Permanent magnetic ferrite sintering electric kiln

A permanent magnet ferrite and electric kiln technology, applied in the field of kilns, can solve the problems of being easily burnt out and scrapped, product loss, etc., and achieve the advantages of improving the qualification rate and temperature control sensitivity, increasing product volume, and reducing production energy consumption. Effect

Inactive Publication Date: 2011-01-05

四川川西磁业有限责任公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the one hand, the heating element is easily burnt and scrapped when it generates an arc; on the other hand, because the temperature of the heating element is extremely high when the arc is generated, the product dropped on it is scrapped and causes losses

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

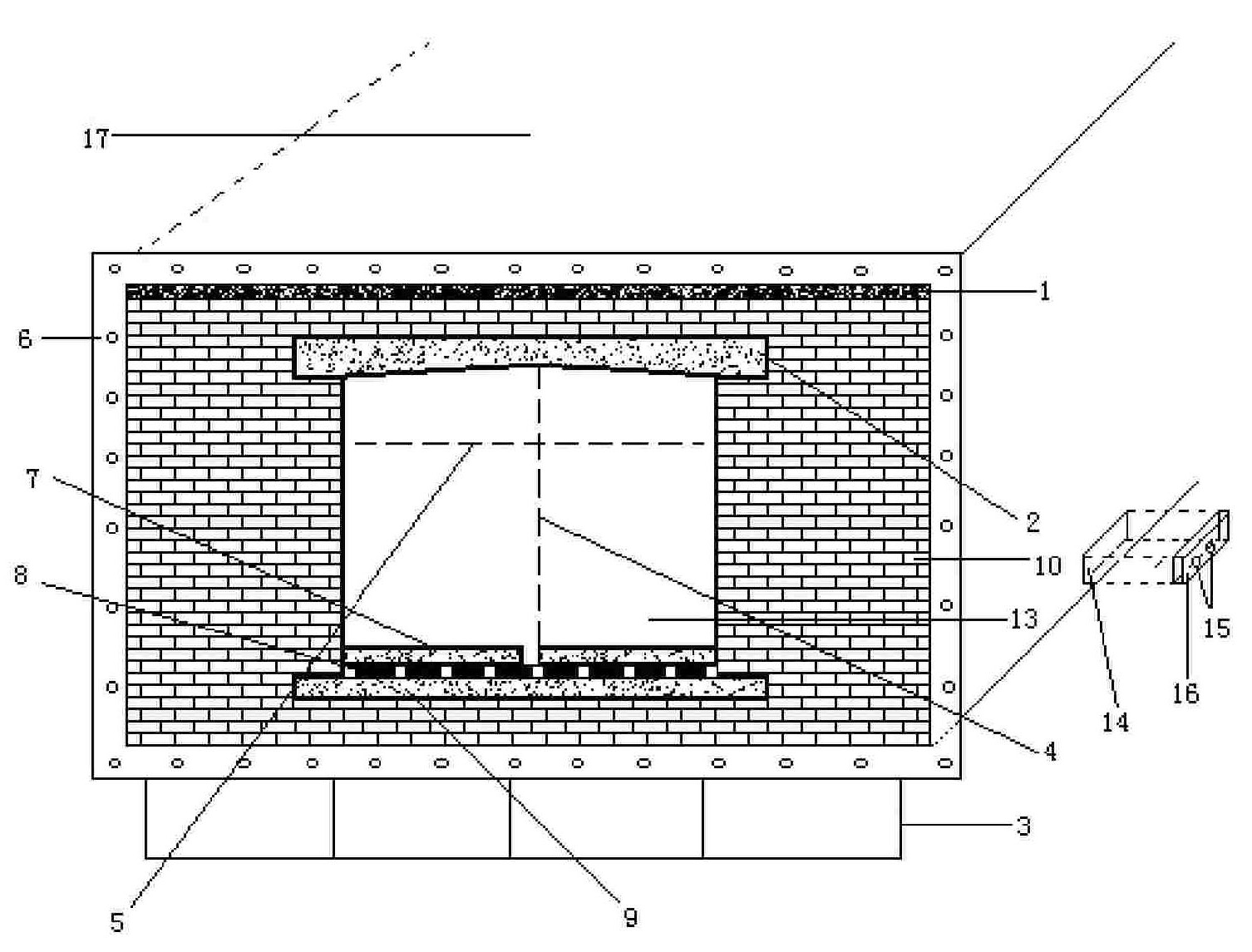

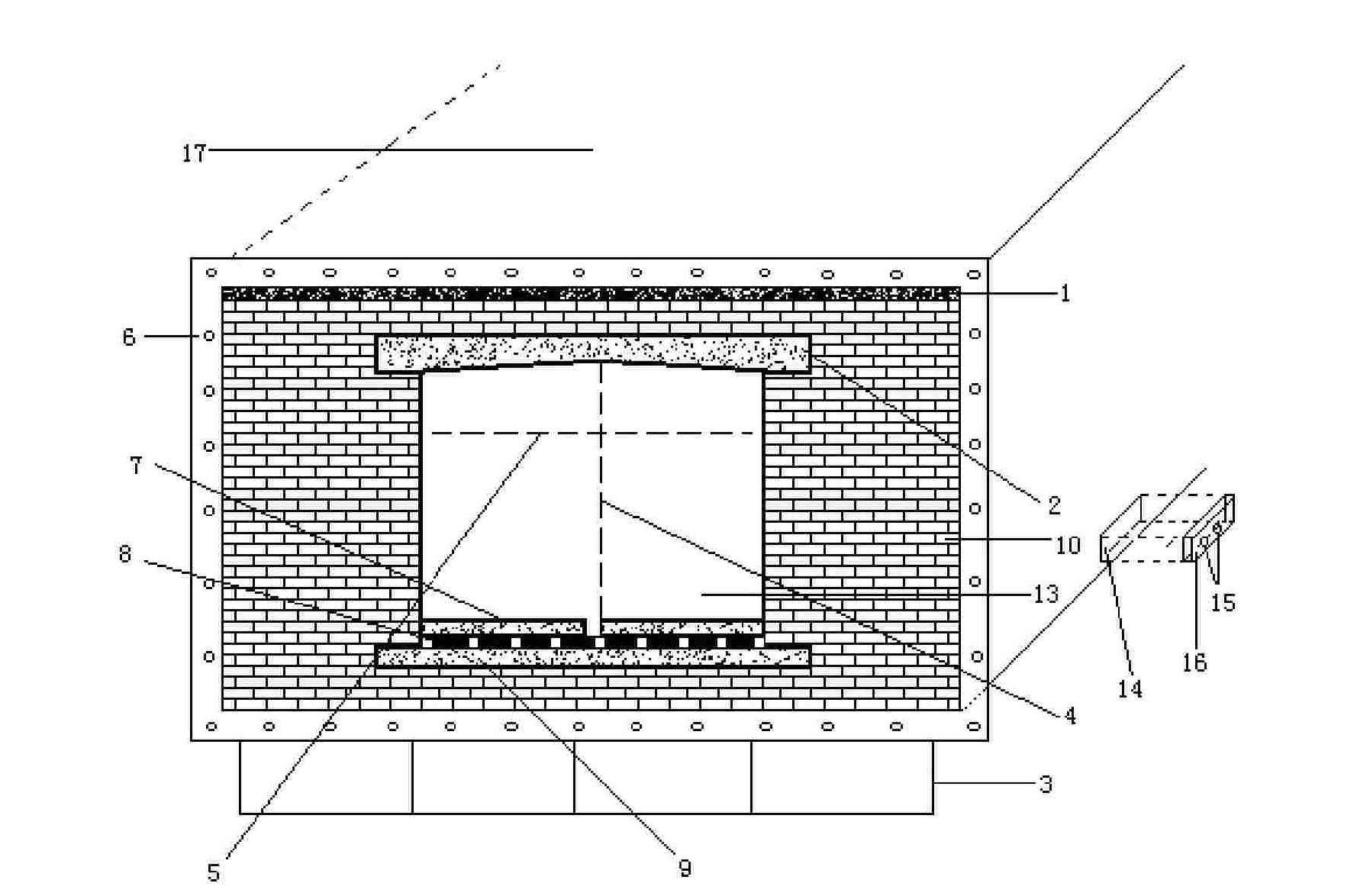

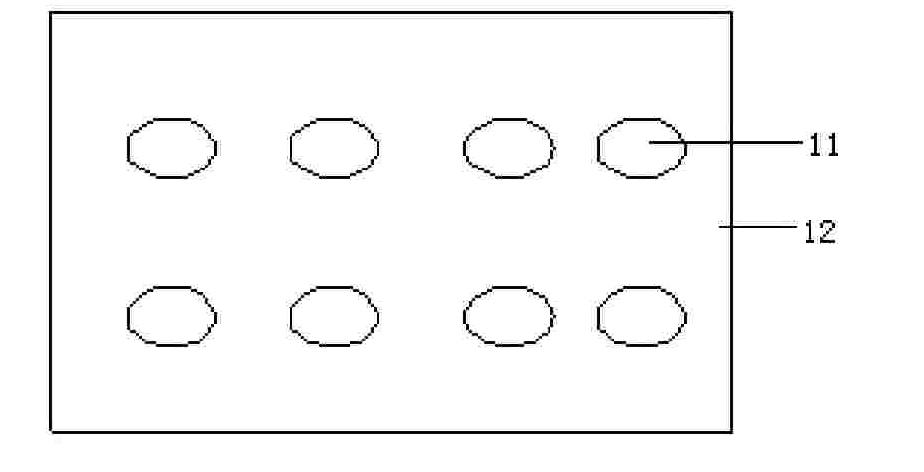

The invention relates to a permanent magnetic ferrite sintering electric kiln and belongs to the field of kilns. The invention solves a technical problem of providing a permanent magnetic ferrite sintering electric kiln capable of cleaning products falling onto a heating element in time. The permanent magnetic ferrite sintering electric kiln of the invention comprises a kiln body, wherein the kiln body comprises a kiln wall and a furnace chamber enclosed by the kiln wall; and a sundries discharge channel is arranged below the furnace chamber. The permanent magnetic ferrite sintering electric kiln of the invention can clean the products falling onto the heating element in time, avoid the scrapping of the heating element and the products falling onto the heating element, improve the productquality at each time of sintering, reduce product sintering cost, improve product qualification rate and temperature control flexibility, improve the thermal insulation effect of the furnace chamber and reduce production cost.

Description

Electric kiln for permanent magnet ferrite sintering technical field The invention relates to an electric kiln for sintering permanent magnet ferrite, belonging to the field of kilns. Background technique The electric kiln for permanent magnet ferrite sintering mainly includes several parts such as kiln body, hydraulic circulation system, heating electrical control system, exhaust system, etc., as follows: 1. Kiln body: It is the most important part of the electric kiln, generally assembled from more than ten sections. The kiln body is mainly composed of furnace cavity, kiln bottom, track, push plate, kiln wall, kiln roof, kiln entrance and kiln exit. The furnace cavity is divided into three zones: heating, heat preservation and cooling. The shell of the kiln body is welded by steel plates. In the heating zone and high temperature zone, heavy refractory bricks are mainly used as the frame, and heavy refractory bricks are used as the insulation material for the kiln wall...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F27B5/14F27B5/00C04B35/622F27B5/06F27B5/08C04B35/26

Inventor 罗代贵陶勋强唐艳华

Owner 四川川西磁业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com