Dope for automotive trim plastic parts and preparation method thereof

A technology for automotive interiors and plastic parts, applied in the direction of coating, etc., can solve the problems of environmental protection and poor medium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Clean the paint mixing tank, weigh 50 parts of hydroxyacrylic resin, 0.15 parts of polymer dispersant, and 12 parts of 100# solvent, mix them into the paint mixing tank, stir at a low speed to fully dissolve, and stir for 30 minutes; weigh 2.6 parts of carbon black and 5 parts of SNM-100 wear-resistant powder are added to the paint mixing tank under stirring, the number of revolutions of stirring is 800 rpm, and the stirring time is 30 minutes; grind the prepared slurry above with a sand mill, until the fineness is qualified; weigh 5 parts of chlorinated polypropylene resin, 0.2 parts of silicone leveling agent, and 3 parts of CAC, and add them to the paint mixing tank under the condition of stirring. The time is 30 minutes; finally weigh 24.8 parts of butyl acetate, add it to the paint mixing tank, adjust the viscosity to pass, stir for 20 minutes, filter with 200 mesh filter cloth, and pack.

Embodiment 2~3

[0022] According to the proportion of materials described in Table 2, the method described in Example 1 is used to produce the coating for automotive interior plastic parts, and the performance of some items of the product obtained is shown in Table 3.

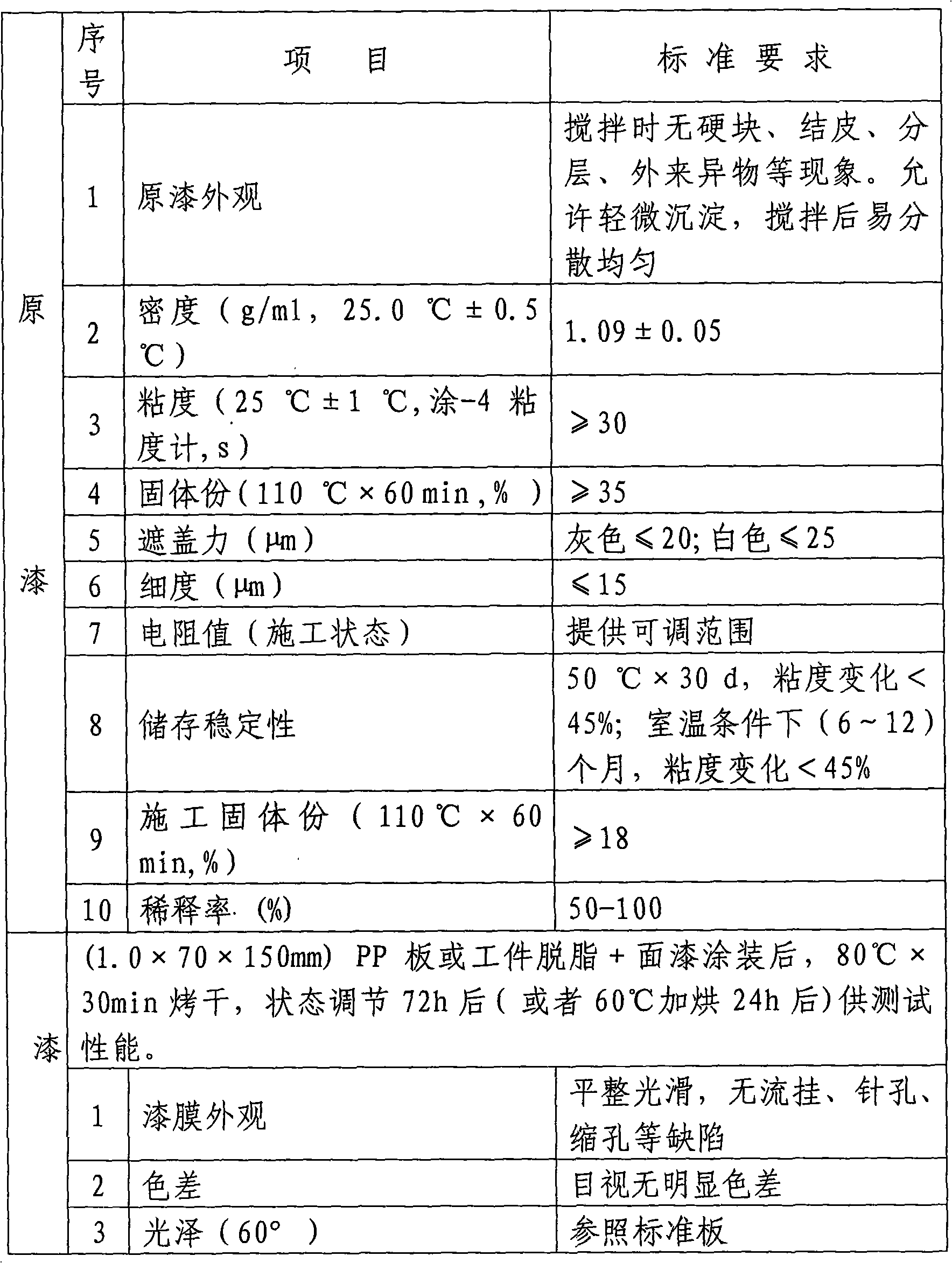

[0023] Table 1: The performance index of the coating prepared according to the weight ratio stated in the formula

[0024]

[0025]

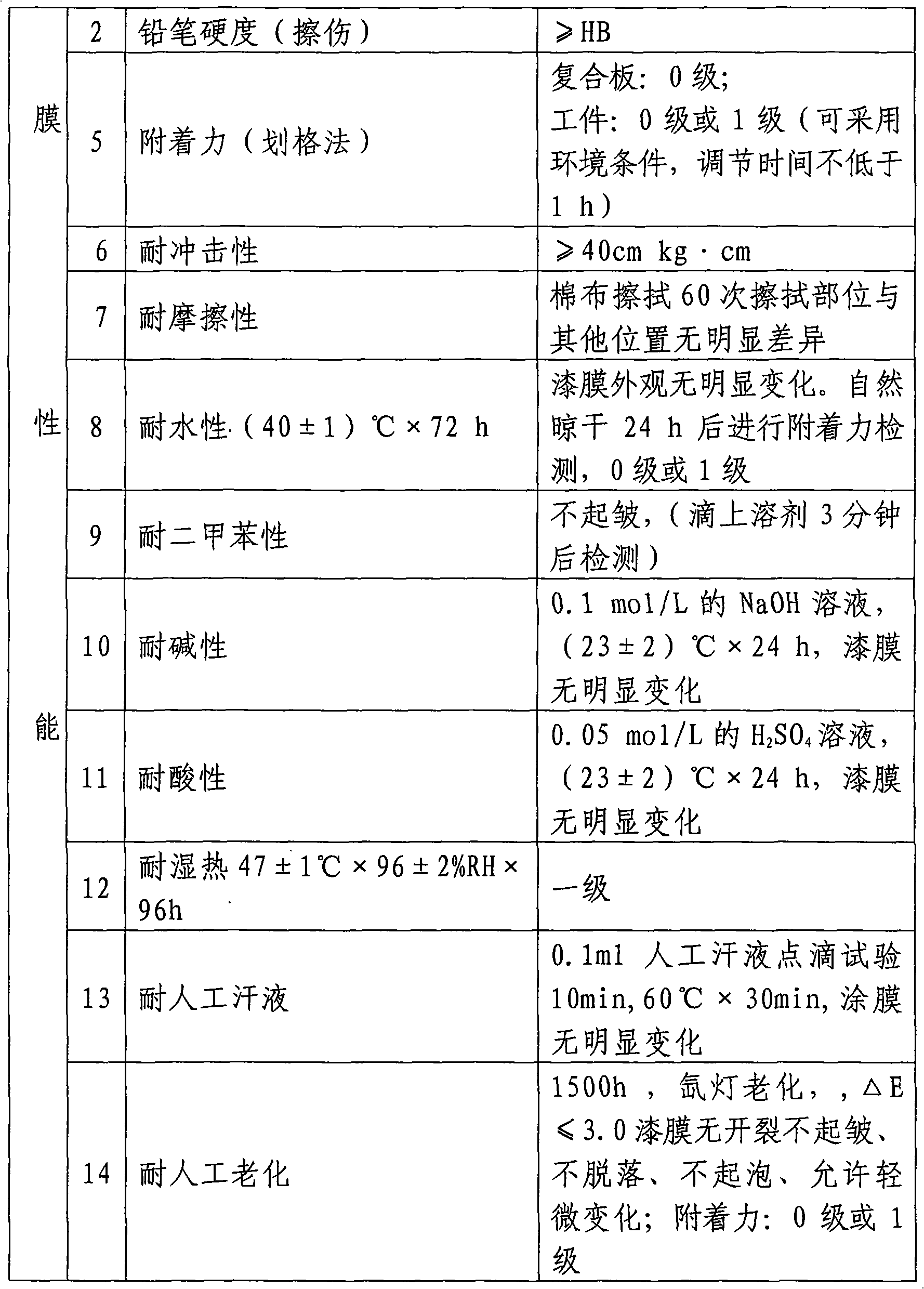

[0026] Table 2: each component formula of embodiment 1-3

[0027]

[0028]

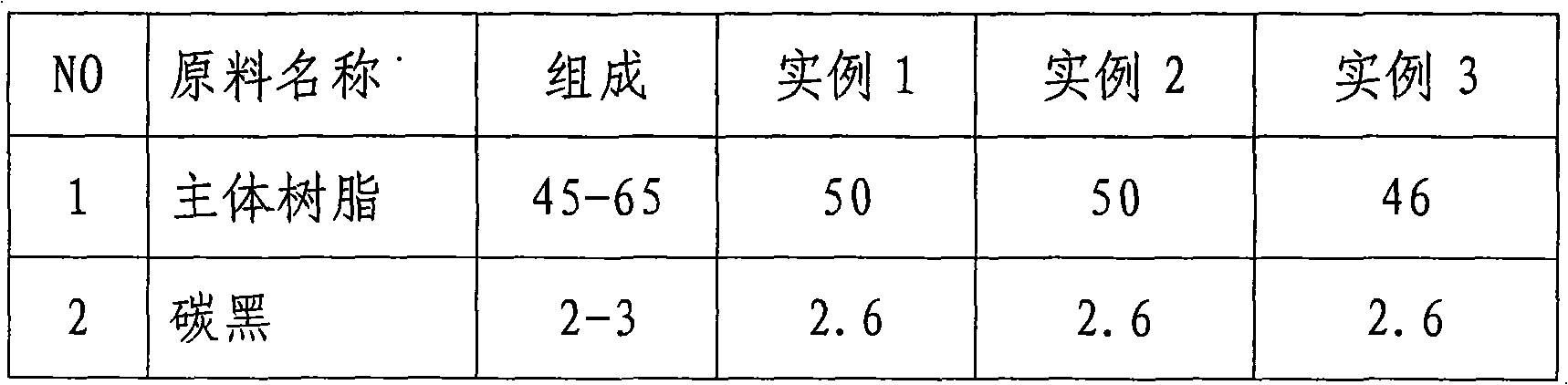

[0029] Table 3: Test results of some items of each embodiment

[0030] NO

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com