Turbine vane type of starting torque converter for hydraulic drive locomotive

A technology of hydraulic transmission and torque converter, applied in the field of hydraulic transmission locomotives, can solve the problems of low efficiency, inconspicuous blade streamline, uneven flow channel area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

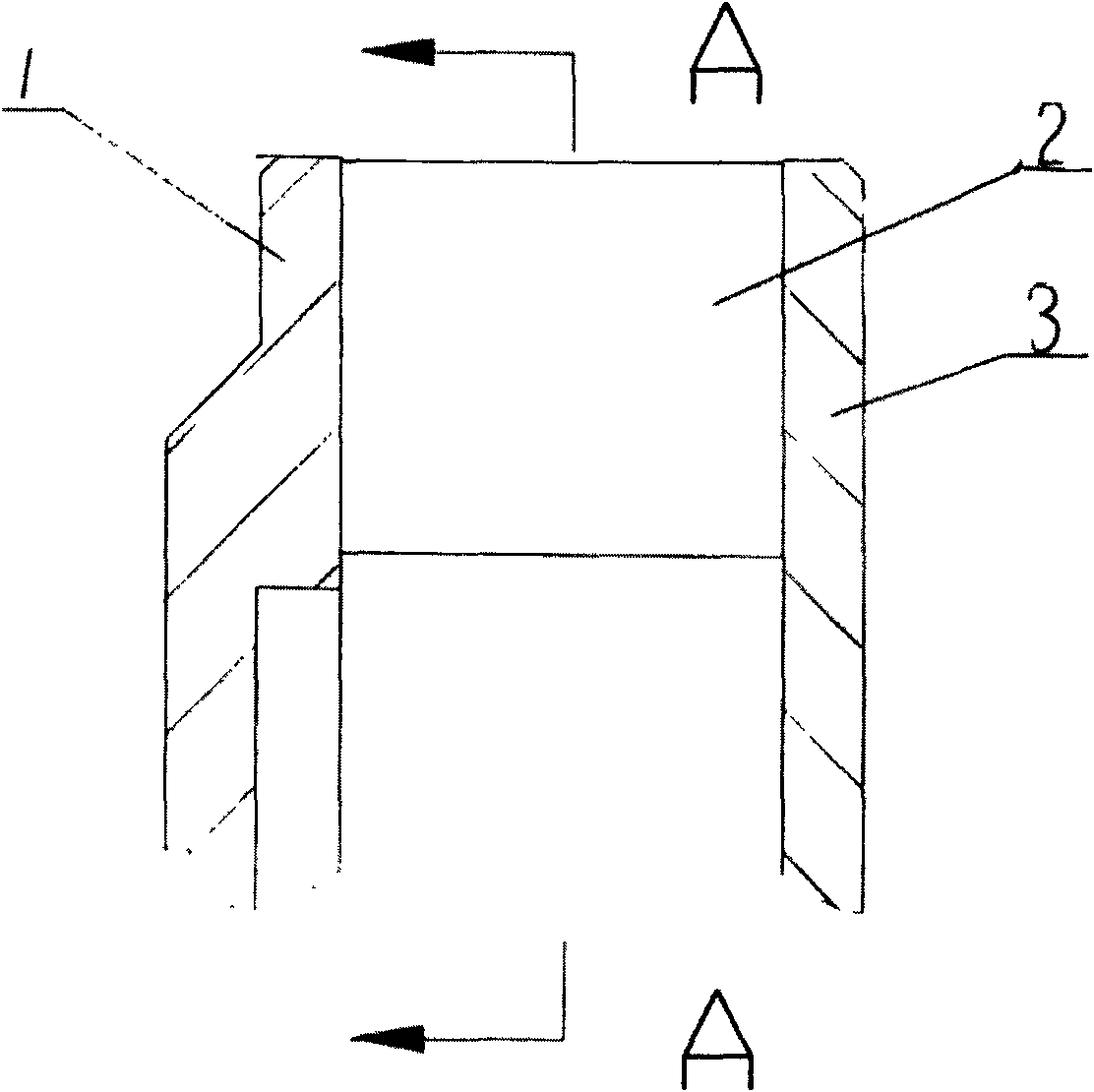

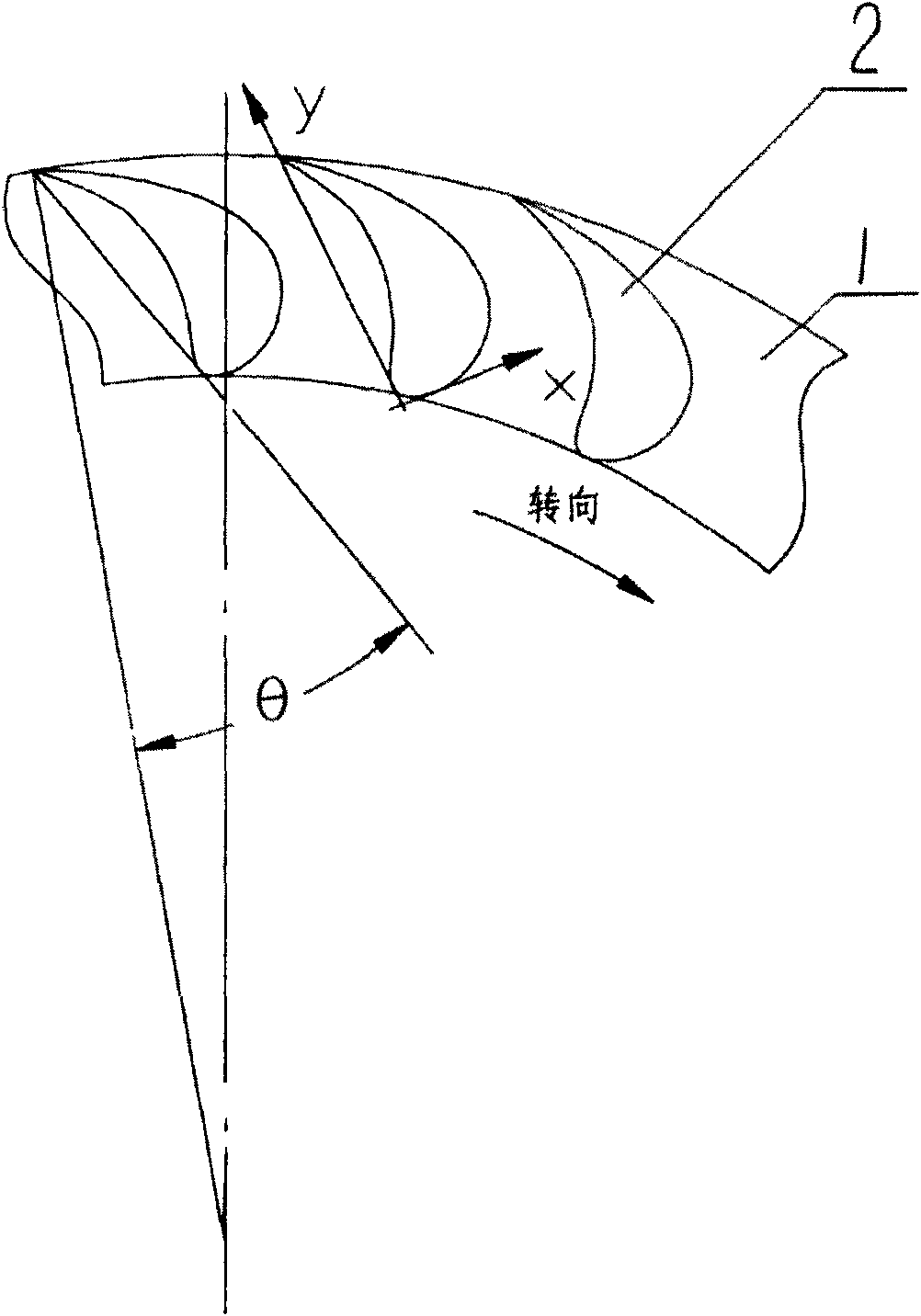

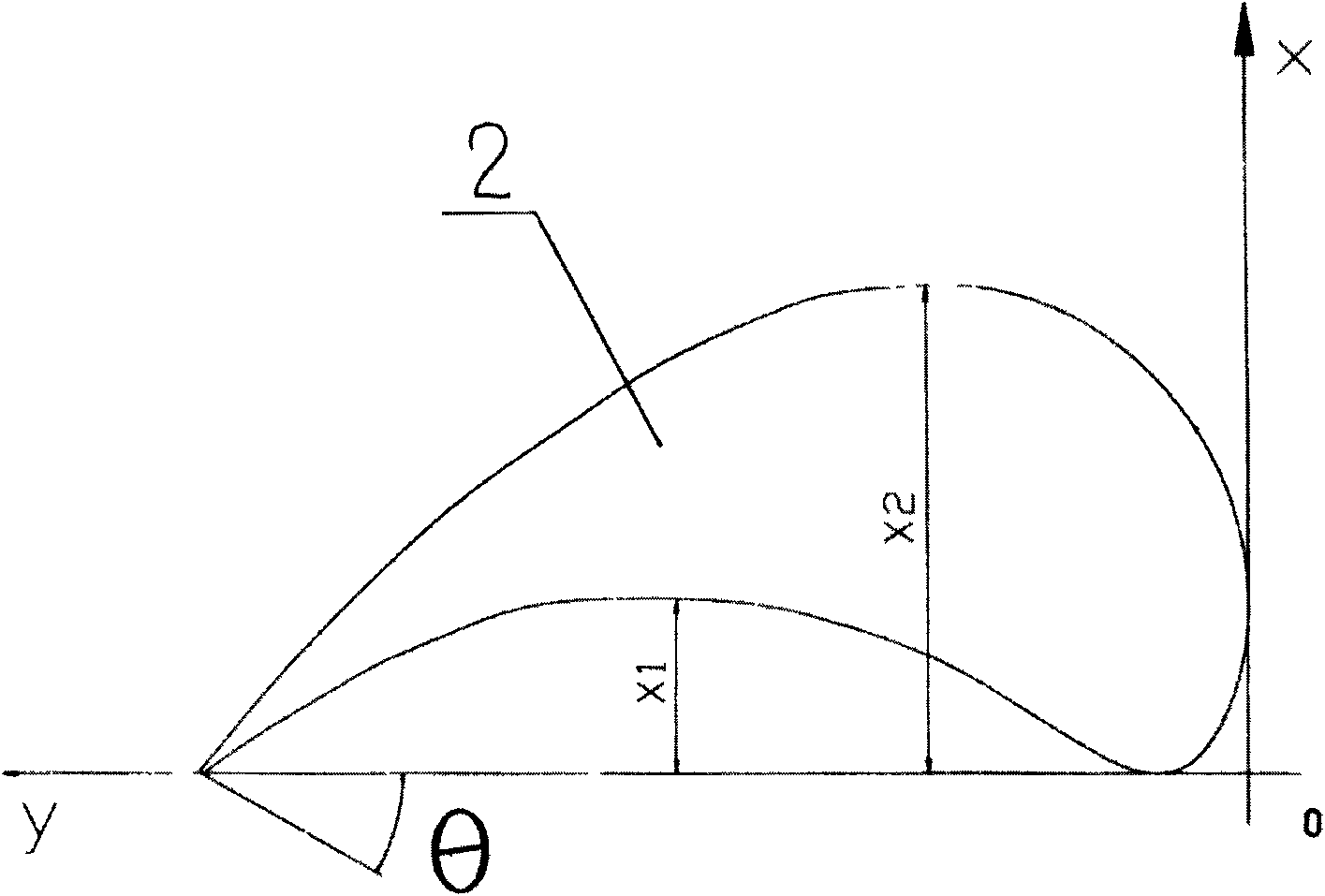

[0019] exist figure 1 , figure 2 and image 3 In the schematic diagram of the turbine blade profile of the starting torque converter for a hydraulic transmission locomotive shown, the turbine has two annular disks opposite and parallel to the turbine disks 1 and 2, and several blades are vertically fixed between the two annular disks. 3. They form cascades. These blades with the same structure and regularly arranged are all cylindrical shells with a leaf-like cross section. The front ends of these blades are all arranged on the inner diameter circle of the annular disk surface of the turbine disk, and the rear ends of these blades are all arranged on the outer diameter circle of the annular disk surface of the turbine disk. In the section of the above-mentioned blade, the two arc-shaped connecting lines from the front end to the rear end are different curves. The shape of the above-mentioned blades and the distance between the inner and outer sides can be expressed by a r...

example 2

[0025] Its structure is basically the same as Example 1, except that

[0026]

[0027]

[0028] Y value

[0029] Y value

[0030] The included angle θ between the line connecting the front end and the rear end of the blade of the present invention and the line connecting the center of the turbine disk and the rear end of the blade is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com