Gas naphthalene washing process in primary-cooling working procedure of coke oven gas purification unit

A purification unit and coke oven gas technology, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve problems such as high energy consumption, complicated process flow, and many equipment, so as to reduce process energy consumption and operation The effect of simplicity and a small number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

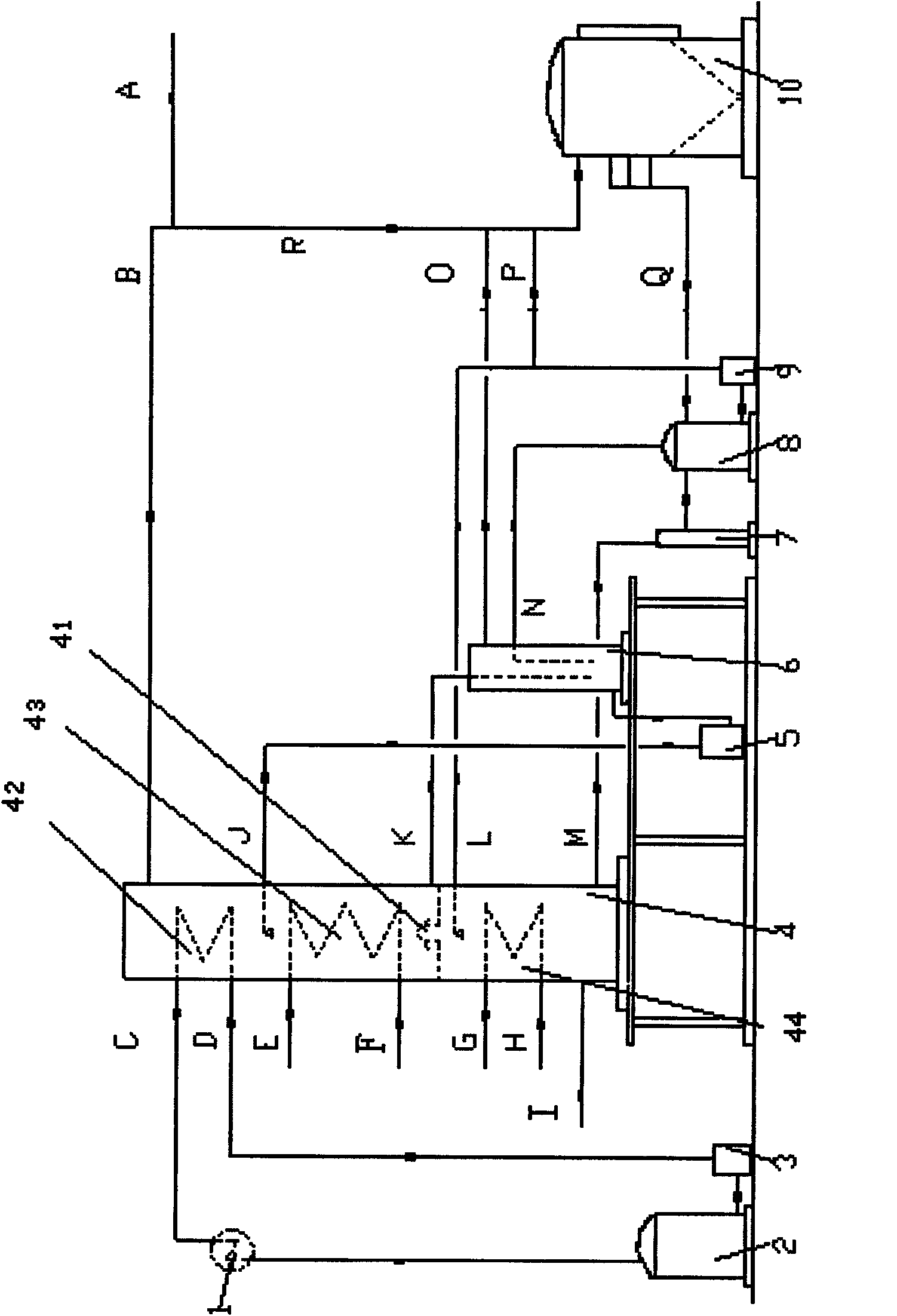

[0023] Example 1: To fit 220 x 10 4 Ton coke / year coke oven battery, gas treatment capacity 13×10 4 m 3 / h meter, the normal gas flow is about 12×10 4 m 3 / h,

[0024] 1. Separation of raw gas:

[0025] The raw gas A from the coke oven is divided into crude coke oven gas B and tar ammonia water mixture R through the upward climbing of the pipeline, and the tar ammonia water mixture R flows to the tar ammonia water separation tank 10 by itself.

[0026] 2. Preparation of the upper condensate:

[0027] The crude coke oven gas B enters the gas cooler 4. The crude coke oven gas B contains 81t / h of water; 5.48t / h of tar; 1.02t / h of naphthalene. The section 43 and the cooling water section 44 of the second stage of the process, and the liquid separator 41 are arranged between the cooling water section 43 of the first stage of the process and the cooling water section 44 of the second stage of the process. The temperature of the hot water outlet C of the hot water section 42 i...

Embodiment 2

[0035] In order to prevent that the tar content of the circulating naphthalene washing liquid is too low or the naphthalene content is too high, affecting the naphthalene washing effect, the emulsion Q of 10 in the tar ammonia water separation tank can also be filled into the lower section of the circulating naphthalene washing liquid tank 8 in a self-flowing mode.

Embodiment 3

[0037] In order to further reduce the naphthalene content in the purified gas at 100-350mg / m 3 Within the range, a small amount of water-containing tar or tar washing oil is continuously added to the lower part of the circulating naphthalene washing liquid tank 8 to further reduce the naphthalene content of the tar in the circulating naphthalene washing liquid. The supplementary tar comes from the tar ammonia water separation tank, the mechanized tar ammonia water clarification tank or the hydrous tar separated from the mechanized tar clarification tank; the supplementary tar washing oil is a product of deep processing of tar. Depending on the requirements of different gas naphthalene content purification indicators, the naphthalene content of tar in the circulating naphthalene washing liquid is controlled within the range of 6-24wt% by controlling the supplementary amount of aqueous tar or tar washing oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com