Air supply valve and component transportation device

A gas supply and gas technology, which is applied to valve devices, valve operation/release devices, lift valves, etc., can solve the problems of large gas supply valves, increased power consumption, hysteresis, and increased driving load, etc., to reduce Delay of start and stop, reduction of ventilation resistance, effect of reducing drive load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]

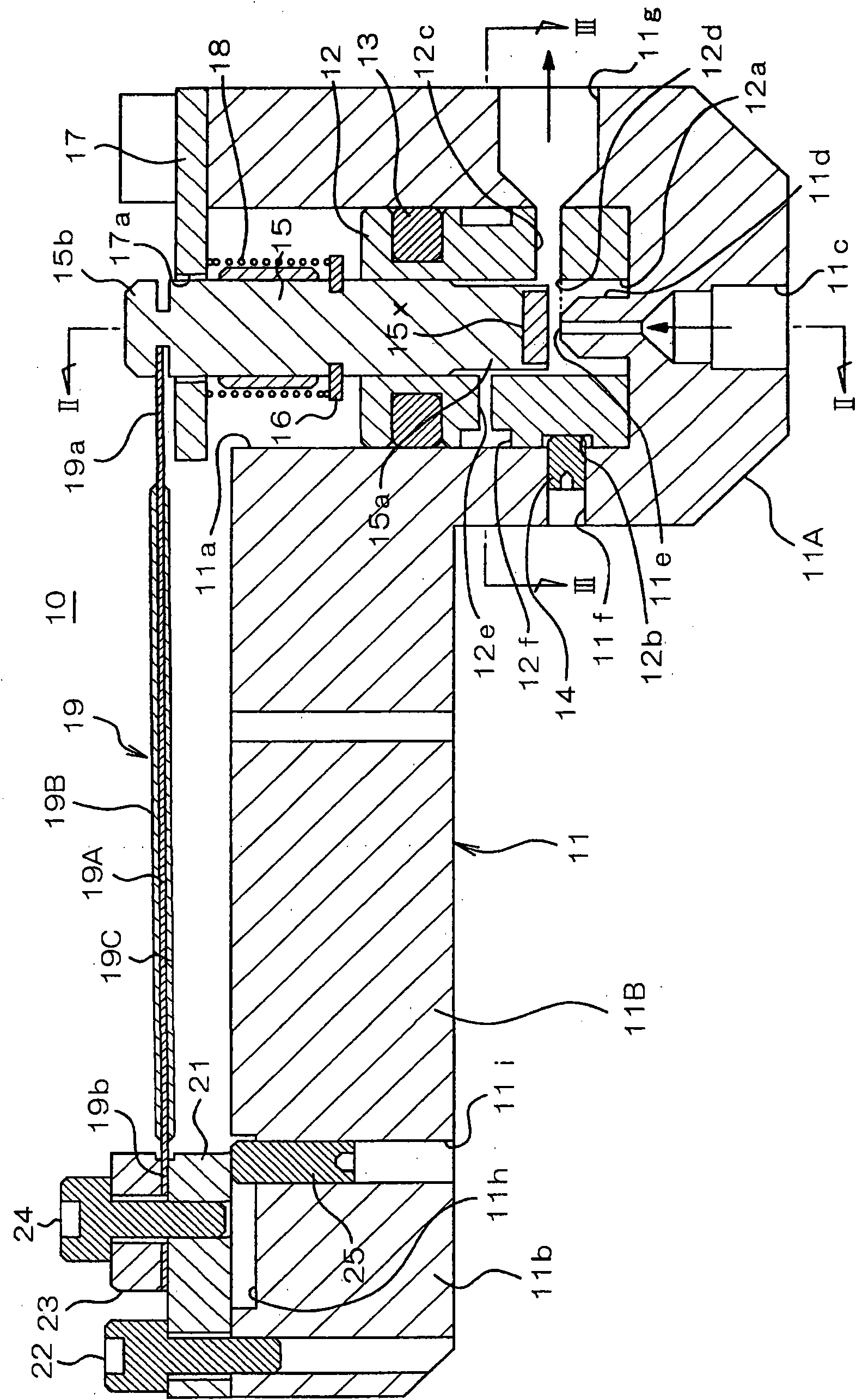

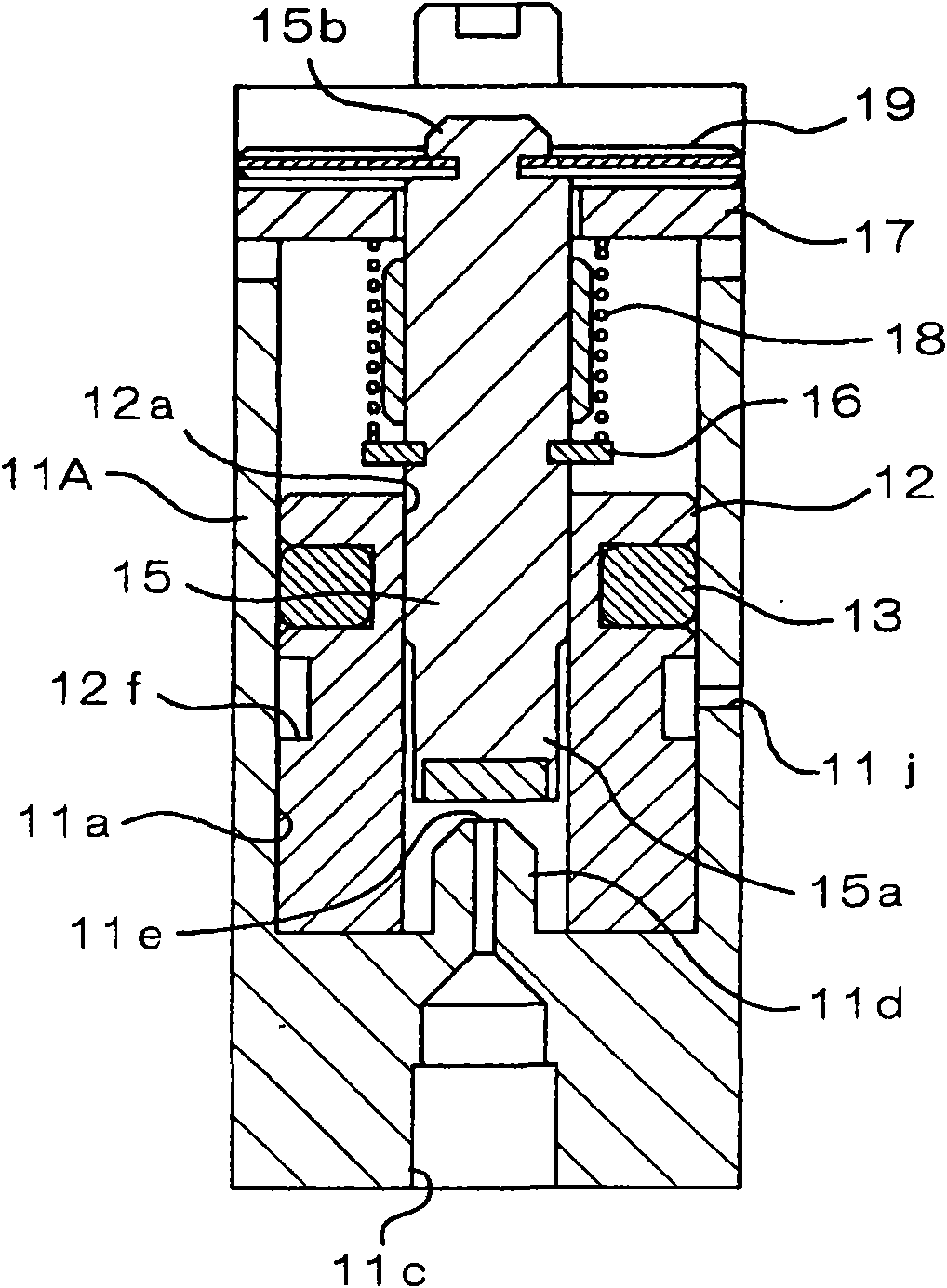

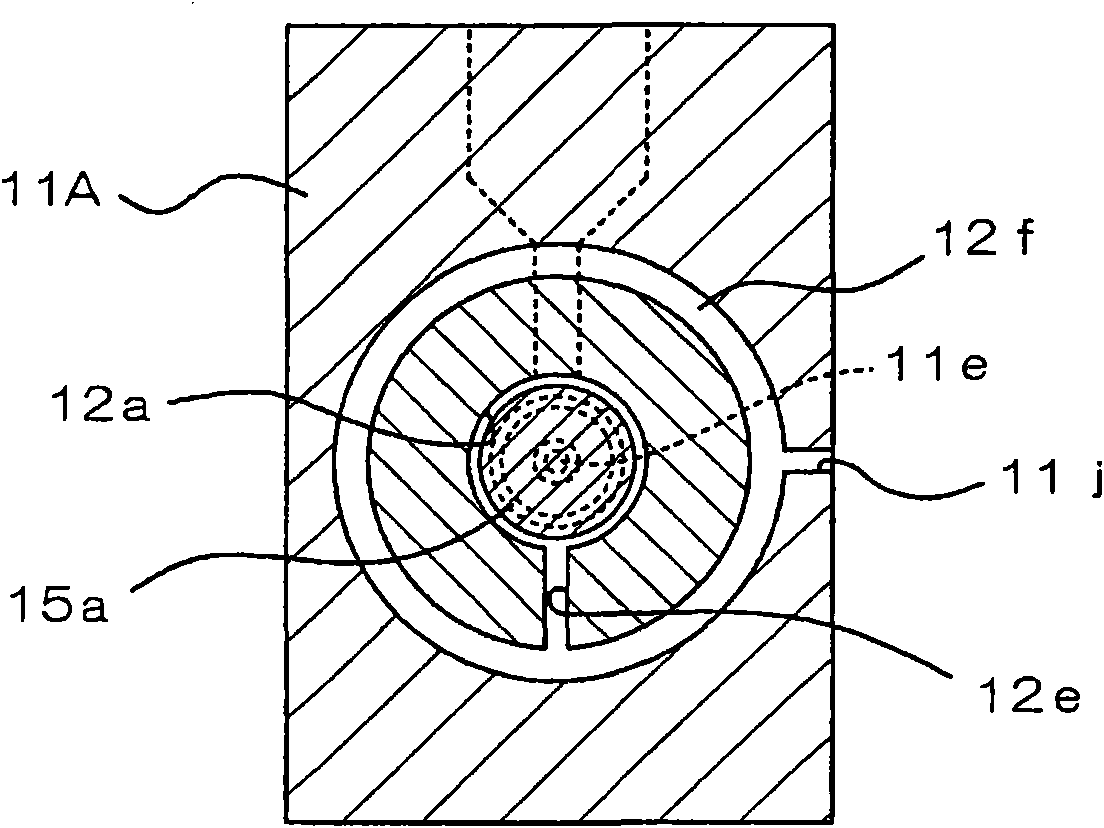

Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic longitudinal sectional view showing the internal structure of the first embodiment of the gas supply valve of the present invention, figure 2 Indicates the same as the first embodiment figure 1 Schematic cross-sectional view of an orthogonal cross-section ( figure 1 sectional view of line II-II), image 3 is a schematic cross-sectional view of the first embodiment ( figure 1 sectional view of line III-III).

[0017]

The gas supply valve 10 has a housing 11 made of metal, synthetic resin, or the like, and the housing 11 is provided with a main structure portion 11A and an extension portion 11B, the main structure portion 11A having a cylindrical recessed hole 11a inside; the extension portion The 11B is configured in a beam shape linearly extending laterally from the main structure portion 11A, and has a fixing portion 11b at the distal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com