Metal PTC electric heating tube component of air conditioner and manufacturing method thereof

A technology of electric heating tube and manufacturing method, which is applied in the direction of heating element shape, etc., can solve problems such as unreasonable structure, and achieve the effects of long working life, long heating life, and small power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described again below in conjunction with embodiment and accompanying drawing thereof

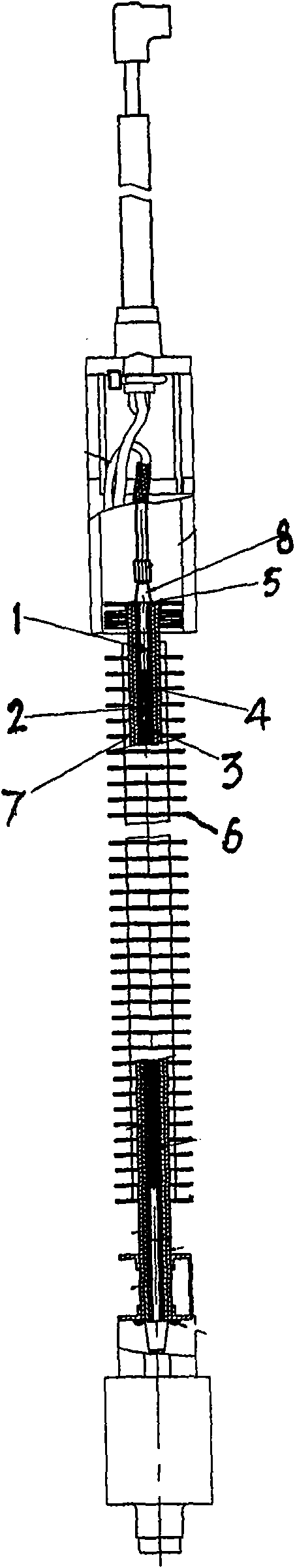

[0048] see figure 1 , an air-conditioning metal PTC electric heating tube assembly, the wound PTC heating wire 2 with inherent conductive rod 1 at both ends is placed in the center of copper-plated iron pipe 3, and the conductive rod 1 at both ends of the wound PTC heating wire 2 is partly copper-plated Outside the iron pipe 3, the inside of the copper-plated iron pipe 3 is filled with magnesium oxide powder 4 as a heat-conducting insulating powder, and the wound PTC heating wire 2 is tightly pressed in the center of the magnesium oxide powder 4 in the copper-plated iron pipe 3, and the copper-plated iron pipe 3 There are several aluminum tubes 7 of aluminum cooling fins 6 in the jacket of the expansion sleeve, that is, the copper-plated iron tube 3 is closely matched with the aluminum tube 7, the aluminum tube 7 is closely matched with the aluminum heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com