Formula feed of growing pigs and preparation method thereof

A technology of compound feed and growing pigs, which is applied in the field of feed, can solve the problems of full-price compound pellet feed patents and few literatures, and achieve the effects of low feed coefficient, high nutritional level, and high digestible energy value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

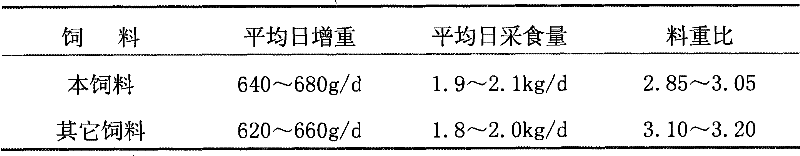

Examples

Embodiment 1

[0023] 1. First determine the production formula for growing pigs

[0024] According to the nutritional standards for growing pigs formulated by the company, the digestible energy of pigs is not less than 13.65MJ / Kg, crude protein is 18% to 19.5%, lysine is 1.05% to 1.3%, lysine: methionine and cystine: threonine Amino acid: tryptophan is 100:56:63:18, calcium 0.7%-0.8%, phosphorus 0.35%-0.7%. Calculating the optimum formula composition (being the best embodiment of the present invention) is:

[0025] Corn: 57.44%, imported fish meal: 1.5%, soybean meal: 22%, puffed soybean: 5%, secondary flour: 5%, rice skin: 3%, rice bran: 3%, soybean oil: 1.5%, sweetener: 0.03 %, compound enzyme preparation: 0.03%, 811 compound premix: 1.5%. 811 is a model of compound premix, which can be purchased directly in the market. The fish meal is imported fish meal, and the nutritional content can be guaranteed.

[0026] 2. All the equipment used for preparation is outsourced, and the steps are ...

Embodiment 2

[0038] The mass percentage of each component is: corn: 64.12%, fish meal: 0.2%, soybean meal: 20.3%, puffed soybean: 3%, secondary flour: 2%, rice skin: 2%, rice bran: 4.5%, soybean oil: 1.1% , sweetener: 0.04%, compound enzyme preparation: 0.04%, compound premix: 1.9%. low cost.

Embodiment 3

[0040] The mass percentage of each component is: corn: 50.7%, fish meal: 1.5%, soybean meal: 24.7%, puffed soybean: 5%, secondary flour: 5%, rice skin: 5%, rice bran: 5%, soybean oil: 1% , sweetener: 0.05%, compound enzyme preparation: 0.05%, compound premix: 1.5%. The nutritional level is high and the growing pigs grow fast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com