Load drive device

一种负载驱动、电气负载的技术,应用在用电装置、输出功率的转换装置、电池/燃料电池控制装置等方向,能够解决噪音、电池产生振动等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

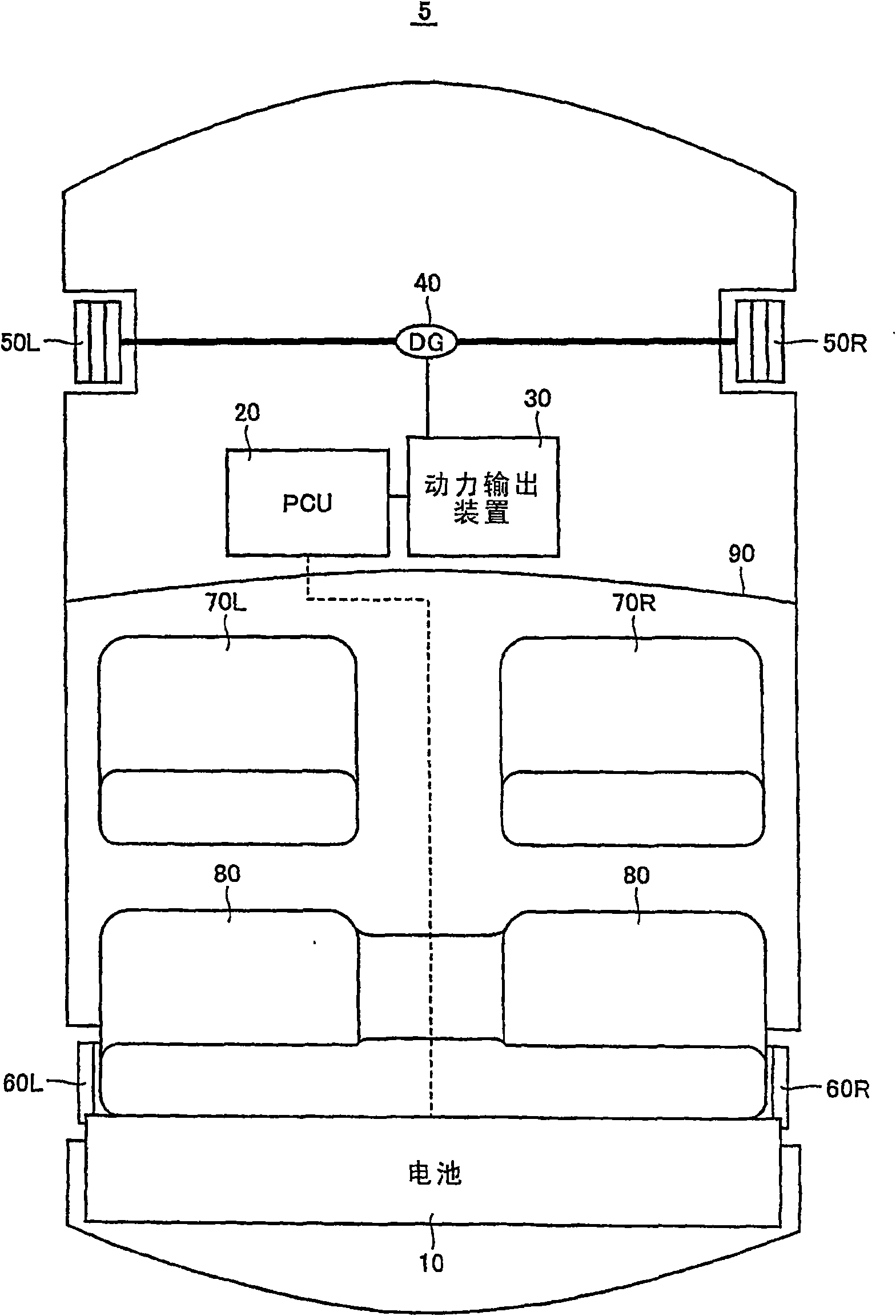

[0042] figure 1 It is a schematic block diagram showing the overall configuration of a hybrid vehicle shown as an example of installation of the load driving device in the present invention.

[0043] refer to figure 1 , the hybrid vehicle 5 includes a battery 10, a PCU (Power Control Unit) 20, a power output device 30, a differential gear (DG: Differential Gear) 40, front wheels 50L, 50R, rear wheels 60L, 60R, front seats Chairs 70L, 70R and rear seat 80.

[0044] The battery 10 is arranged behind the rear seat 80 . Furthermore, battery 10 is electrically connected to PCU 20 . The PCU 20 is arranged, for example, using the lower regions of the front seats 70L, 70R, that is, the underfloor region. The power output device 30 is arranged in the engine compartment on the front side of the instrument panel 90 . PCU 20 is electrically connected to power output device 30 . The power output device 30 is connected to the DG40.

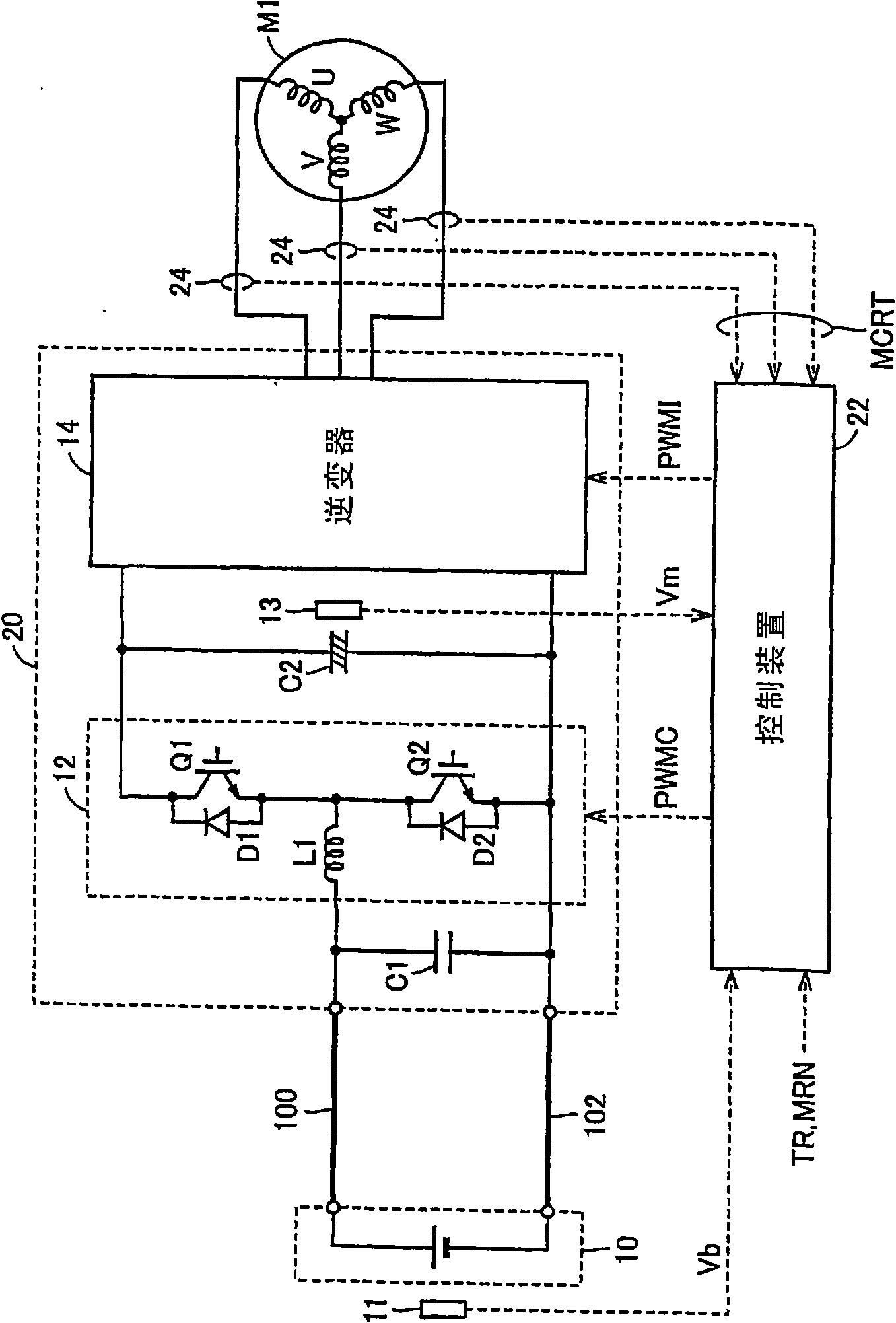

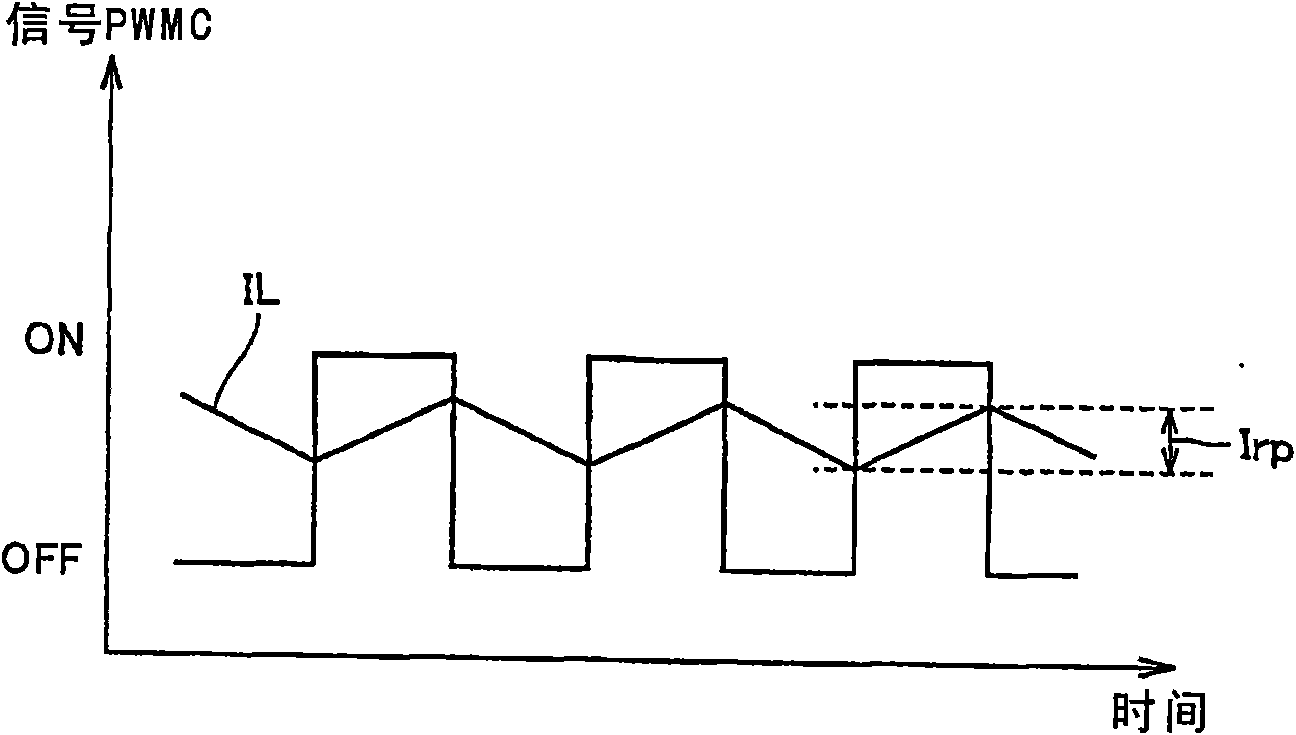

[0045] Battery 10 as a DC power supply is constitu...

Embodiment approach 2

[0125] Figure 11 It is a perspective view of a hybrid vehicle 5 to which the power cable wiring structure in Embodiment 2 of the present invention is applied.

[0126] refer to Figure 11 , in the hybrid vehicle 5, the latch outer reinforcement 200L and the door belt line reinforcement 400 forming a part of the left side of the vehicle in the vehicle width direction extend in the vehicle front-rear direction. The latch outer reinforcement 200L and the door belt line reinforcement 400 constitute a vehicle left side frame member.

[0127] In this vehicle body structure, a part of the section of the power cable 102 along the vehicle front-rear direction is arranged along the inner side surface of the buckle outer reinforcement 200L in the vehicle width direction. In addition, the section of the part of the power cable 102 and Figure 8 As described above, it is arranged in a space formed between the vehicle width direction inner surface of the latch outer reinforcement 200L a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com