Volatile communication structure for end furnace chambers of carbon secondary roasting furnace

A technology of secondary roasting and volatile matter, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of local material box safety hazards, poor circulation of volatile matter, uneven volatile matter amount, etc., to improve the secondary roasting. The effect of quality, smooth passage, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further illustrated through the description of specific embodiments below, but the protection scope of the present invention is not limited by the examples. Those skilled in the art can make various modifications or improvements according to the basic idea of the present invention, but as long as they do not deviate from the basic idea of the present invention, they all fall within the scope of the present invention.

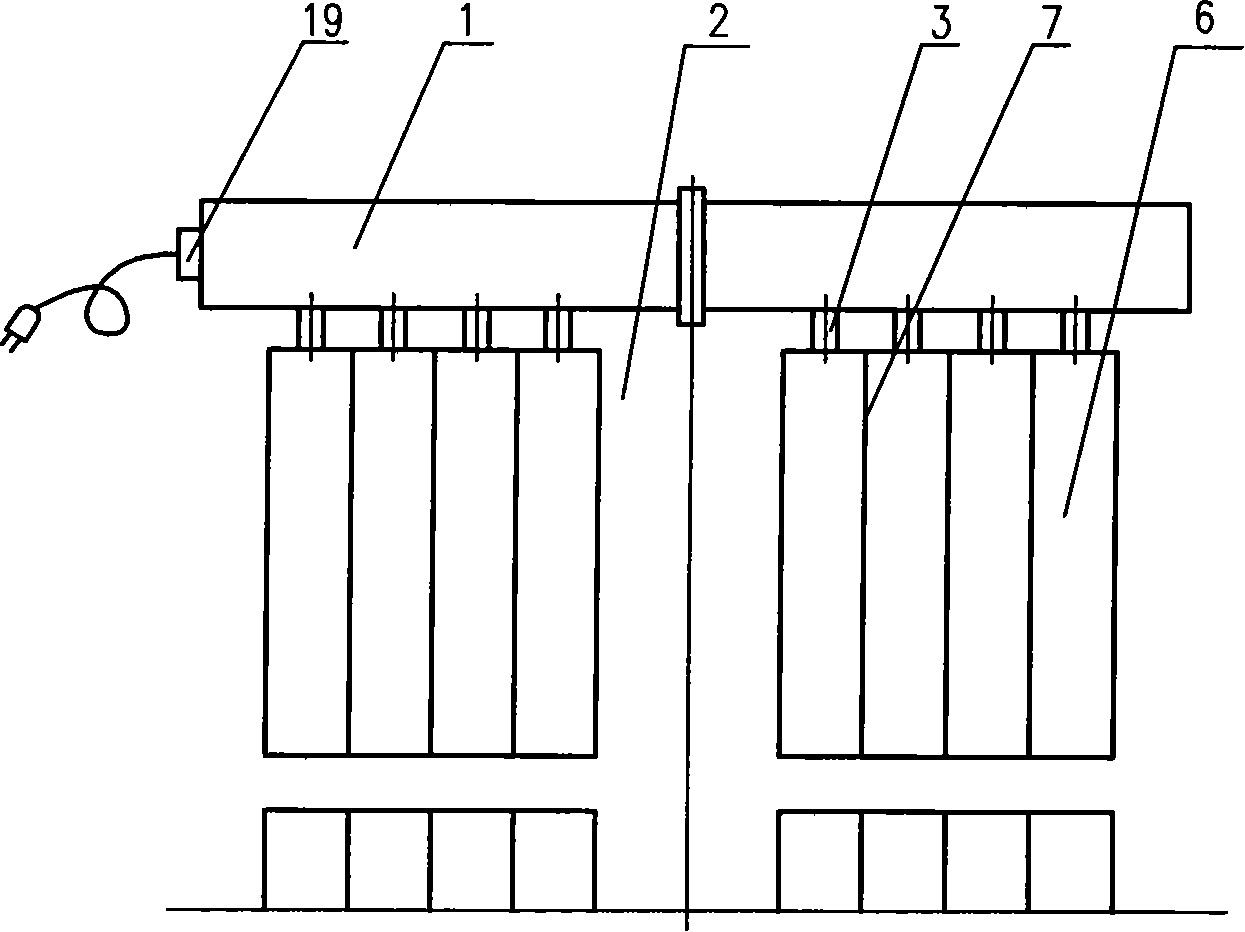

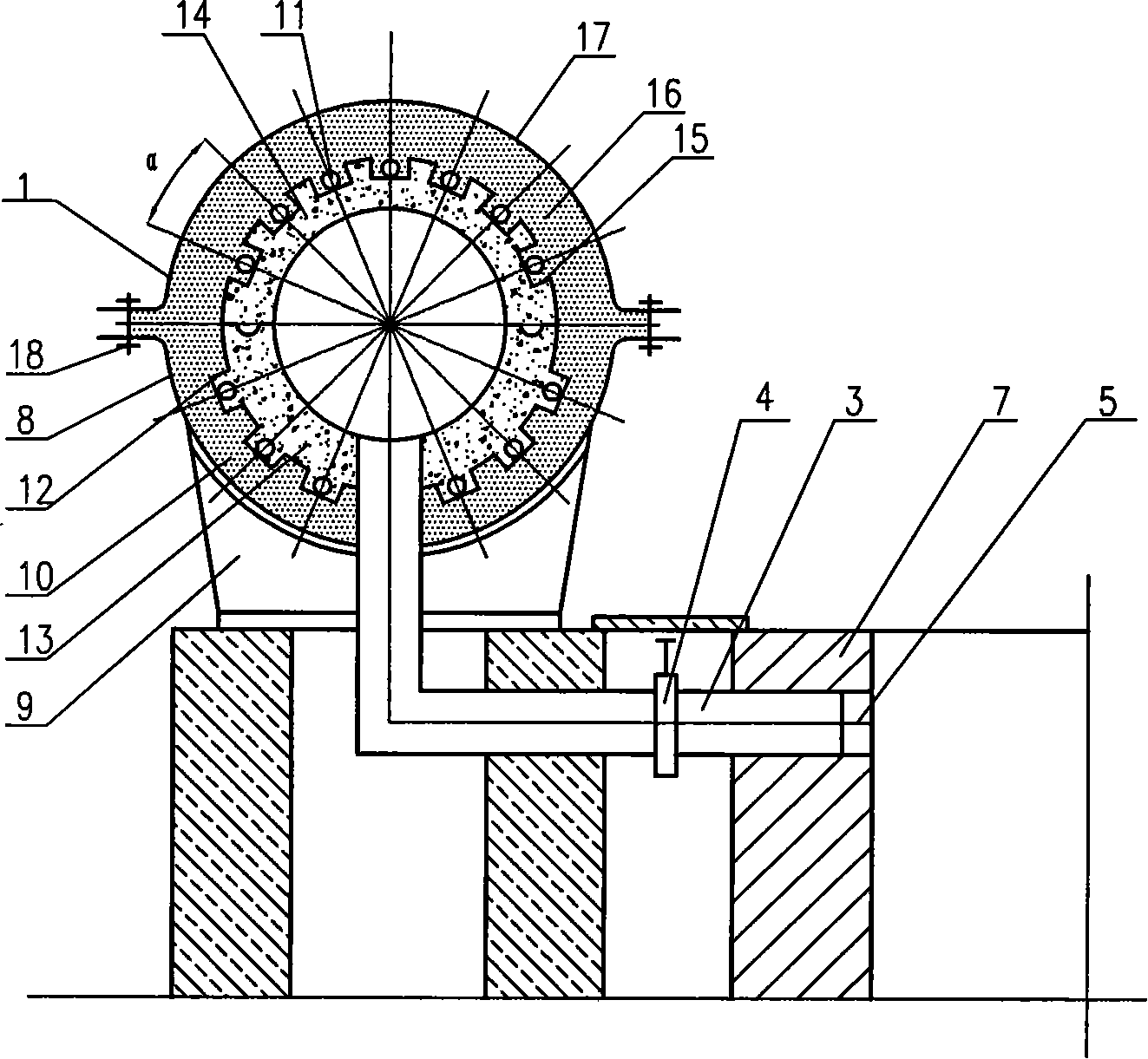

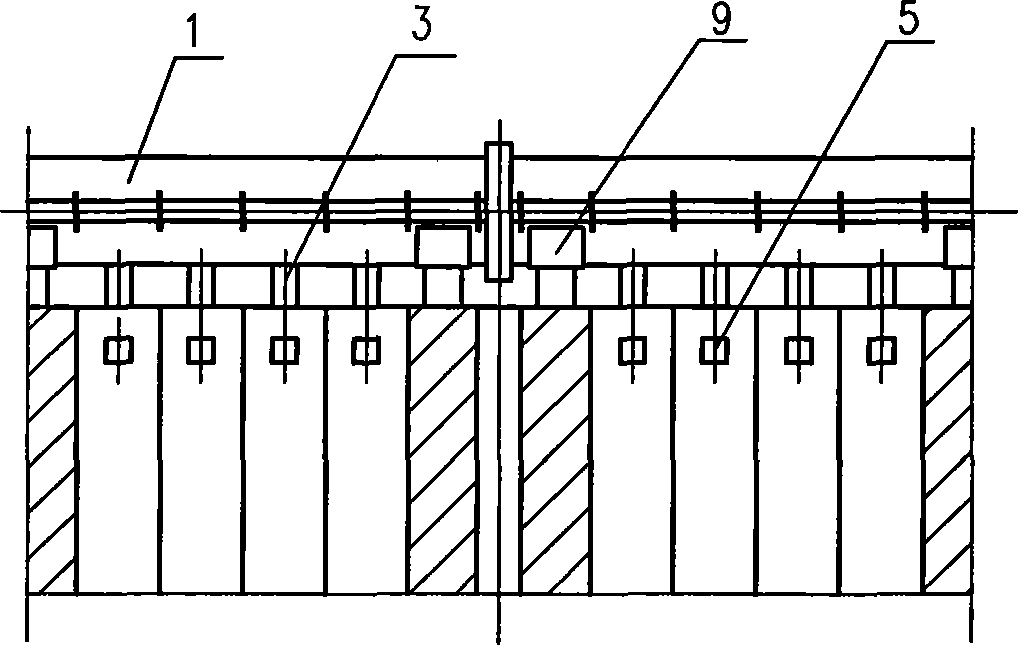

[0034] Such as figure 1 with image 3 Shown, the present invention a kind of carbon secondary roasting furnace end furnace chamber volatile component communicating structure, comprises carbon secondary roasting furnace 2, is provided with volatile component communicating device 1 on the operating surface of carbon secondary roasting furnace 2 two ends, The end of each material box 6 in the end furnace chamber is provided with a material box volatile matter inlet and outlet 5, and the cross-sectional shape of the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com