Blade-shaped circuit breaker

A circuit breaker and blade-shaped technology, which is applied in the field of blade-shaped circuit breakers, can solve the problems of reduced insulation performance, large overall size, and difficulty in miniaturization, etc., and achieve the effect of improving electrical performance and increasing the electrical contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

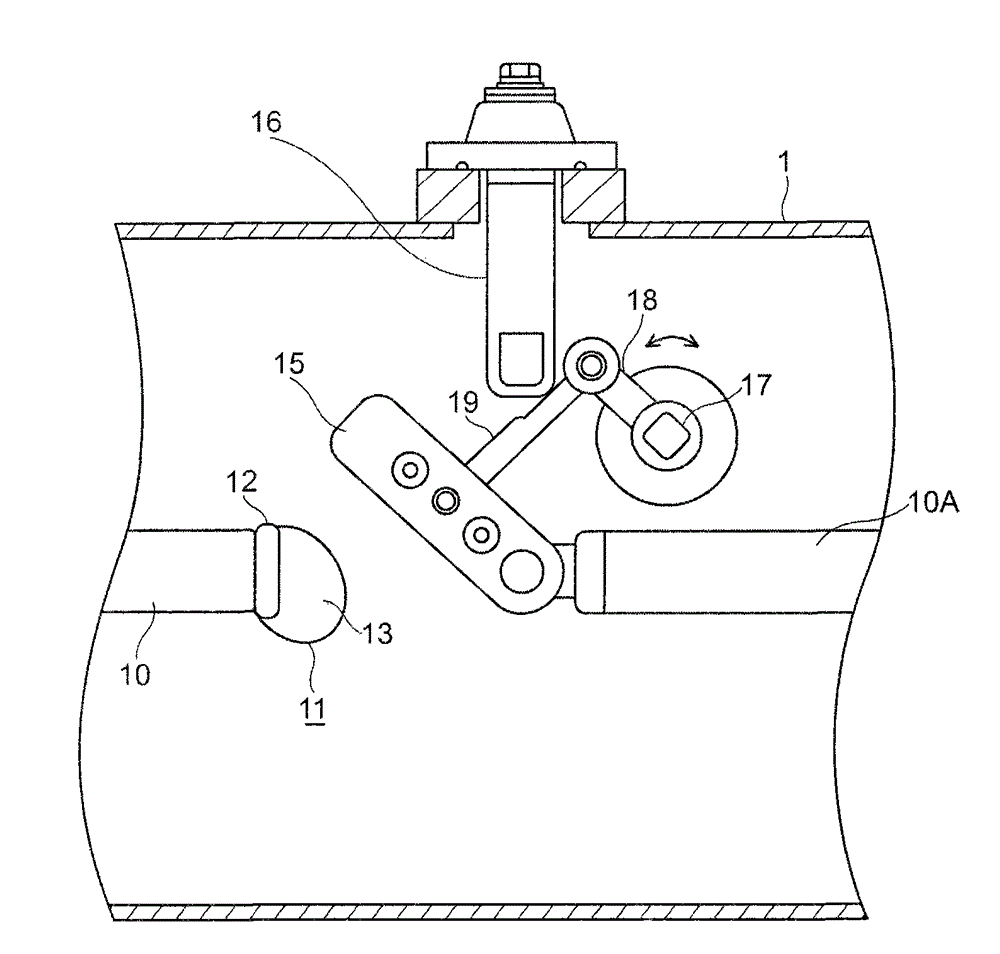

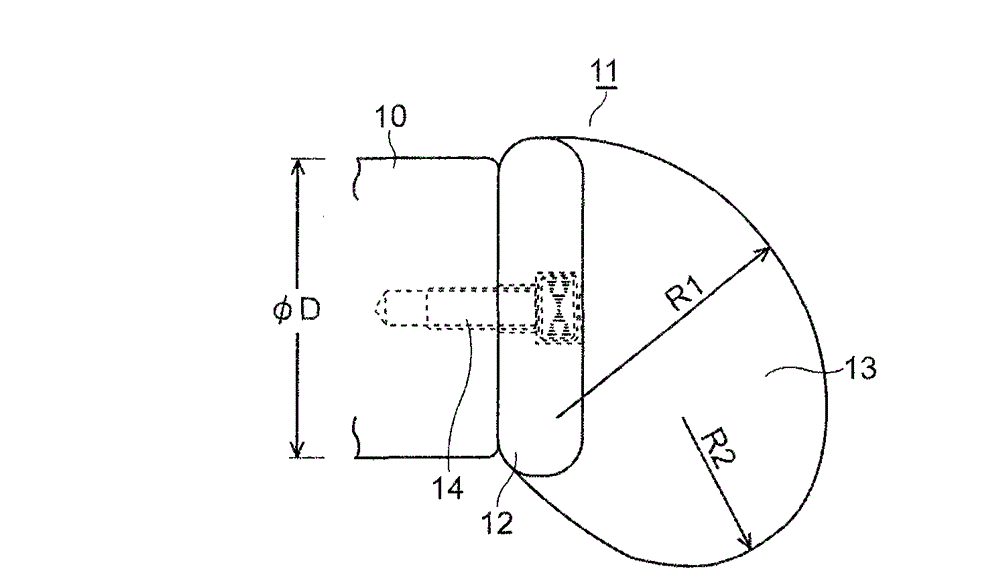

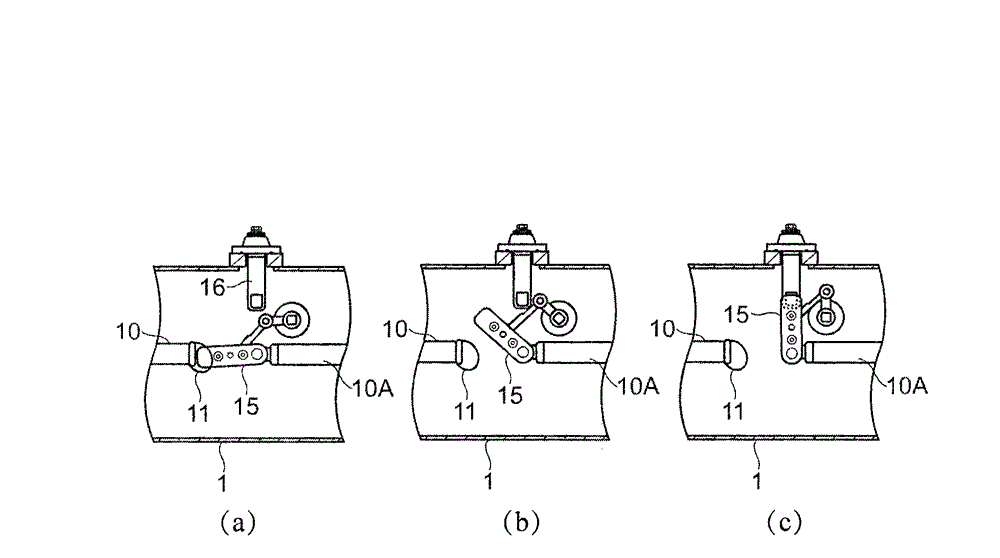

[0024] figure 1 The illustrated blade-shaped circuit breaker is arranged such that a pair of power transmission conductors 10 and 10A are arranged facing each other in a metal container 1 enclosed in an insulating gas or in the atmosphere. On the end surface of the one power transmission conductor 10, a fixed-side electrode 11 is provided, and the fixed-side electrode 11 passes through figure 2 Screws 14 etc. are shown to fasten the contact piece 12 with the flat electrical contact surface 13 . Furthermore, the movable vane 15 is provided on the end surface of the other power transmission conductor 10A so as to be foldable.

[0025] The movable vane 15 is connected by the rotary lever 18 fixed on the externally operated rotary shaft 17 and the operating rod 19, and is connected to and disconnected from the fixed side electrode 11 as the rotary shaft 17 rotates clockwise and counterclockwise. .

[0026] Also, inside the metal container 1, the ground side electrode 16 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com