All-in-one machine integrated with heat and cold sources

An all-in-one machine, cold and heat source technology, applied in the direction of refrigerators, compressors with multiple condensers, compressors, etc., can solve the problem that the unit cannot supply cooling and heating at the same time, the environment pollution is also large, and the energy consumption Great waste and other issues, to achieve the best overall energy efficiency, reduce waste heat and waste cold emissions, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

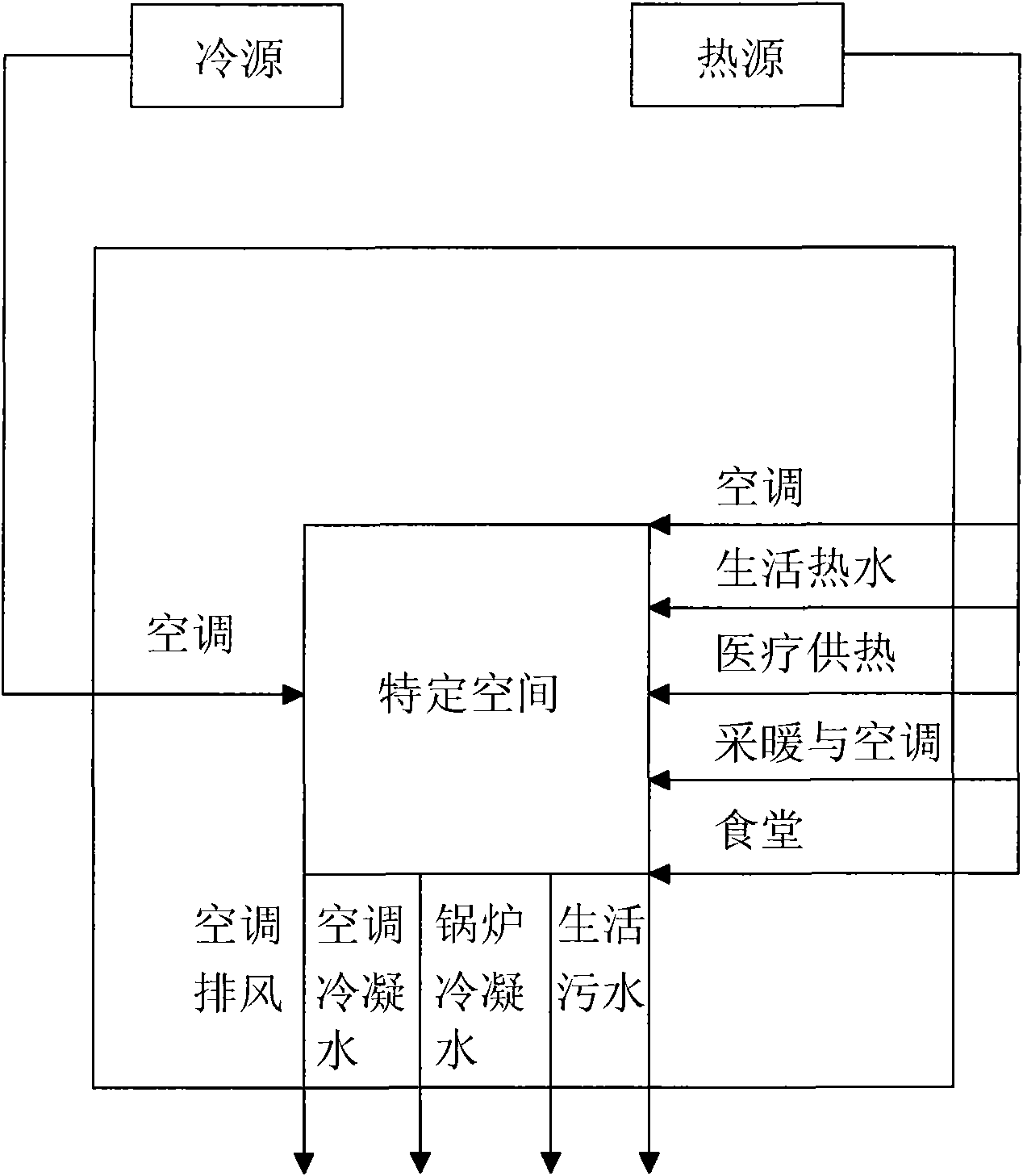

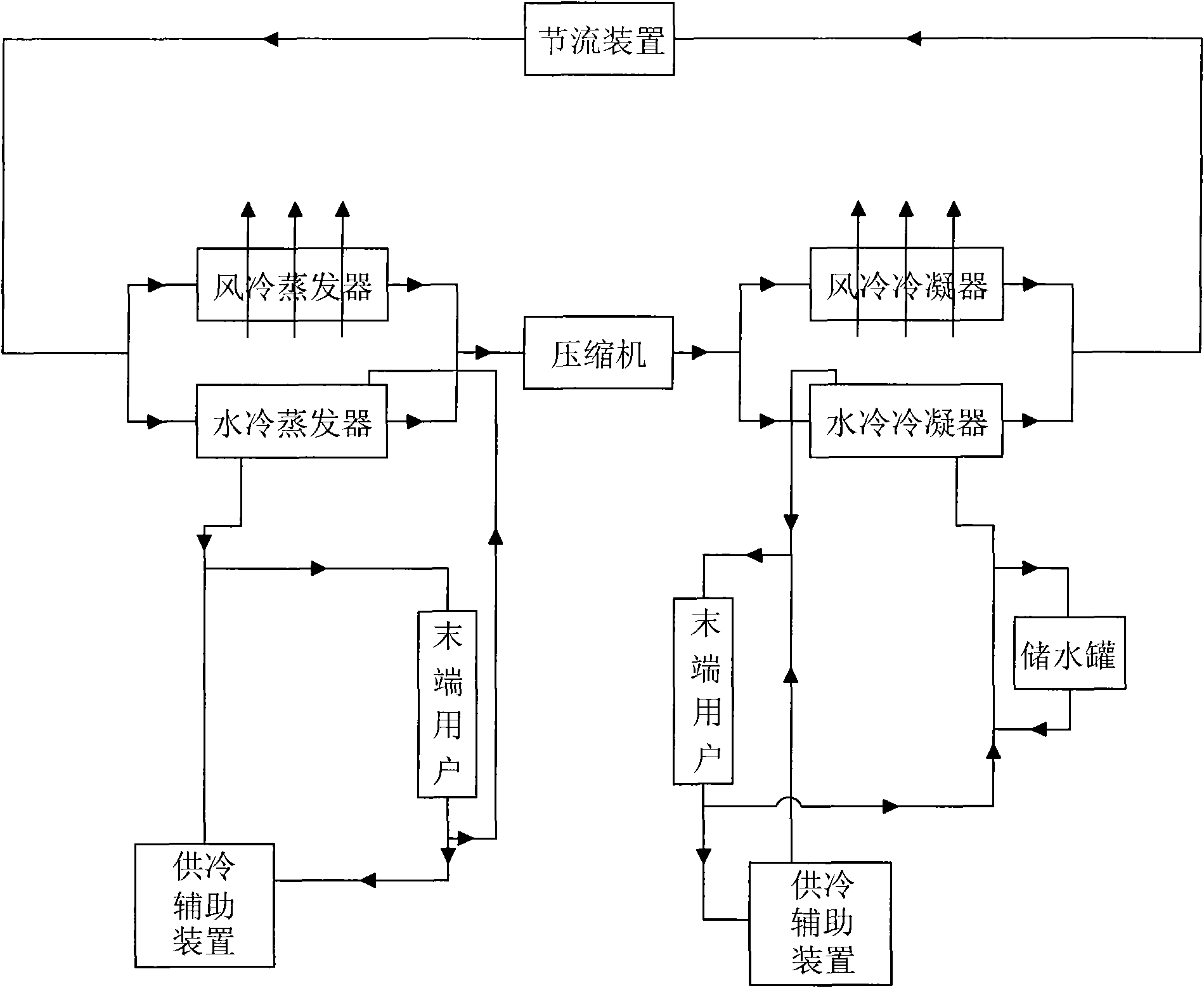

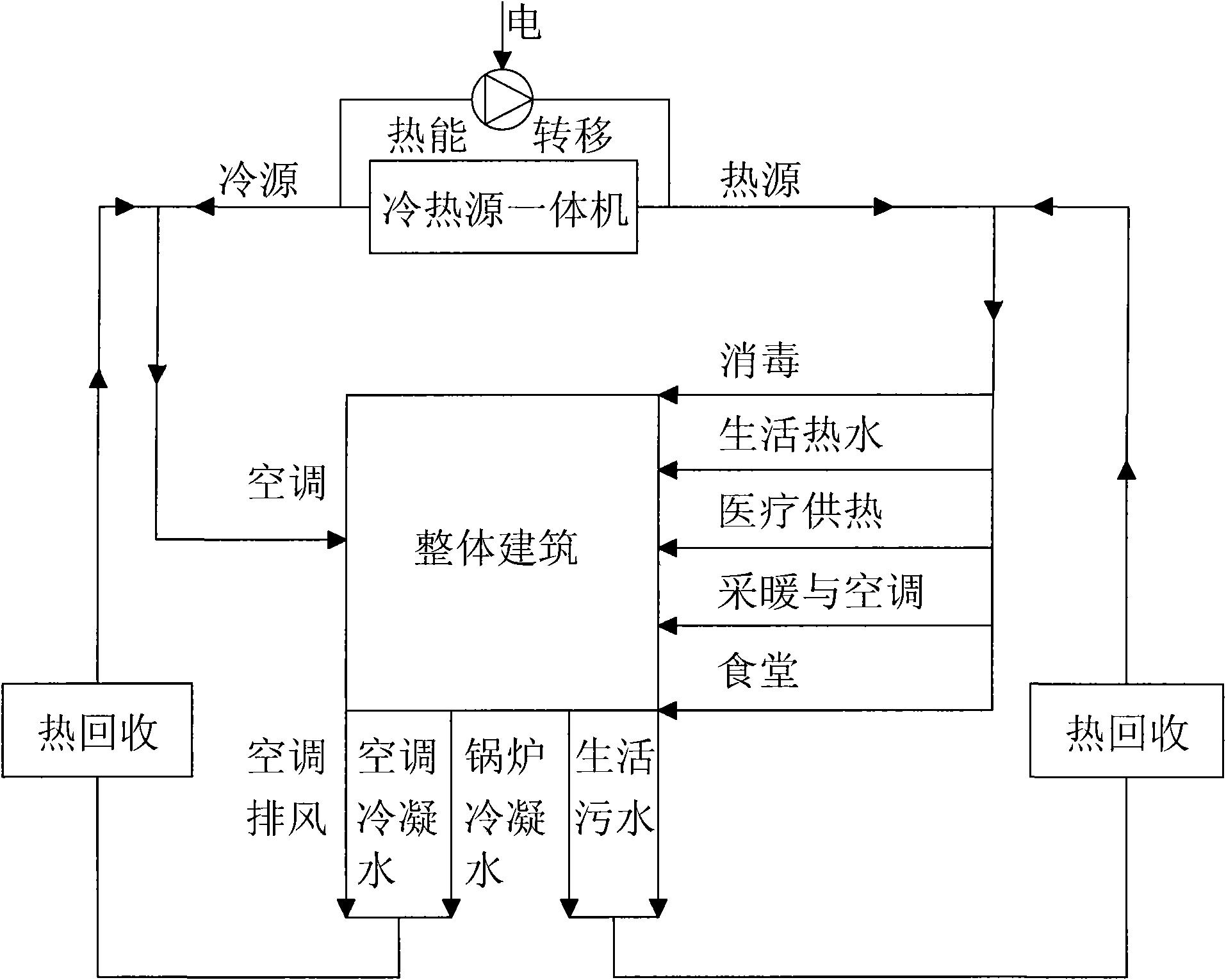

[0019] Embodiment one: see Figure 1 to Figure 3 As shown, a cold and heat source integrated machine includes a compressor, the high-pressure outlet end of the compressor is connected to the condenser, the outlet end of the condenser is connected to the inlet end of the throttling device, and the throttling device The outlet end of the evaporator is connected to the evaporator, the outlet end of the evaporator is connected to the low-pressure inlet end of the compressor, the condenser is composed of a water-cooled condenser and an air-cooled condenser in parallel, and the evaporator is composed of a water-cooled evaporator and an air-cooled evaporator in parallel, one group of fluid passages of the water-cooled condenser is connected to the throttling device, another group of fluid passages is connected to the first circulation device, one group of fluid passages of the water-cooled evaporator is connected to the The low-pressure inlet port of the compressor, and another set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com