Vehicular solar energy generating set

A power generation device and solar energy technology, applied in the direction of solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of high cost, no practical value, and unsuitable for popularization and application of vehicle-mounted power stations, and achieve convenient production and installation Erection, simple structure, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

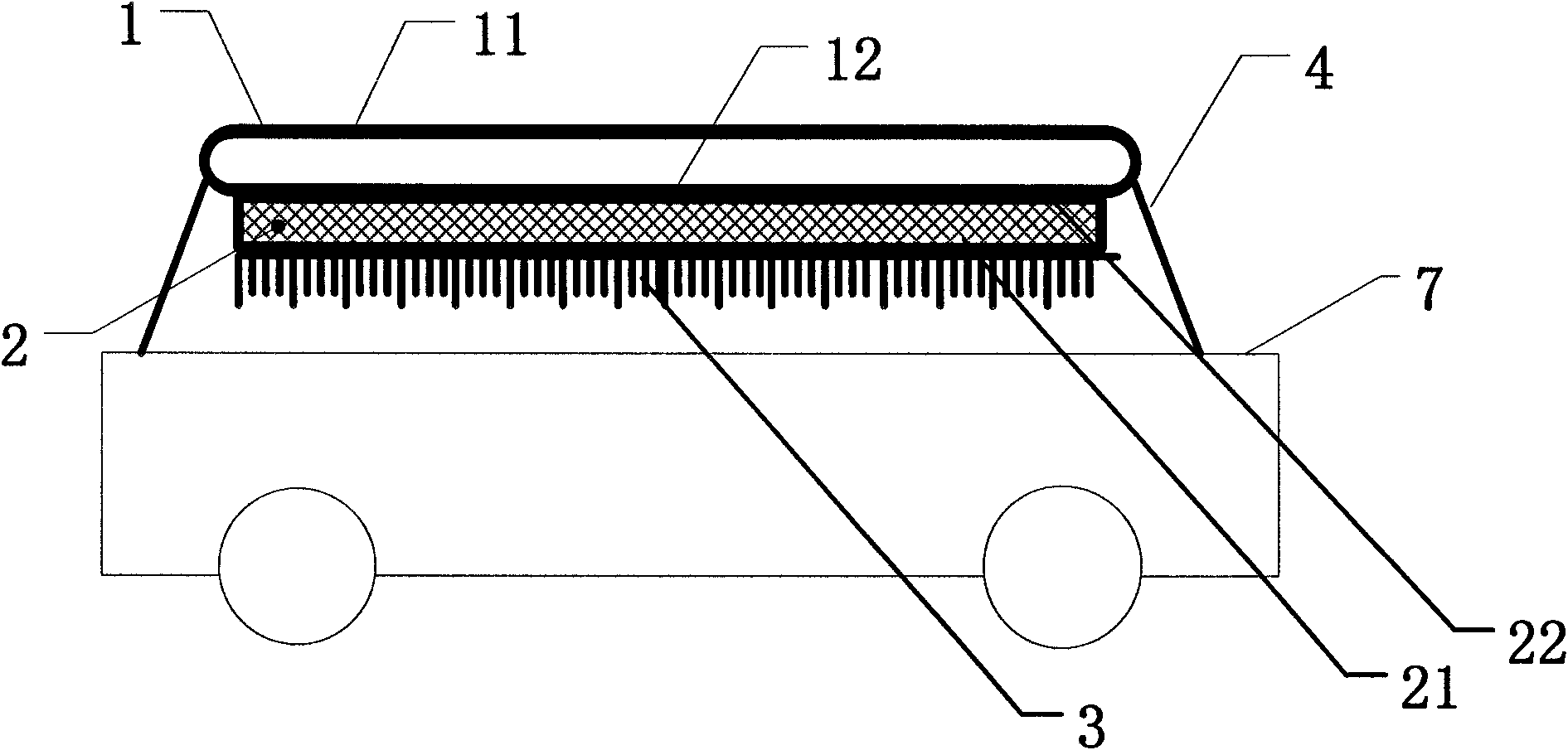

[0021] see figure 1 , the vehicle-mounted solar power generation device of the present invention includes a solar power generation assembly erected on the roof 7 by a support structure 4 fixed on the roof 7, and the solar power generation assembly includes: a solar heat collector 1 at the top, a thermoelectric cell 2 and heat sink 3.

[0022] The interior of the solar heat collector 1 is mainly composed of the upper glass 11 and the lower glass 12 to form a cylindrical vacuum space, forming a solar vacuum heat collection tube; the inner wall surface of the upper glass 11 is coated with a solar absorbing film.

[0023] The hot end 22 of the thermoelectric battery 2 is in contact with the solar heat collector 1 for heat exchange, and the cold end 21 of the thermoelectric battery 2 is in contact with the cooling fin 3 for heat exchange.

[0024] The cooling fin 3 is located at the bottom of the solar power generation module, and there is a cooling gap between the roof 7 and the ...

Embodiment 2

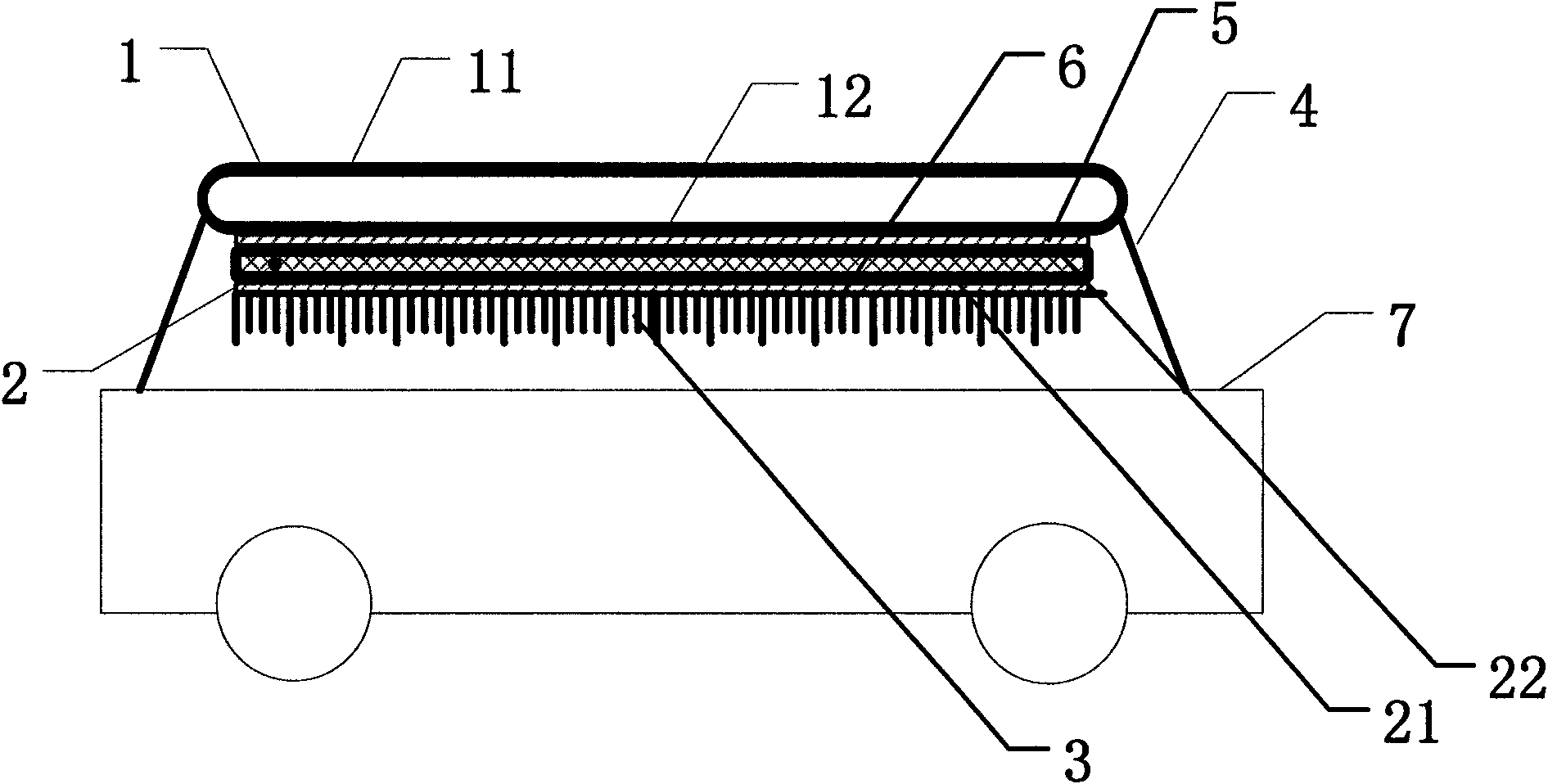

[0027] see figure 2 , in the vehicle-mounted solar power generation device of the present invention, a layer of heat-conducting silica gel 5 is coated between the hot end 22 of the thermoelectric battery 2 and the contact heat exchange part of the solar heat collector 1, and between the cold end 21 of the thermoelectric battery 2 and the heat sink 3 A layer of thermal silica gel 6 is coated between them. Other settings are the same as in Example 1.

[0028] When the device is working, the solar vacuum heat collecting tube converts direct sunlight, scattering and sunlight reflected by other reflective surfaces into heat, and transfers the heat to the hot end 22 of the thermoelectric battery 2 through the heat-conducting silica gel 5, so that the thermoelectric battery 2 starts to work and generates electric energy . In order to make the thermoelectric battery 2 work normally, there should be sufficient temperature difference between the hot end 22 and the cold end 21 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com