Remote fault diagnosis system of infrared axle temperature detection station

A fault diagnosis system and detection station technology, applied in railway vehicle shape measuring instruments, railway car body components, railway auxiliary equipment, etc., can solve the problems of railway reputation loss, train failure, large workload and cost, and achieve compression failure Delay, compress the effect of processing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0048] A specific embodiment of the present invention is as follows:

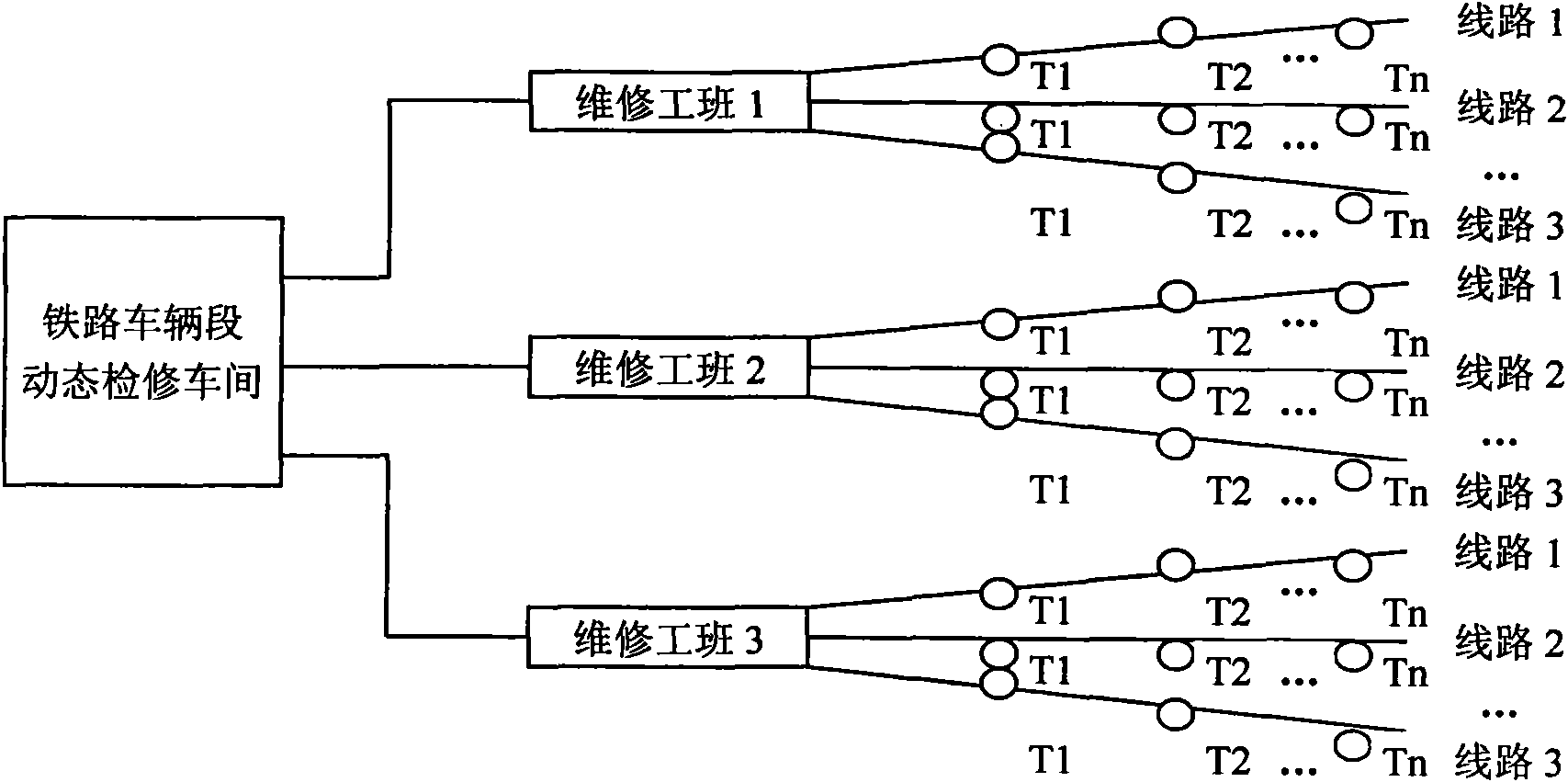

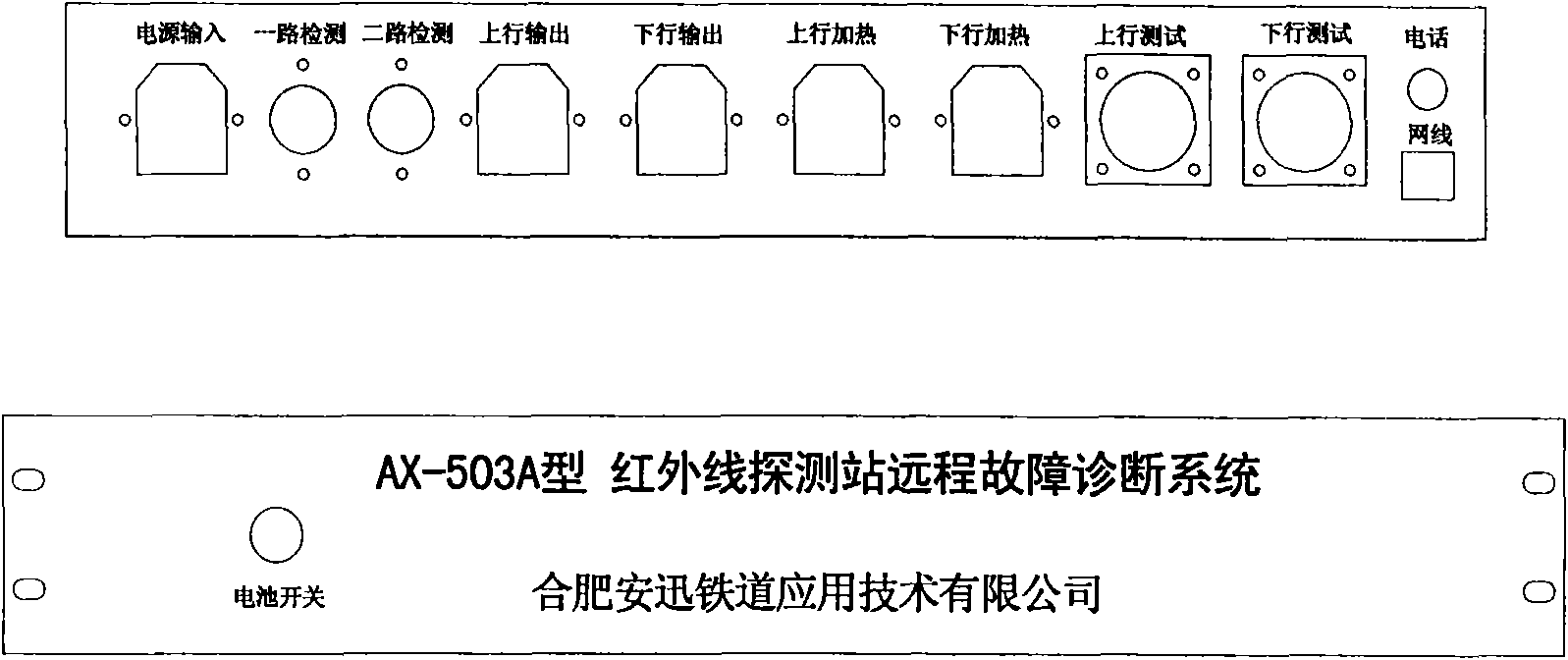

[0049] Such as Figure 1-Figure 12 Shown:

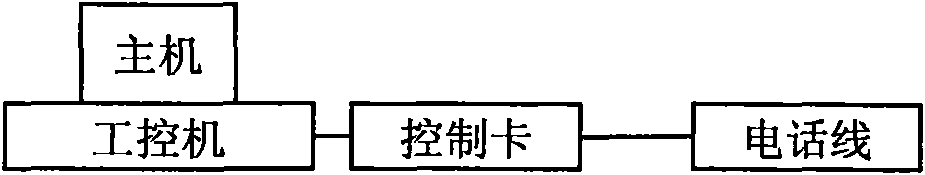

[0050] The remote fault diagnosis system of the infrared shaft temperature detection station includes a main station and a substation. The main station is installed in the dynamic maintenance workshop of the railway depot and maintenance workers along the line, and the substation is installed in the infrared shaft temperature detection station along the railway line; between the main station and the substation, The host and the extension are connected through the telephone network;

[0051] The host is composed of an industrial computer and an industrial computer control card, and the industrial computer control card includes a ringing detection circuit, an off-hook circuit, and a transceiver controller. CPU module, error code test circuit, RS232 interface, level conversion circuit; industrial computer control card and industrial computer serial communication co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com