Method and device for measuring thickness of non-conductive coating layer on inner surface of capacitance metal

A coating thickness and non-conductive technology, which is applied in the field of non-conductive coating thickness measurement, can solve the problems of large volume and inconvenient detection of inner surface coating thickness, etc., and achieve high measurement accuracy, strong anti-interference ability and good robustness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

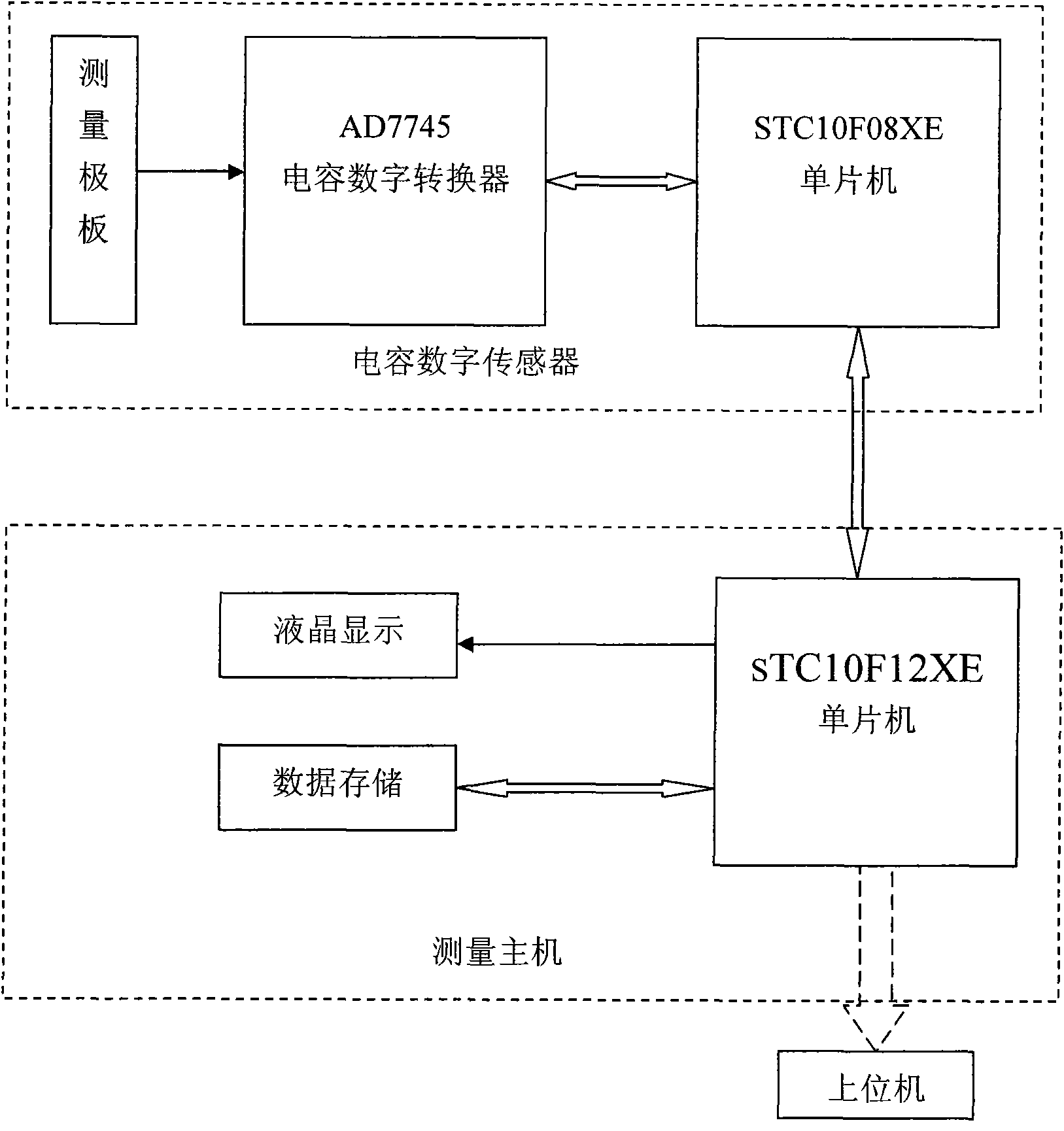

[0010] according to figure 1 As shown, the measurement device of the present invention is composed of two parts, a capacitance digital sensor and a measurement host, wherein the capacitance digital sensor includes: two measurement plates, a capacitance-to-digital converter (integrated chip AD7745), a microprocessor (STC10F08XE) The measuring pole plate is composed of metal foil solidified on the flexible body, which can be closely attached to the surface of the workpiece to be tested during detection; the measuring pole plate is connected to the signal input terminal of the capacitance-to-digital converter, and the capacitance signal is converted into a digital signal. by I 2 The C bus is sent to the microprocessor (STC10F08XE), and the microprocessor (STC10F08XE) sends the processed signal to the single-chip microcomputer (STC10F12XE) in the measurement host; the microprocessor (STC10F08XE) also sends a control signal to the capacitance-to-digital converter to realize its fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com