Porous floating breakwater formed by splicing prefabricated components

A technology of prefabricated components and breakwaters, which is applied in the directions of breakwaters, jetties, embankments, etc., can solve the problems of difficulty in controlling the amount of movement and poor wave-absorbing effect, and achieve the effect of convenient construction, good wave-absorbing effect and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Determine the width of the main structure 11 and its connection mode with the seabed (pile foundation anchoring, anchor chain or tension cable 14 anchoring) according to the water depth, geology and wave conditions of the actual application sea area, and then determine the size, quality and hollowness of each prefabricated component. Spend.

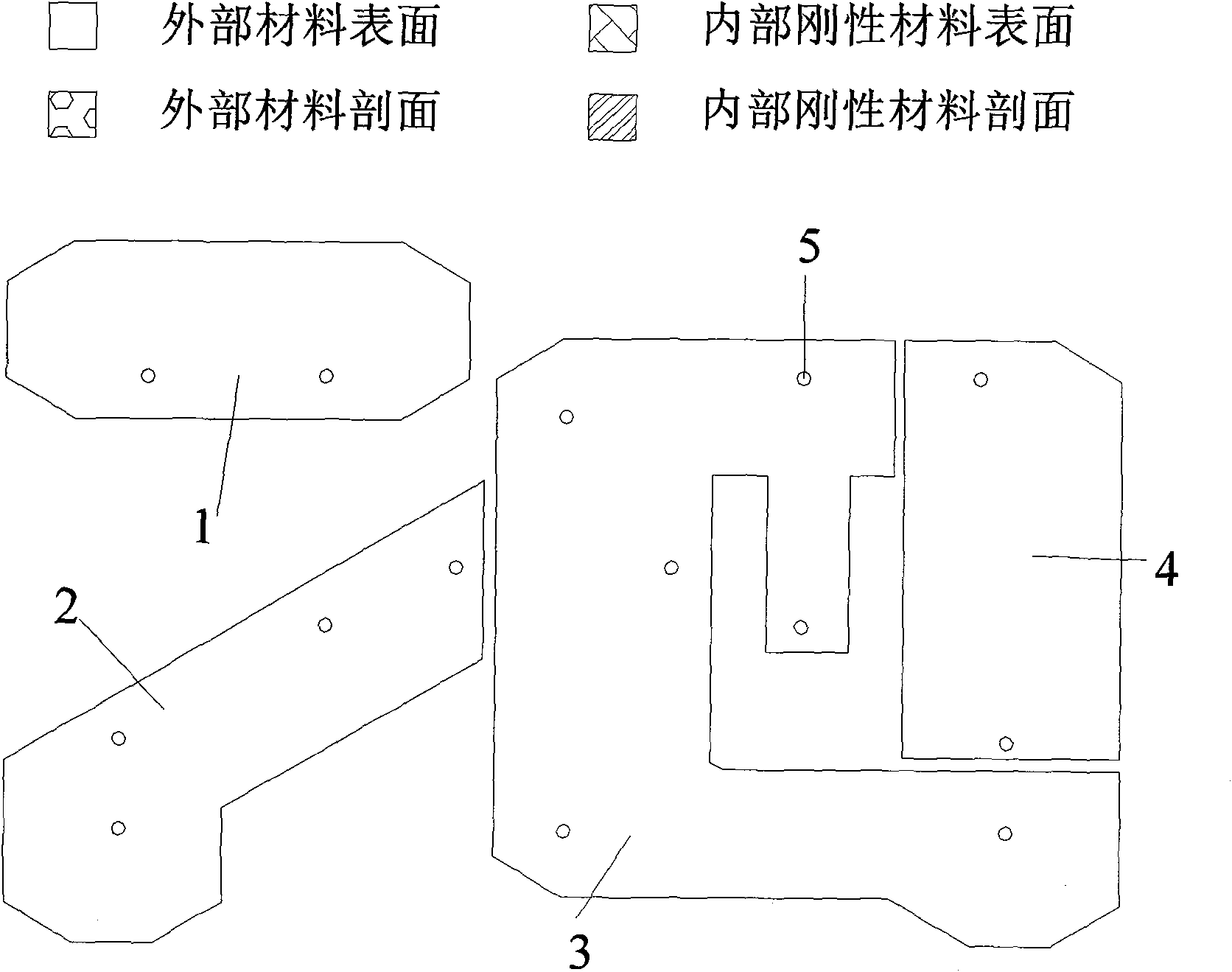

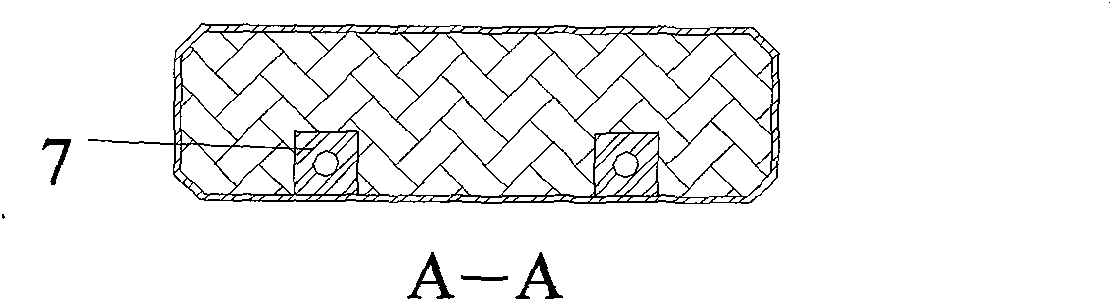

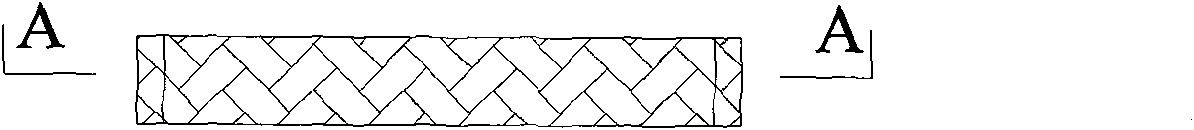

[0026] Take the prefabricated component 9 as an example, there are two penetrating circular holes 5 on it, and due to the existence of the rigid block 7, the circular holes 5 will not affect the sealing performance of the internal rigid closed box 6 of the prefabricated component 1. The prefabricated component 1 has an internal rigid closed box 6 wrapped with an external material 8 , and the external material 8 is made in the form of a multi-rhombic staggered arrangement, so that the surface of the prefabricated component 9 has grooves 16 . The outer contour 1 of the prefabricated component is the outline drawing of the prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com