Method for carrying out streamline-form thickening on airfoil shape tailing edge

A streamlined, airfoil-shaped technology, applied to wind turbines at right angles to the wind direction, wind turbines in line with the wind direction, and greenhouse gas reduction, can solve problems such as ambiguity and practical implementation difficulties, and achieve late stall, Good social value and economic value, the effect of improving the lift coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

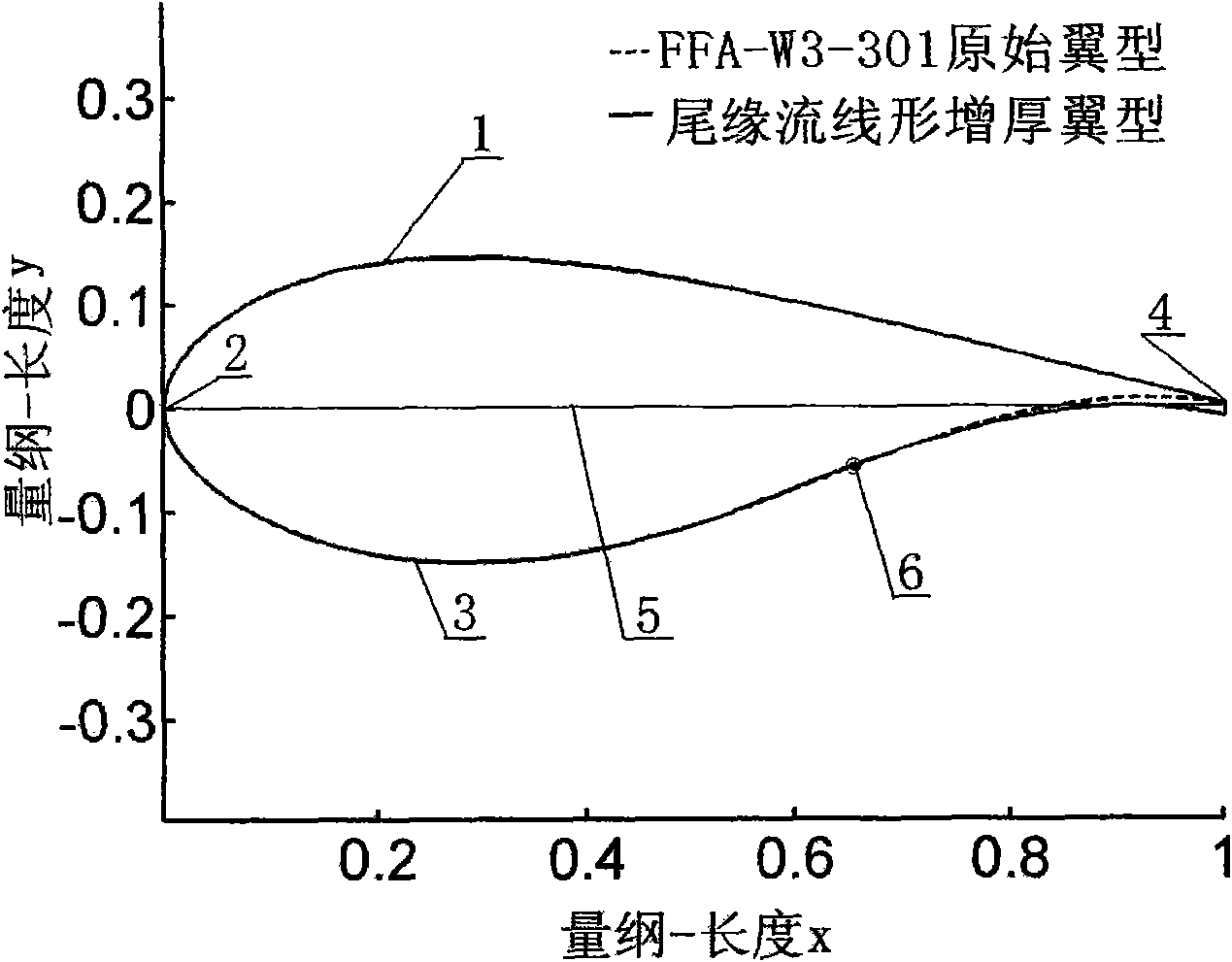

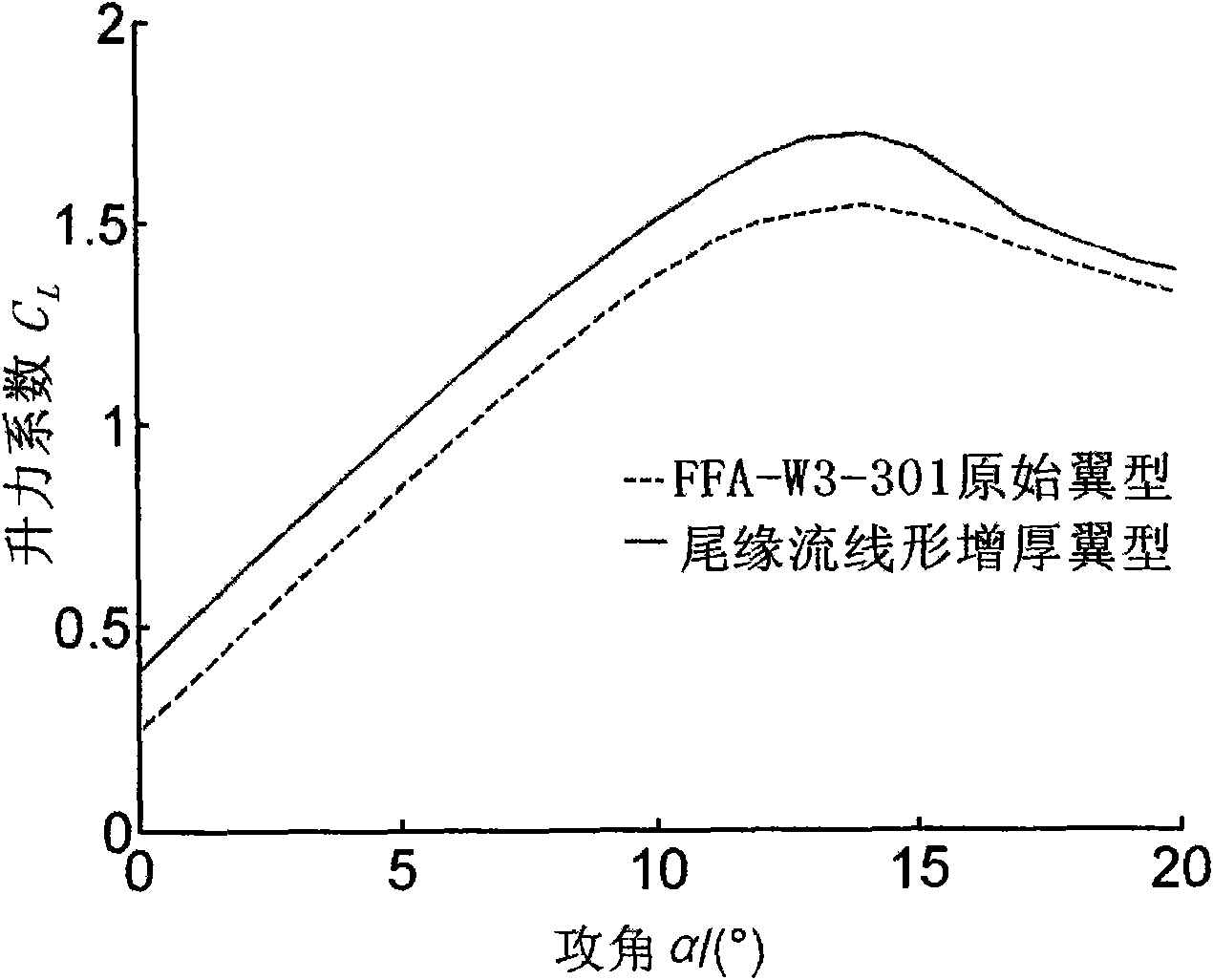

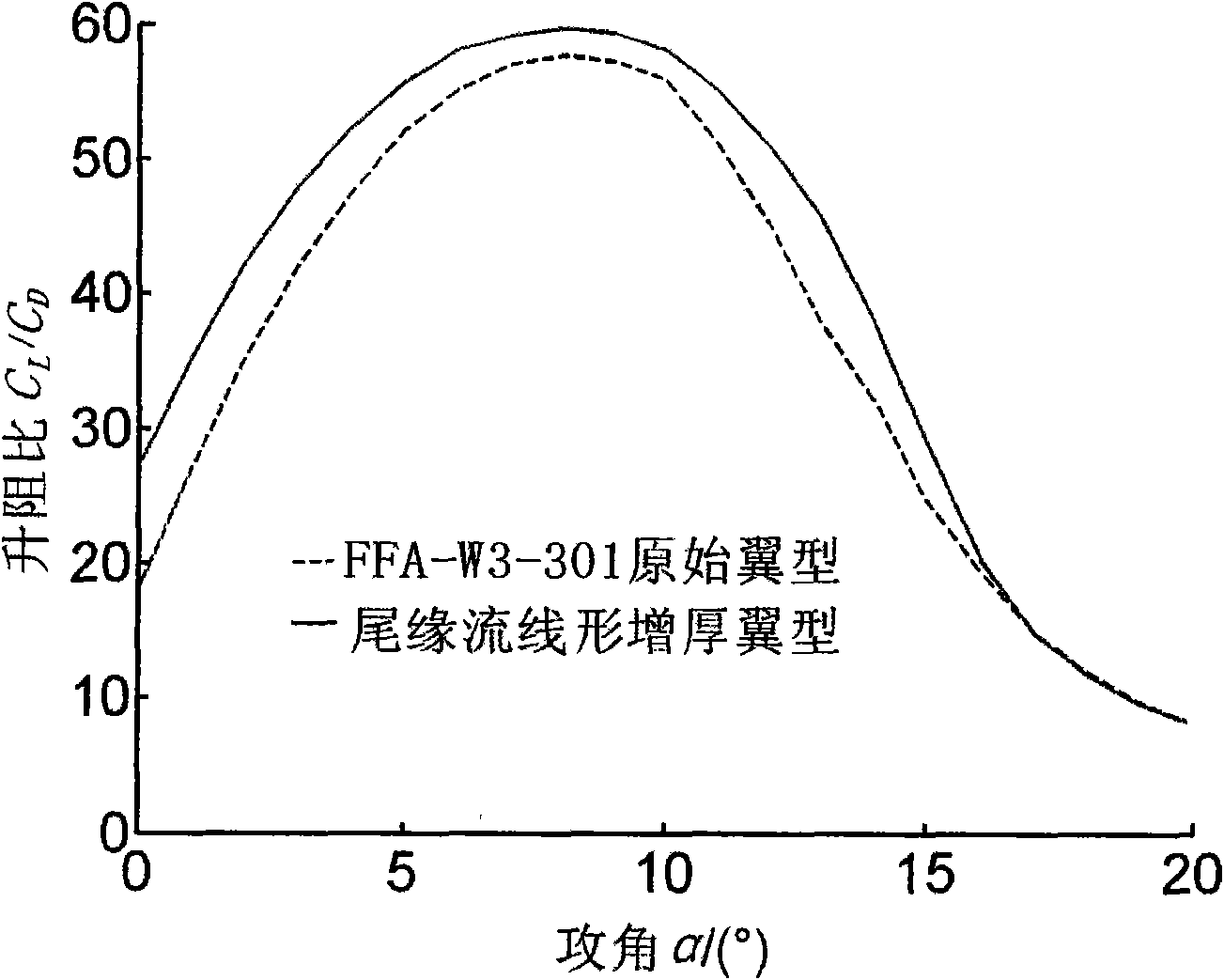

[0047] The FFA-W3-301 airfoil is selected as the original airfoil, and the trailing edge is streamlined and thickened according to the original airfoil. In the design process, the three parameters (τ, κ, ξ) in the control equation are selected as the control variables, and the average lift-to-drag ratio under the angle of attack of 5°-10° is used as the objective function, according to the genetic algorithm mentioned above The model is optimized. From the FFA-W3-301 airfoil as the original airfoil, the following figure 1 The streamlined thickened trailing edge airfoil shown.

[0048] The three parameters obtained from the FFA-W3-301 airfoil optimized for the original airfoil are:

[0049] (τ, κ, ξ) = (0.012, 0.68, 1.12)

[0050] That is, the thickness of the streamlined thickened trailing edge is 1.2% of the chord length, and the thickening starting point is at 68% of the chord length direction.

[0051] refer to figure 1 , the dotted line is the original airfoil of FFA-W...

Embodiment 2

[0053] The NACA63430 airfoil is selected as the original airfoil, and the trailing edge is streamlined and thickened according to the original airfoil. In the design process, the three parameters (τ, κ, ξ) in the control equation are selected as the control variables, and the average lift-to-drag ratio under the angle of attack of 5°-10° is used as the objective function, according to the genetic algorithm mentioned above The model is optimized. From the NACA63430 airfoil as the original airfoil respectively obtained as follows Figure 4 The streamlined thickened trailing edge airfoil shown.

[0054] The three parameters obtained by optimizing the original airfoil from the NACA63430 airfoil are:

[0055] (τ, κ, ξ) = (0.02, 0.85, 1.15)

[0056] That is, the thickness of the streamlined thickened trailing edge is 2% of the chord length, and the thickening starting point is at 85% of the chord length direction.

[0057] refer to Figure 4 , the dotted line is the original ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com