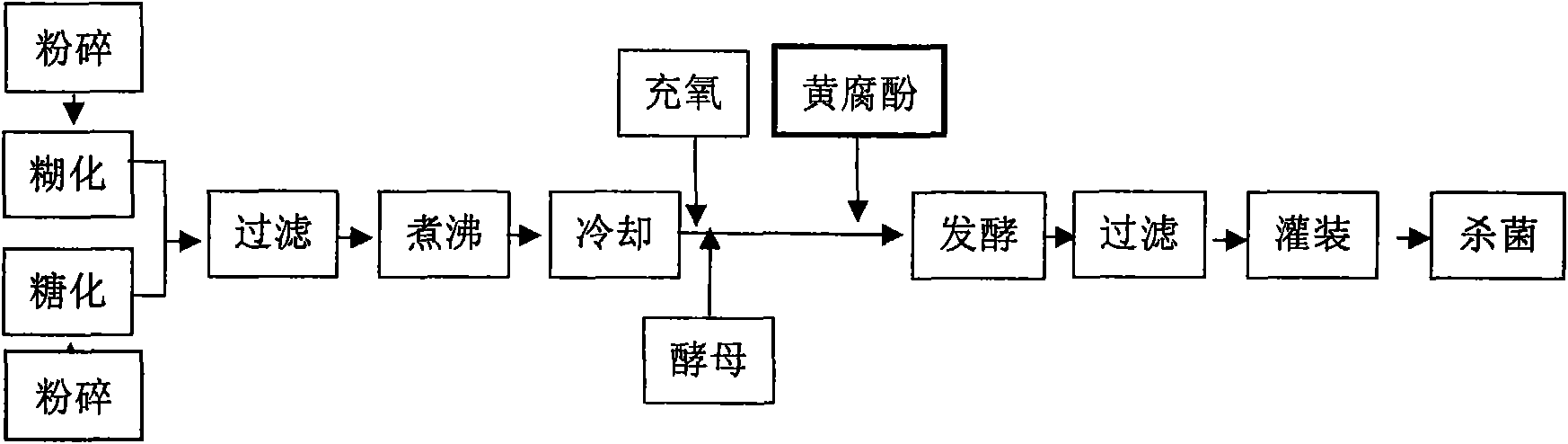

[0021] Method 1: Add to the wort:

[0022] 1. Dissolve the xanthohumol product in 95% ethanol, centrifuge at 10,000 rpm and 5°C, take the clear liquid, and detect the content of xanthohumol in it, and the content reaches 1,000-5,000 mg / L;

[0023] 2. During the wort cooling process, add the xanthohumol ethanol solution to the wort on the wort pipeline;

[0024] 3. It is also possible to dilute the ethanol solution of xanthohumol with alkaline solution according to the ratio of 1:5 to 1:10, adjust the pH value to 10 to 11, and then add it to the wort;

[0025] 4. The content of xanthohumol in the final wort is 5-50mg / L;

[0026] 5. Add yeast, after fermentation, filter, fill, and sterilize according to the normal beer production process to obtain beer rich in xanthohumol.

[0027] Method 2: Add to the fermentation broth:

[0028] 1. Dissolve the xanthohumol product in 95% ethanol, centrifuge at 10,000 rpm and 5°C, take the clear liquid, and detect the content of xanthohumol ...

Embodiment 1

[0041] Embodiment 1: brewing 100L of 12 ° P pale beer

[0042] 1. The brewing process of beer rich in xanthohumol, adding to cold wort:

[0043] 2. Beer brewing ingredients: malt 12.8kg, rice 3.2kg, brewing water 56L (gelatinization pot 13L, saccharification pot 43L), hops 70g (including bitter flower 50g, aroma flower 20g)

[0044] 3. Prepare to weigh 0.150g of the xanthohumol product (content is 70%), dissolve it with 95% edible alcohol, and accurately adjust the volume to 50ml to prepare a xanthohumol solution. The content of xanthohumol is 1895mg / L after testing .

[0045] 4. Add in the wort cooling process, the addition amount is 20ml, and the xanthohumol content in the final wort is 32mg / L.

[0046] 5. During the fermentation process, the fermentation temperature is 10°C, and when the sugar drops to 4°P, the tank is sealed and the pressure is raised to 0.10MPa. When the diacetyl is 0.07mg / L, the temperature starts to drop; the cooling rate is 0.5°C / hour, when the tempe...

Embodiment 2

[0052] Embodiment 2: Brew 100L of 12 ° P dark beer

[0053] 1. The brewing process of beer rich in xanthohumol, adding:

[0054] 2. Beer brewing ingredients: 12.0kg of malt, 5.0kg of caramel malt, 60L of brewing water, 87g of hops (including 55g of bitter flowers and 27g of fragrant flowers)

[0055] 3. Prepare to weigh 0.300g of the xanthohumol product (content is about 70%), dissolve it with 95% edible alcohol, and accurately adjust the volume to 50ml to prepare a xanthohumol solution. The content of xanthohumol is 3736mg / L.

[0056] 4. Prepare 500ml of 0.01mol / L KOH solution, measure 450ml and mix it with xanthohumol solution, adjust the pH value in it to 10, and form xanthohumol alkaline aqueous solution.

[0057] 5. During the fermentation process, the fermentation temperature is 10°C, and when the sugar drops to 4°P, the tank is sealed and the pressure is raised to 0.10MPa. When the diacetyl is 0.07mg / L, the temperature starts to drop; the cooling rate is 0.5°C / hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com