Powder feeder without mechanical transmission mechanism

A transmission mechanism, non-mechanical technology, applied in the direction of metal material coating process, coating, etc., can solve problems such as sticking and wear

Active Publication Date: 2010-11-24

河南省煤科院耐磨技术有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

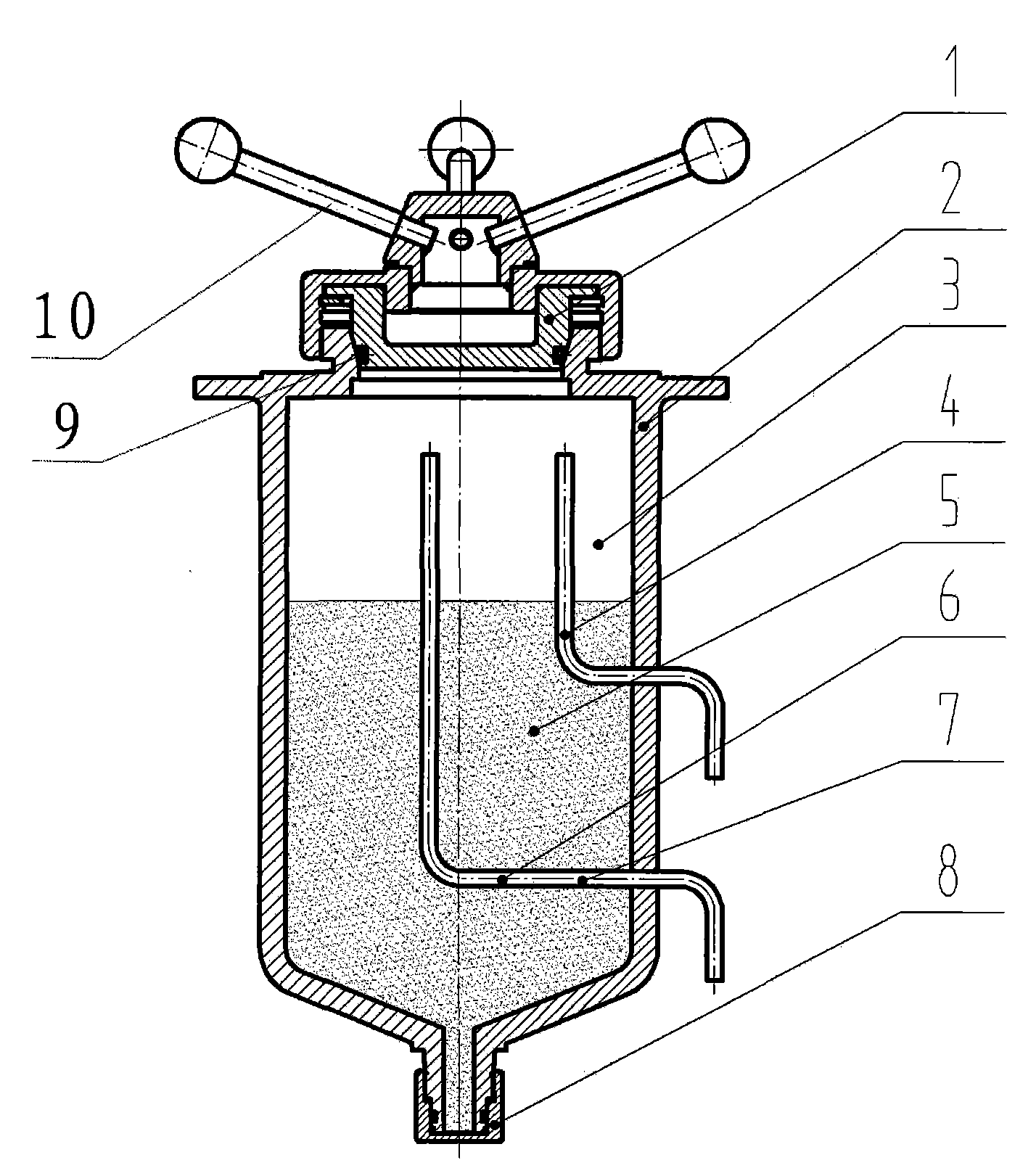

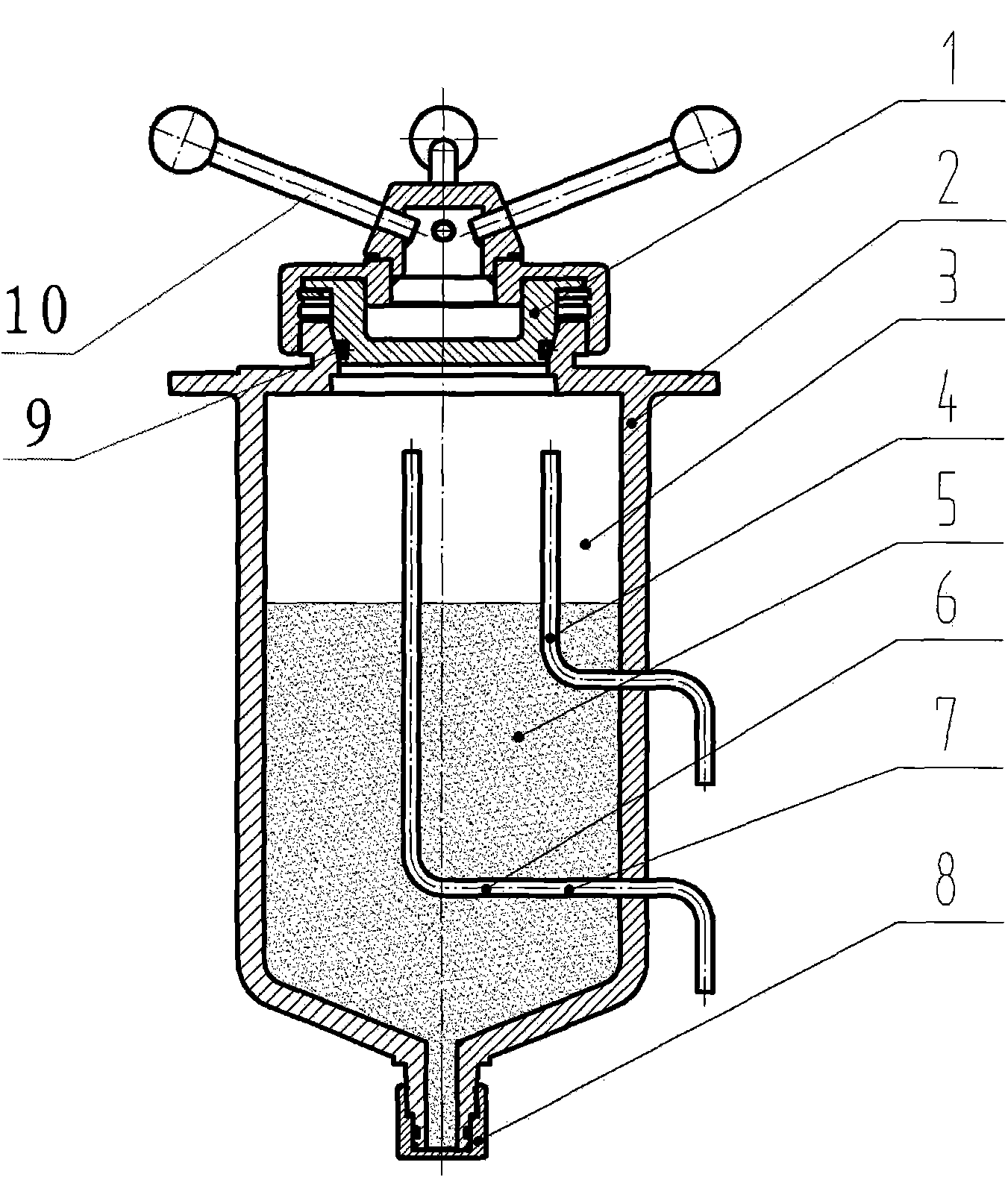

In view of the above situation, in order to overcome the defects of the prior art, the purpose of the present invention is to provide a powder feeder without a mechanical transmission mechanism, which can effectively solve the faults caused by the failure, stagnation and wear of the mechanical transmission device of the existing powder feeder. In order to ensure the long service life of the powder feeder, energy saving and stable powder feeding, the technical solution is to load the powder from the lower part of the closed cavity, and the powder feeding gas enters the upper part of the closed cavity through the intake pipe to form a pressure chamber. The pressure gas in the chamber has two functions: one is to enter the powder gas pipe and flow out and form a jet gas in the pipe; the other is to pressurize the powder in the powder storage chamber to make it easier to enter the powder through the small hole on the powder gas pipe. Intratracheal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a powder feeder without a mechanical transmission mechanism, which can effectively solve the defaults caused by the malfunction, the clamping stagnation and the abrasion of a mechanical transmission mechanism of the prior powder feeder and accordingly ensures that the powder feeder has long service life, saves energy and stably feeds powder. The powder feeder adopts the technical scheme of comprising a shell and an air pipe, wherein a closed cavity which is through from top to bottom is formed in the shell; an air pressure chamber is arranged at the upper part of the closed cavity, and a powder storage chamber is arranged at the lower part of the air pressure chamber which is internally provided with an air inlet pipe and a powder air pipe; the upper ends of the air inlet pipe and the powder air pipe in the closed cavity are respectively provided with openings at the upper part of the air pressure chamber; the lower ends of the air inlet pipe and the powder air pipe penetrate through the shell towards the exterior of the shell; and the closed cavity, a powder-feeding cover with a sealing ring and a powder-discharging cover with a sealing ring form an integral sealing structure. The invention has novel and unique structure, low energy consumption, no mechanical abrasion, long service life, high working efficiency, small size and low manufacture cost.

Description

Powder feeder without mechanical drive 1. Technical field The invention relates to a powder conveying device in the field of laser and plasma cladding, in particular to a powder feeder without a mechanical transmission mechanism suitable for plasma cladding and smelting equipment. 2. Background technology With the development of material science, the application of surface modification of metal materials is becoming more and more extensive, and more and more processes and equipment are being implemented, which are becoming more and more advanced. From flame spraying, welding rod, welding wire surfacing to today's laser And plasma cladding, melting and other processes. Among the above technologies and equipment, the powder feeder is an important part of the whole system. At present, the feeding methods of powder feeders commonly used in industry include spiral type, scraper type, electromagnetic type, super-audio frequency vibration type and gravity type, etc. These powde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C24/10

Inventor 刘鸣放王春林杨炳马宗彬

Owner 河南省煤科院耐磨技术有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com