Multi-gap liquid crystal display panel and manufacturing method thereof

A technology of liquid crystal display panels and manufacturing methods, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as complex processes, reduce brightness of liquid crystal displays, etc., and achieve the effect of solving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

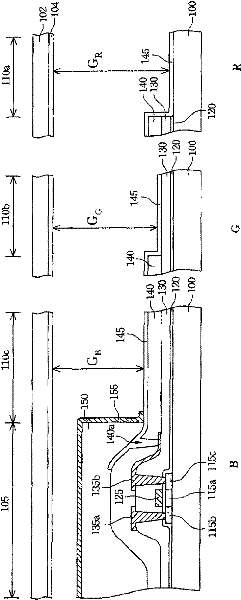

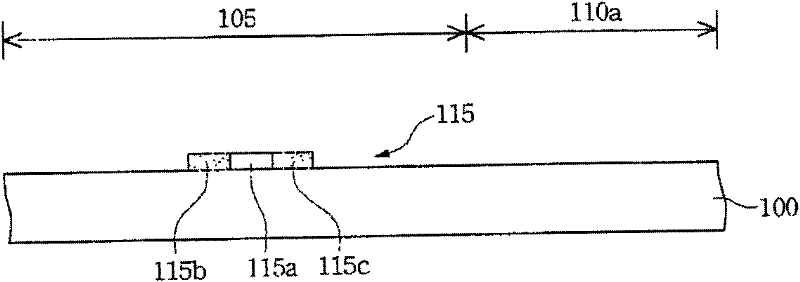

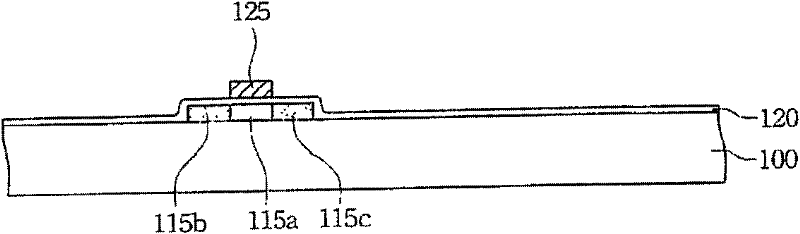

[0065] Please refer to Figure 1A , which shows a cross-sectional schematic diagram of a pixel structure of a transflective liquid crystal display according to an embodiment of the present invention. exist Figure 1A , the cross-sectional schematic diagram of red (R), green (G), and blue (B) three-color pixels is marked. Since the wavelengths of the three primary colors are red, green and blue in order from large to small, the height difference between the transmissive region 110a and the reflective region 105 of the red pixel (R) is the largest, at least the gate dielectric layer 120 , the sum of the thicknesses of the dielectric layer 130 , the passivation layer 140 and the organic planarization layer 150 . Secondly, the height difference between the transmissive region 110 b and the reflective region 105 of the green pixel (G) is at least the sum of the thicknesses of the protection layer 140 and the organic flat layer 150 . The minimum is the height difference between the...

Embodiment 2

[0074] Please refer to Figure 2A , which shows a cross-sectional schematic diagram of a pixel structure of a transflective liquid crystal display according to another embodiment of the present invention. exist Figure 2A , the cross-sectional schematic diagram of red (R), green (G), and blue (B) three-color pixels is marked. Similarly, since the wavelengths of the three primary colors of light are red, green, and blue in descending order, the height difference between the transmissive area 210a and the reflective area 205 of the red pixel (R) is the largest, at least for the gate interlayer. The total thickness of the electrical layer 220 , the passivation layer 245 and the organic planarization layer 260 . Secondly, the height difference between the transmissive area 210b and the reflective area 205 of the green pixel (G) and the blue pixel (B) is at least the thickness of the organic flat layer 260 .

[0075] Taking the red pixel as an example, the flow of a method for m...

Embodiment 3

[0080] In Embodiment 1 and Embodiment 2, the transparent electrode directly electrically connected to the drain metal is formed first, and then the reflective electrode directly electrically connected to the transparent electrode is formed. According to other embodiments, the reflective electrode directly electrically connected to the drain metal may also be formed first, and then the transparent electrode directly electrically connected to the reflective electrode may be formed. The present invention can also be applied to a transmissive liquid crystal display, forming a transparent electrode instead of the reflective electrode 265 .

[0081] Please refer to Figure 3A-3B , which shows a cross-sectional structural schematic diagram of a process flow of a manufacturing method of a pixel structure of a transflective liquid crystal display according to another embodiment of the present invention. because Figure 3A previous process and Figures 1A-1D Same, no more details her...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com