Inner thermal storage solar low-temperature thermal power generation system

A power generation system and solar energy technology, applied in the field of solar power generation, can solve the problems of large average heat transfer temperature difference of the heat exchange medium of the heat collector and high average operating temperature of the heat collector, so as to prolong the time for storing or releasing heat, reduce Heat transfer temperature difference and the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

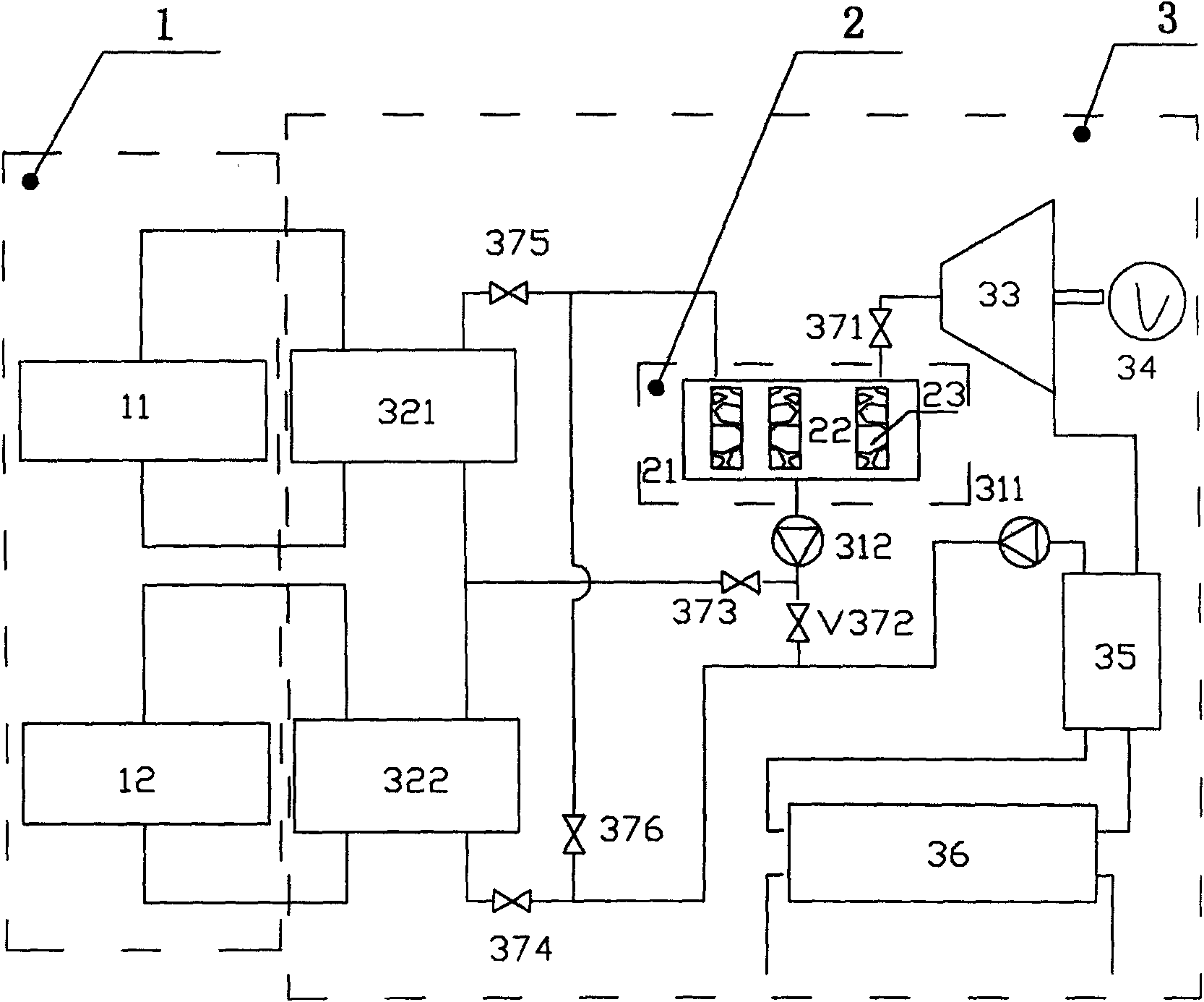

[0027] see figure 1 and figure 2 , the internal heat storage solar low temperature thermal power generation system includes a compound parabolic collector system, a heat storage system, and an organic Rankine cycle power generation system;

[0028] The compound parabolic heat collector system includes a compound parabolic heat collector array 11 at the high temperature end and a compound parabolic heat collector array 12 at the low temperature end;

[0029]The organic Rankine cycle power generation system includes an evaporator, a steam turbine 33, a generator 34, a regenerator 35, a condenser 36, two pumps and six valves; wherein the output end of the steam turbine 33 is connected to the generator 34, and the exhaust of the steam turbine 33 The gas port is connected to the regenerator 35, and the other port of the regenerator 35 is connected to the condenser 36. The port is connected to the liquid storage tank 21 through the valve 376, and connected to the liquid zone evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com