Brewing method of ice cherry wine

A technology for cherry wine and cherries, which is applied in the directions of microorganism-based methods, alcoholic beverage preparation, biochemical equipment and methods, etc., can solve the problem of destroying nutrients and nutritional functions, and cannot adapt to the fermentation temperature and other fermentation conditions of cherries. Unsatisfactory effect and other problems, to achieve the effect of protecting effective nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] First use the programmed ventilation and drying method to reduce the moisture content of the cherries to below 60%; then combined with the step-by-step freezing method, keep at -4°C for 12 hours; adjust the temperature to -6°C and keep for 24 hours; finally adjust the temperature to -10°C for 12 hours , broken, juiced at -12°C, added with 0.20% pectinase, and enzymolyzed for 3 hours; after enzymolysis, 1.5% was added to Saccharomyces cerevisiae SC203 for fermentation, the fermentation temperature was 10°C, and the fermentation time was 75 days; aged at 5°C for 3 months; 0.5 ℃, treatment for 15 days, clarification agent clarification; primary filtration, membrane filtration; sterilization; physical and chemical testing; packaging. Finally, a series of ice cherry wines with rich aroma and full body are brewed.

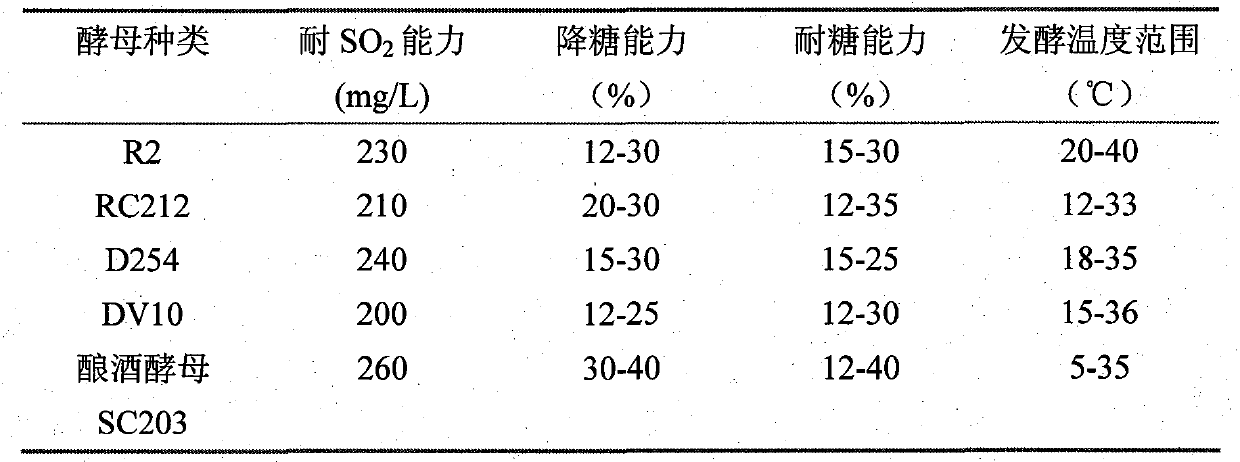

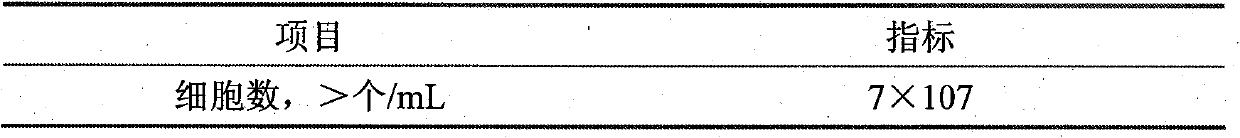

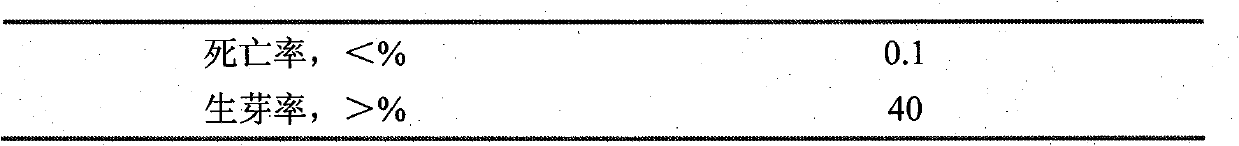

[0075] Table 4 Comparison of four groups of yeast fermentation performance (10℃)

[0076]

[0077] It can be seen from Table 4 that Saccharomyces cerevisiae S...

Embodiment 2

[0079] First use the programmed ventilation and drying method to reduce the moisture content of the cherries to below 60%; then combined with the step-by-step freezing method, keep at 0°C for 36 hours; adjust the temperature to -4°C and keep for 30 hours; finally adjust the temperature to -7°C for 24 hours. Crush, squeeze juice at -7°C, add 0.05% pectinase, and enzymatically hydrolyze for 4 hours; after enzymolysis, insert 0.5% into Saccharomyces cerevisiae SC203 for fermentation, the fermentation temperature is 20°C, and the fermentation time is 30 days; aging for 2 months at 14°C; 2 ℃, treatment for 10 days, clarification with clarifier; primary filtration, membrane filtration; sterilization; physical and chemical testing; packaging. Finally, a series of ice cherry wines with rich aroma and full body are brewed.

[0080] Table 5 Comparison of four groups of yeast fermentation performance (20℃)

[0081]

[0082] From the comparison of Saccharomyces cerevisiae SC203 and th...

Embodiment 3

[0084] 25Kg of cherries, wash, sterilize, drain, dry at 20°C for 10h, reduce the water content of the cherries to below 60%, adjust the temperature to -4°C, keep for 12h, adjust the temperature to -6°C, keep for 24h, then adjust the temperature to -10 ℃, lasted 12h, crushed, squeezed juice at -12℃, added 15g pectinase, treated for 4h, inoculated with Saccharomyces cerevisiae SC203 about 3.6×10 10 1, fermented at 20°C for 30 days, aged at 5°C for 3 months, treated at 0.5°C for 15 days, clarified with a clarifier, prefiltered, membrane filtered, sterilized, and packaged. Finally, a high-quality series of ice kirsch with pure, elegant and harmonious cherry fruit aroma and bouquet is brewed.

[0085] Table 6 Sensory evaluation results of ice cherry wine fermented by two kinds of yeasts

[0086]

[0087] It can be seen from Table 6 that the ice cherry wine fermented by wine yeast 1450 is dull in color, not prominent in fruit aroma, and not clear in typicality, while the ice che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com