Method for producing compound belt blank by cold feed wide rubber sheet extrusion calendaring linkage production line

A production method and cold-feeding technology, which is applied in the field of compound strip blanks in the cold-feeding wide-width film extrusion and calendering linkage production line, can solve the problem of the transformation of the IW steel curtain mesh calendering unwinding guide uncoiling device and the difficulty in maintaining the weft cord Straight and square, adhesive rate and thickness are difficult to control, etc., to achieve the effect of high density, low porosity and stable spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

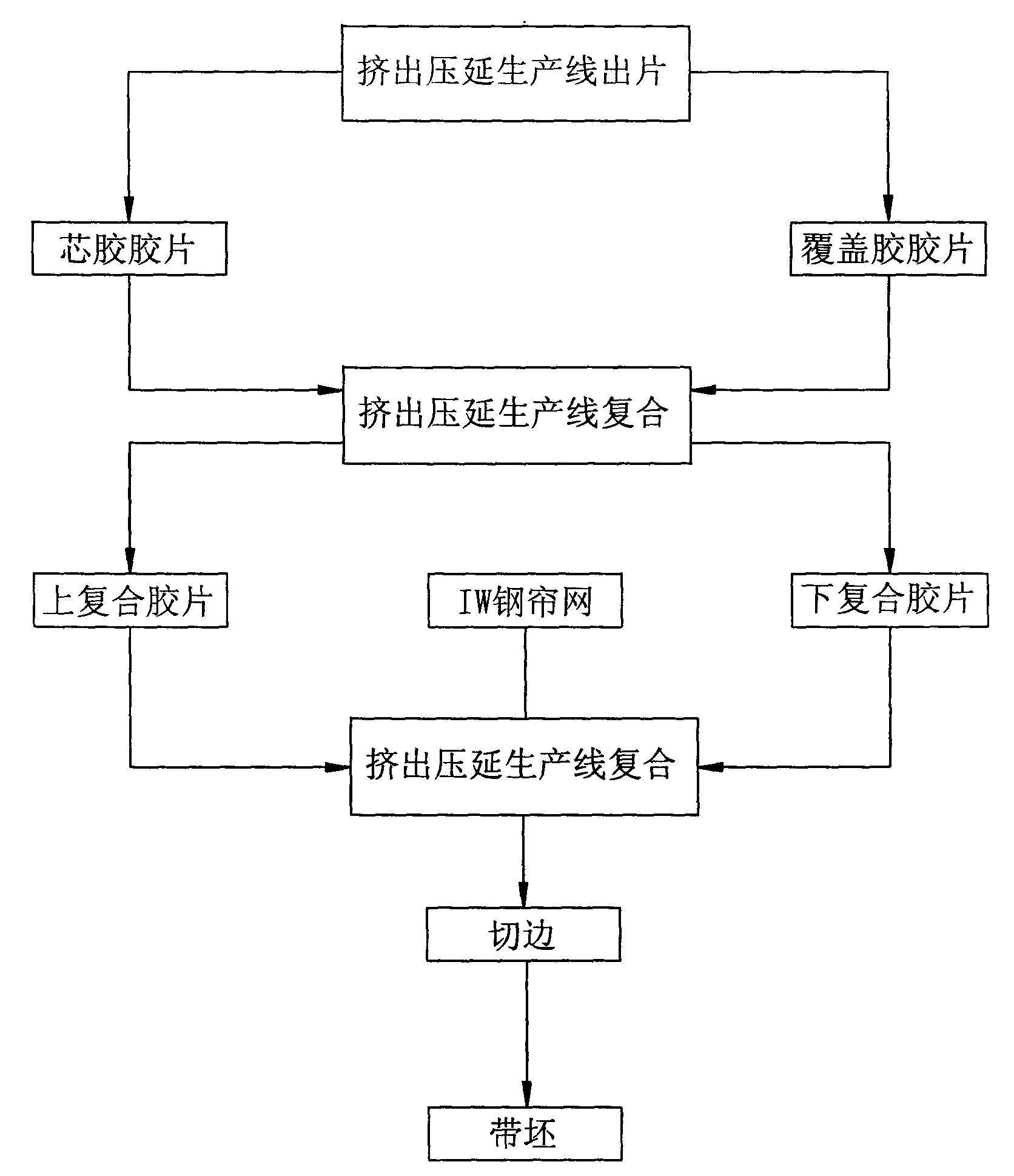

[0028] Embodiment 1: The present invention mainly adopts the production method of compounding blanks in the extrusion and calendering production line of cold-feed wide-width film. The strip blank is completed on the film extrusion and calendering linkage production line. Including the following process steps:

[0029] 1. Core glue and cover glue out

[0030] The mixed rubber of the core rubber and the mixed rubber of the cover rubber are respectively extruded by a cold-feed wide-width film extruder and calendered by a two-roller calender to make a core rubber film and a cover rubber film. The core rubber film and the cover rubber film are separated by pad cloth and taken up without tension. The roller deflection compensation of the two-roller calender adopts the cross-axis adjustment to eliminate the waist drum shape of the film section, which is thick in the middle and thin on both sides.

[0031] Cold feed extruder extrusion, two-roll calender calender process parameters:...

Embodiment 2

[0051] Embodiment 2: The present invention mainly adopts the production method of compounding blanks in the extrusion and calendering production line of cold-feed wide-width film. The strip blank is completed on the film extrusion and calendering linkage production line. Including the following process steps:

[0052] 1. Core glue and cover glue out

[0053] The mixed rubber of the core rubber and the mixed rubber of the cover rubber are respectively extruded by a cold-feed wide-width film extruder and calendered by a two-roller calender to make a core rubber film and a cover rubber film. The core rubber film and the cover rubber film are separated by pad cloth and taken up without tension. The roller deflection compensation of the two-roller calender adopts the cross-axis adjustment to eliminate the waist drum shape of the film section, which is thick in the middle and thin on both sides.

[0054] Cold feed extruder extrusion, two-roll calender calender process parameters:...

Embodiment 3

[0074] Embodiment 3: The present invention mainly adopts the production method of compounding blanks in the extrusion and calendering production line of cold-feed wide-width film. The strip blank is completed on the film extrusion and calendering linkage production line. Including the following process steps:

[0075] 1. Core glue and cover glue out

[0076] The mixed rubber of the core rubber and the mixed rubber of the cover rubber are respectively extruded by a cold-feed wide-width film extruder and calendered by a two-roller calender to make a core rubber film and a cover rubber film. The core rubber film and the cover rubber film are separated by pad cloth and taken up without tension. The roller deflection compensation of the two-roller calender adopts the cross-axis adjustment to eliminate the waist drum shape of the film section, which is thick in the middle and thin on both sides.

[0077] Cold feed extruder extrusion, two-roll calender calender process parameters:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com