Method of controlling a rail transport system for conveying bulk materials

A technology of track and track movement, applied in the field of train system, which can solve the problem of unobtrusive aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will now be described more fully hereinafter with reference to the accompanying drawings, in which embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, the embodiments presented are provided here so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

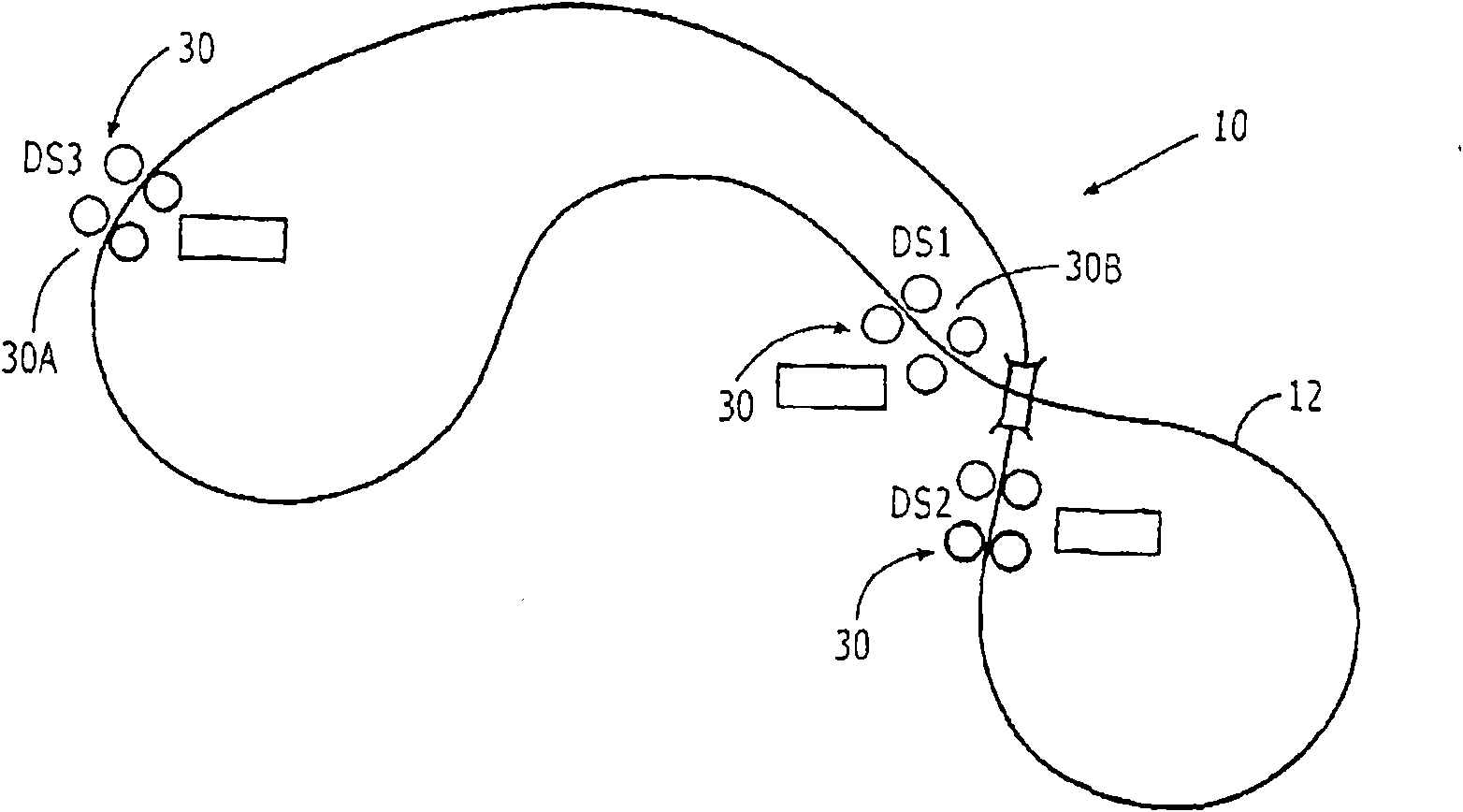

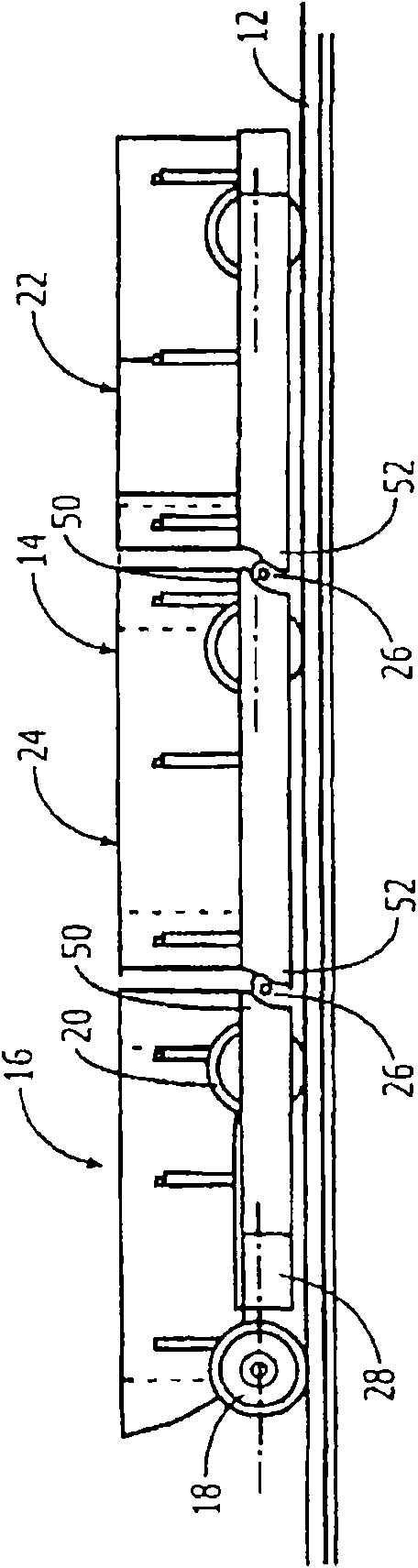

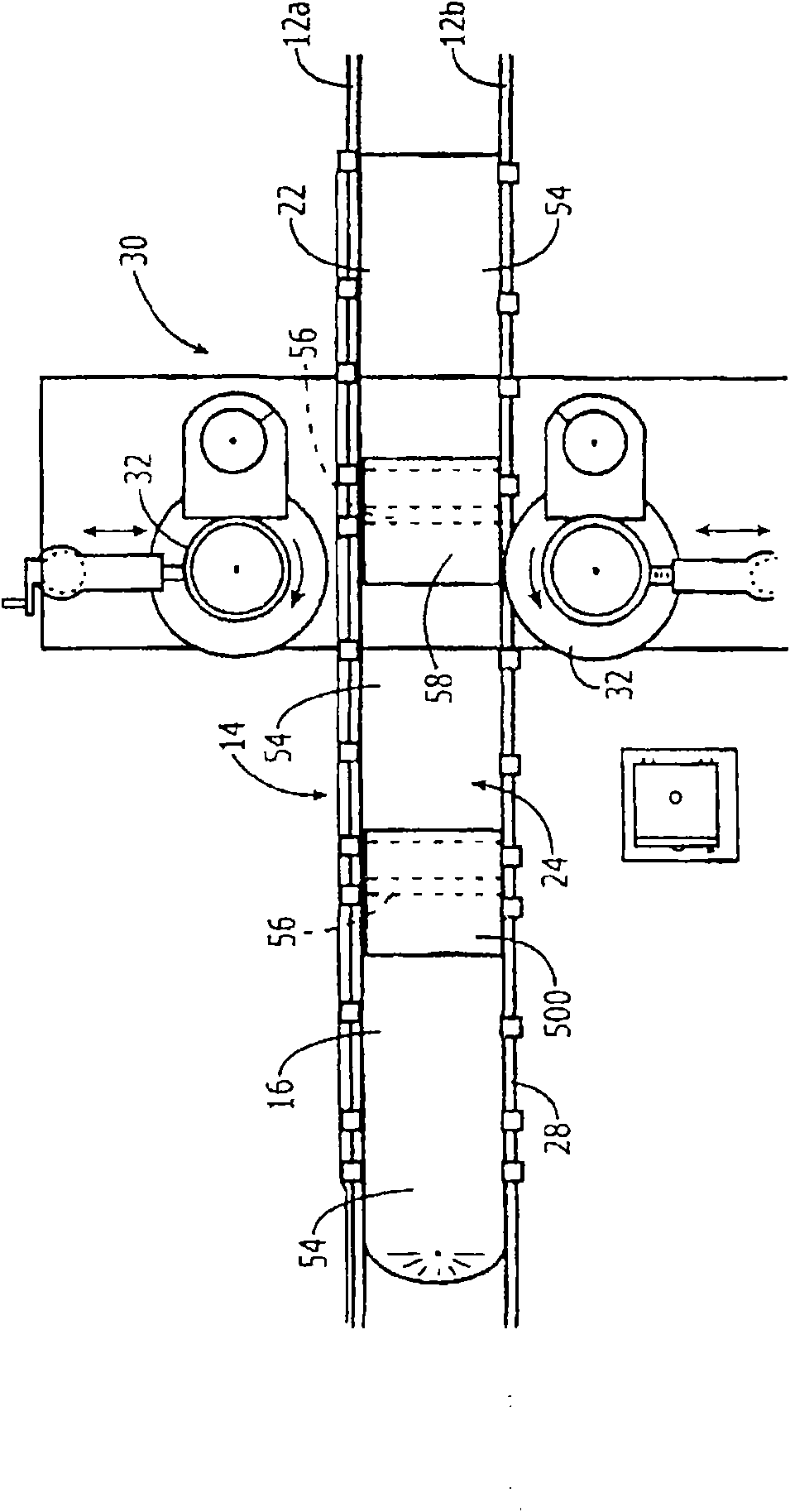

[0031] By way of example, using Rail-Veyor here TM The system describes a control system consistent with the teachings of the present invention. Other applications may include: underground mining work, where loading trains are stacked on top of an inverted empty return train, which reduces the horizontal profile; and applications where the trains are connected in a continuous loop like conventional conveyors, without belt tensioning issues and Potential fire hazard from drive slip. As will occur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com