Preservation and controlled delivery/release of spermatozoa

A sperm and semen technology, applied in the field of biopolymer particles, can solve the problems of poor efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation of alginate beads is known to those skilled in the art, for example O. and G. (1990) Alginate as immobilization matrix forcells. Trends in Biotechnology 8, 71-78 and as disclosed in US 6,497,902.

[0071] A variety of gel solutions can be applied to form biopolymer particles, such as alginate beads. A variety of solutions suitable for forming particles of various biopolymers are well known to those skilled in the art. According to the invention, divalent ions (also referred to herein as gelling ions) such as calcium and barium may be used to form alginate particles, for example to effect gelation of said alginate. Alginate forms gels in the presence of various divalent and multivalent ions. The use of calcium ions resulted in rapid gelation and the formation of relatively strong particles. On the other hand, the use of barium ions forms even stronger particles that are more stable under physiological conditions. It will be appreciated that the typ...

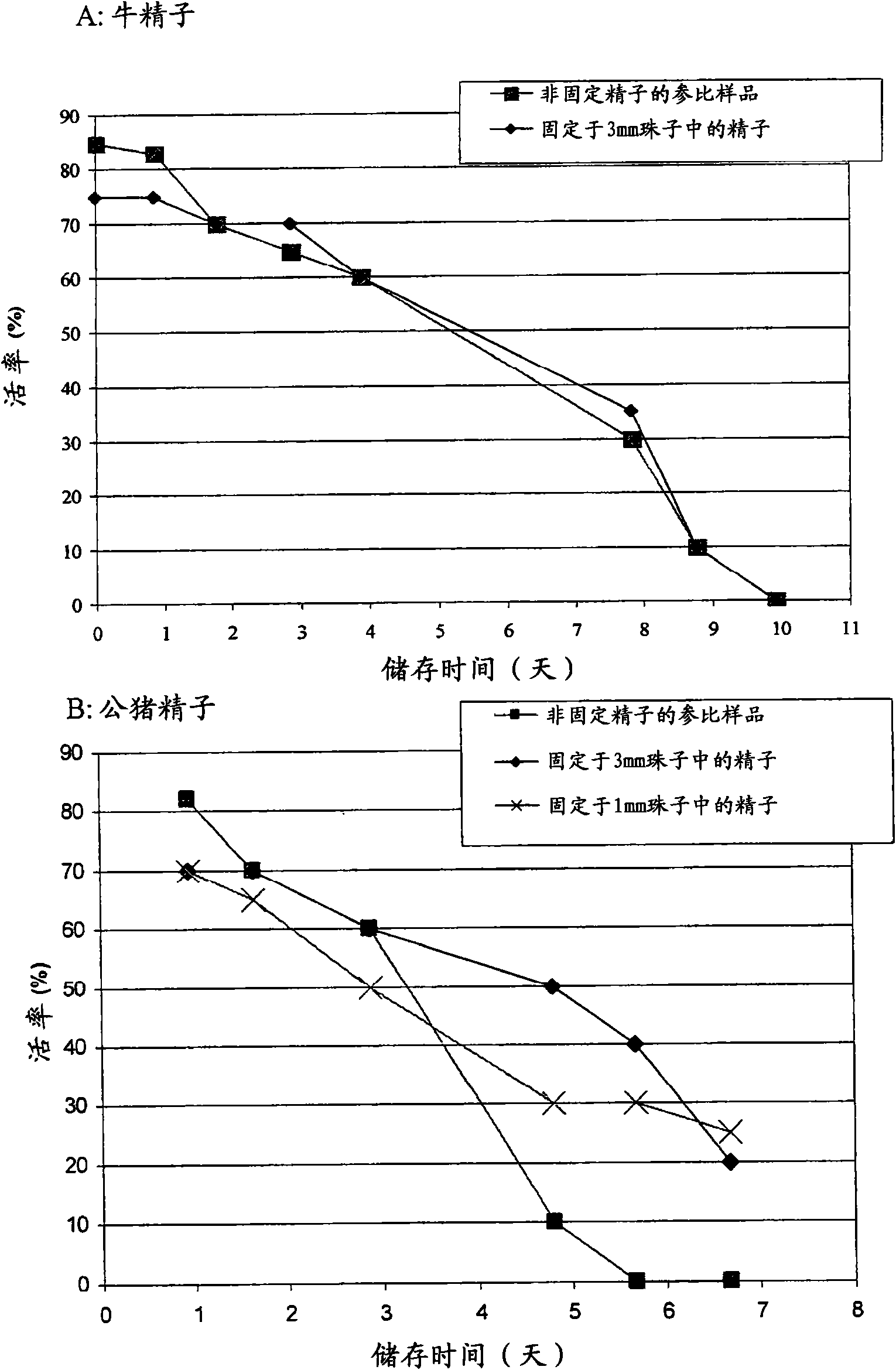

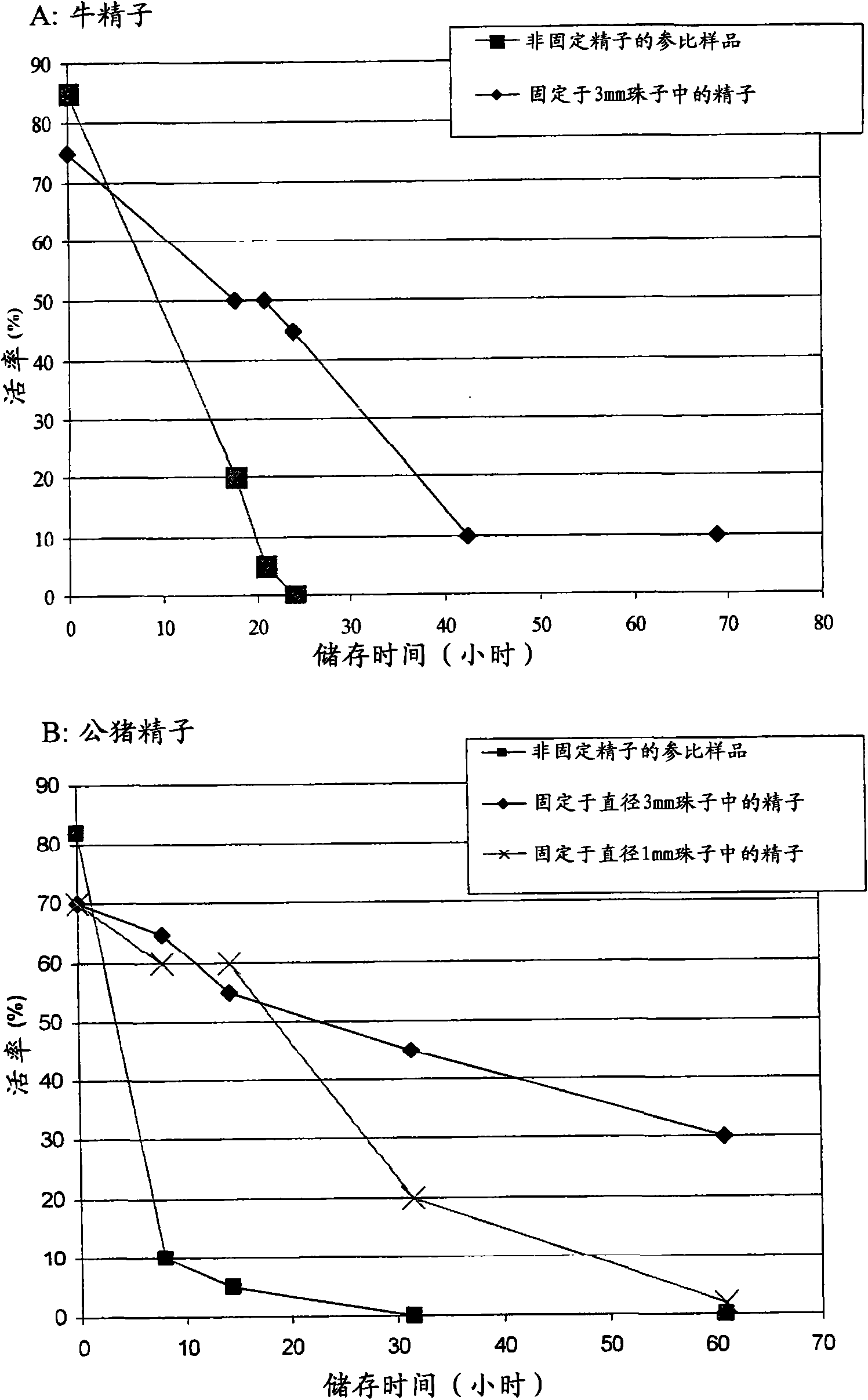

Embodiment 1

[0107] Example 1 Immobilization of spermatozoa in alginate

[0108] Materials and methods

[0109] Material

[0110] The following chemicals were used: from Riedel de (Seelze, Germany) CaCl 2 ·H 2 O, K 2 HPO 4 , NaH 2 PO 4 , NaCl and sodium citrate; dextrose monohydrate from Norsk Medisinaldepot (Oslo, Norway); sodium alginate (PROTANAL LF 10 / 60) supplied by FMC Biopolymer A / S (Drammen, Norway);

[0111] sperm source

[0112] bovine sperm in Acquisition at Geno Experimental Field (Genofacility) in Trondheim, Norway. Boar spermatozoa were collected at Norsvin Experimental Farm, Hamar, Norway. Bovine spermatozoa were diluted 1+2 in milk diluent shortly after ejaculation. Boar spermatozoa were diluted 1+4 in TRI X-CELL (IMV Technologies, L'Aigle Cedex, France). This dilution or choice of dilution buffer is not critical to the immobilization procedure or the long-term survival of the sperm after immobilization, but merely to facilitate storage of the sperm until fur...

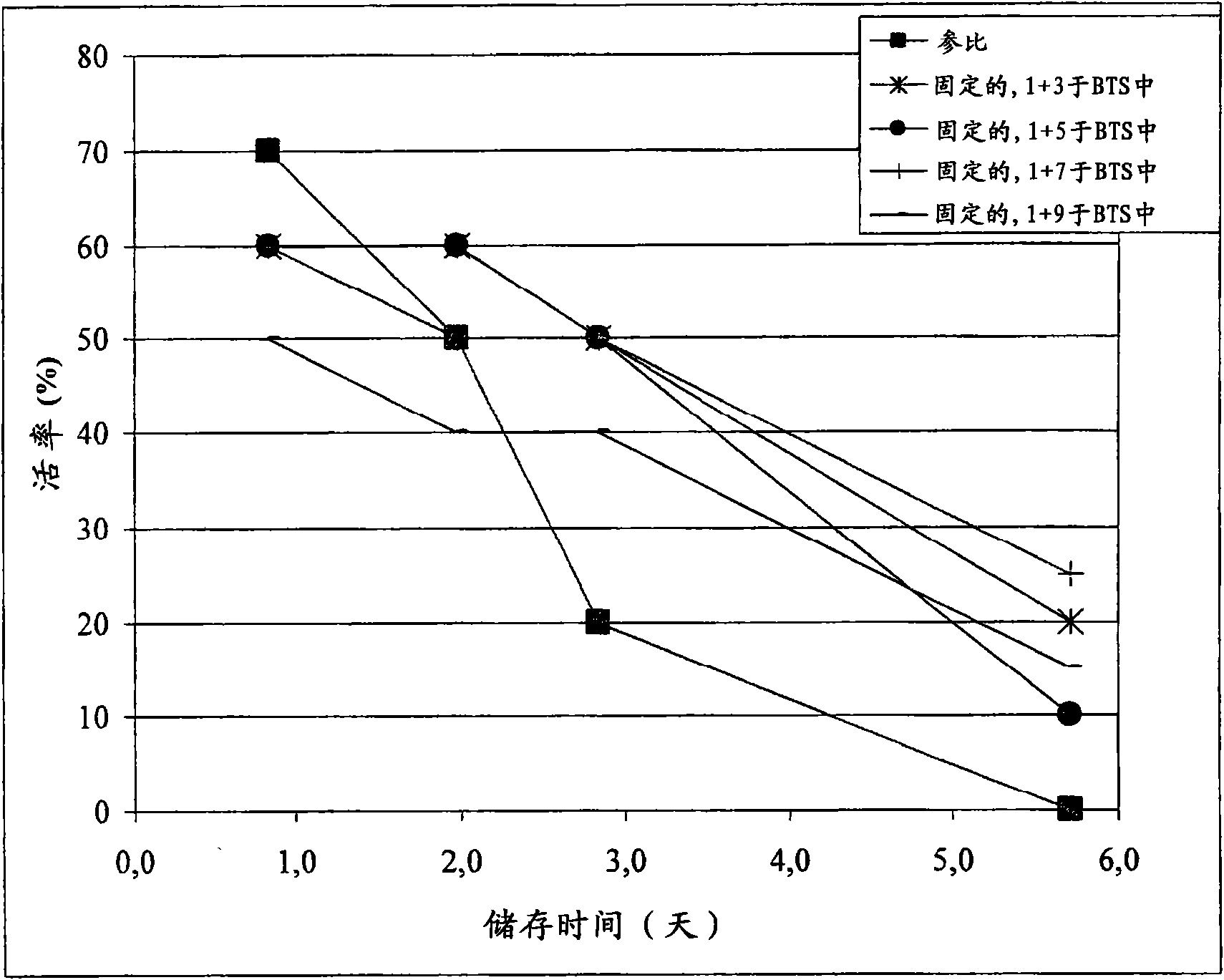

Embodiment 2

[0150] Embodiment 2 The energy consumption of immobilizing spermatozoa

[0151] Without being bound by a particular theory, it is believed that immobilization of spermatozoa results in a reduction in the energy expended by the spermatozoa, which is beneficial for storage life and their fertilization capacity.

[0152] Therefore, in order to study this theory, bovine spermatozoa were collected at about 150×IO 6 The concentration of spermatozoa / ml was fixed in alginate pellets and added to 2 times the volume of the beads in milk dilution buffer. A reference sample containing free-suspended spermatozoa was prepared from the same ejaculate at Each total volume of milk dilution buffer contains the same total sperm concentration. at 20°C, prior to storage, under N 2 The samples were prepared under anaerobic conditions of airflow. The milk dilution buffer was sampled during storage and the lactate produced by the sperm in the sample was measured by HPLC. The results are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com