Inverted construction method for template engineering of cast-in-place shear wall structure system

A formwork engineering and construction method technology, applied in the direction of building structure, construction, etc., can solve the problems of large safety hazards, time-consuming and labor-consuming, formwork axis position and verticality deviation, etc., to achieve cost saving, obvious economic benefits, and improvement quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

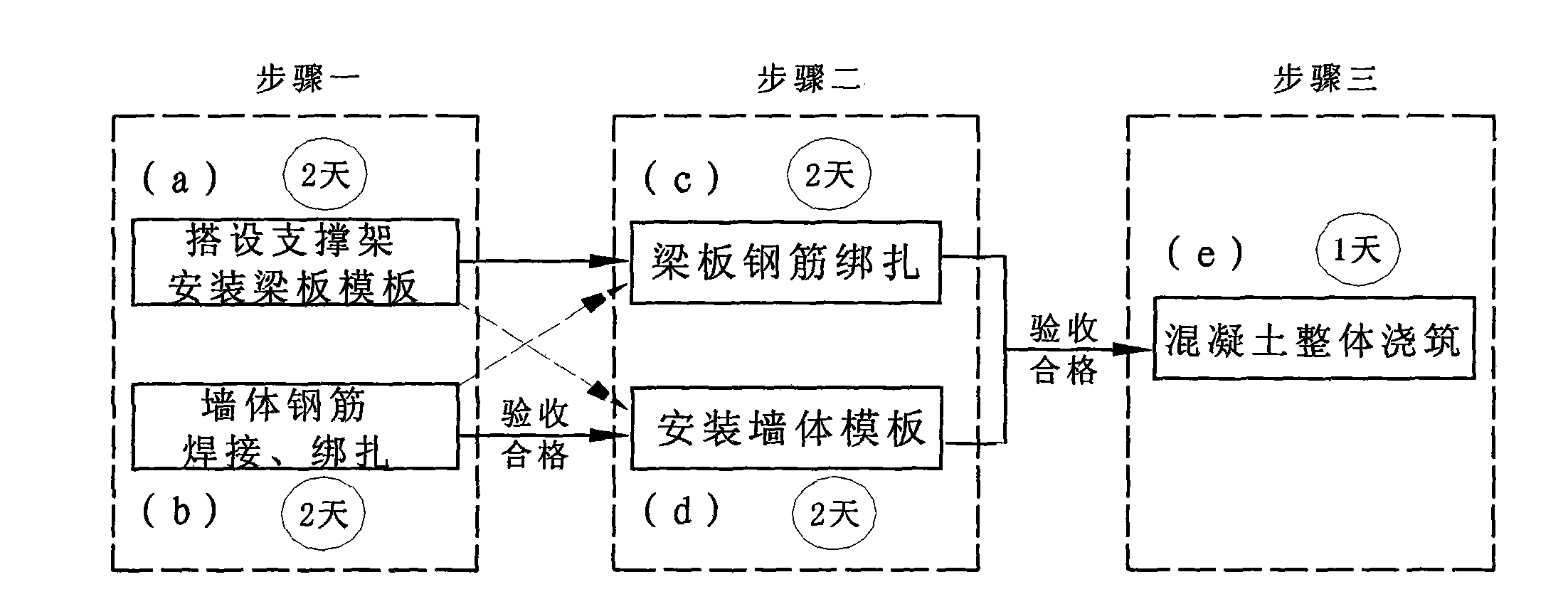

[0052] see figure 1 , the reverse order construction method of the formwork engineering of the cast-in-place shear wall structure system includes the following steps:

[0053] (1) Step 1:

[0054] This step includes the (a) process that is carried out simultaneously: erecting the support frame 3, installing the beam slab formwork 1 and (b) process: welding and binding the wall reinforcement 4;

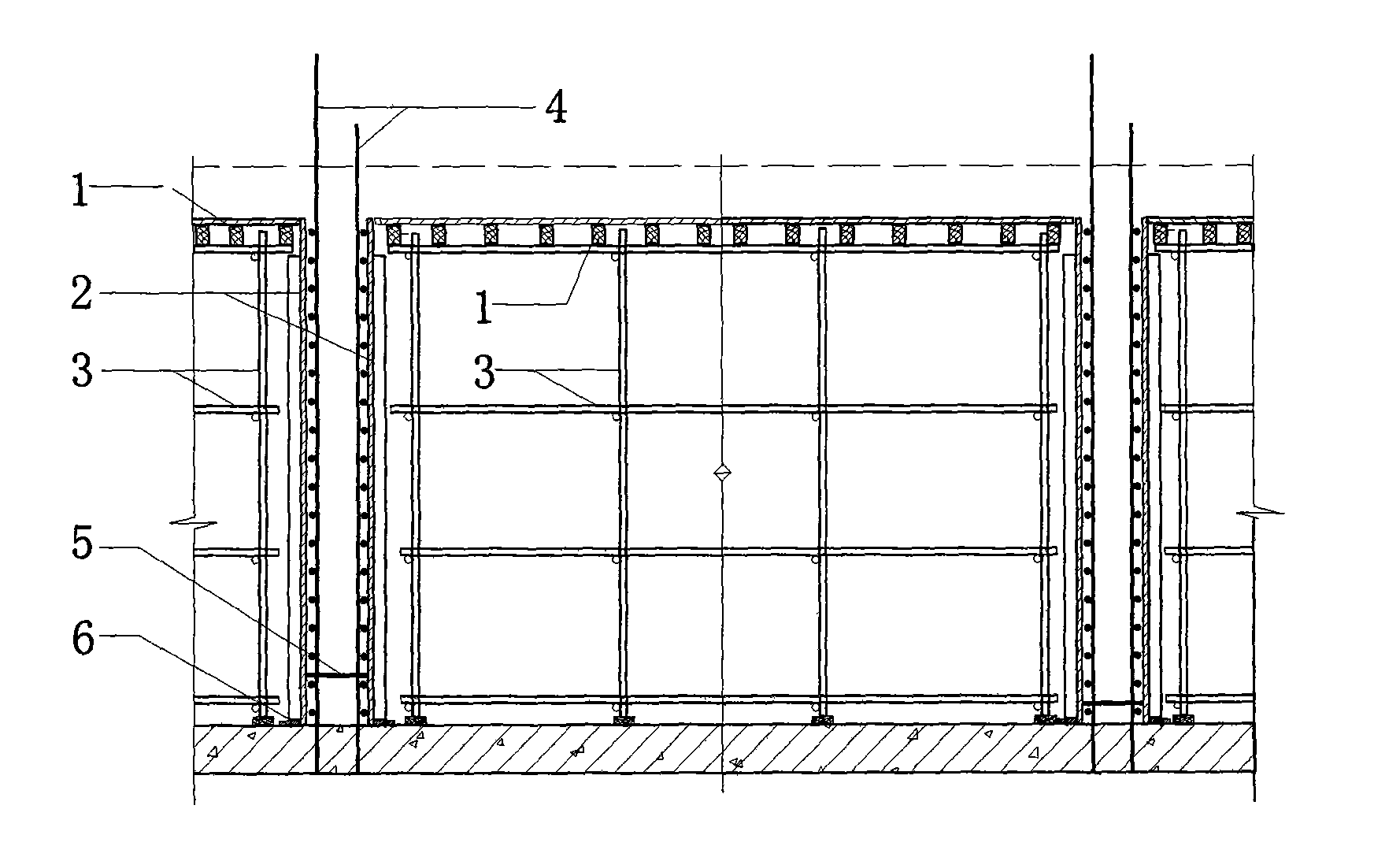

[0055] (a) Process: set up support frame, install beam and slab formwork

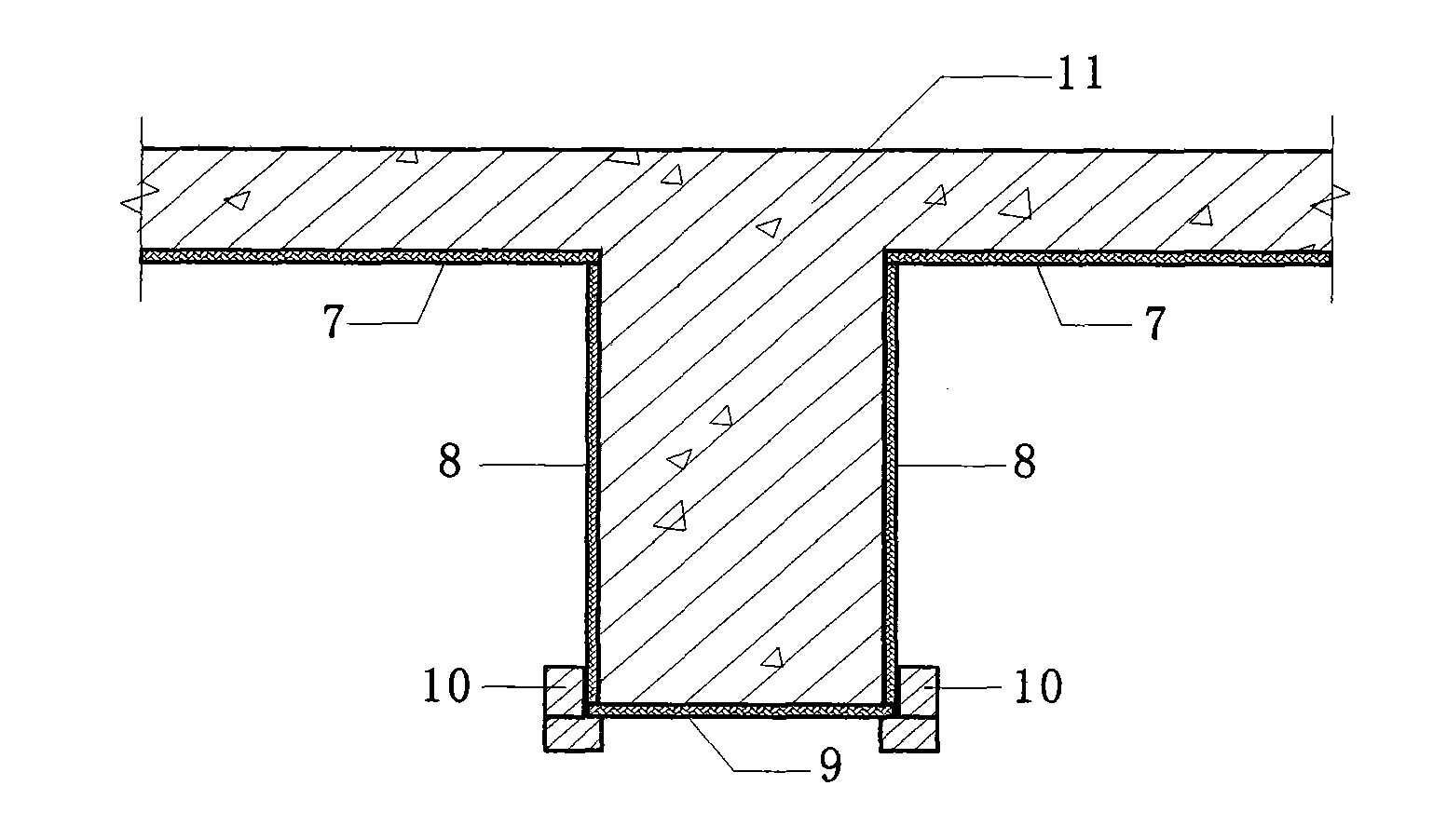

[0056] When there is a working surface on the construction floor, the erection work of the supporting frame 3 can be started. After the whole hall support frame 3 is erected, the beam slab formwork 1 is laid. Beam slab formwork 1 adopts the method that beam side formwork 8 wraps beam bottom formwork 9, see image 3 , that is, the beam side formwork 8 clamps the beam bottom formwork 9, and the lower part of the beam bottom formwork 9 is provided with a stiffening square timber 10 to support the beam side for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com