Machine for forming underground continuous water-retaining walls by one step

A technology for forming machines and retaining walls, which is applied to sheet pile walls, earth movers/excavators, buildings, etc., can solve the problems of long construction period, low production efficiency, high construction cost, etc., and achieve high degree of automation and work High efficiency and good water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

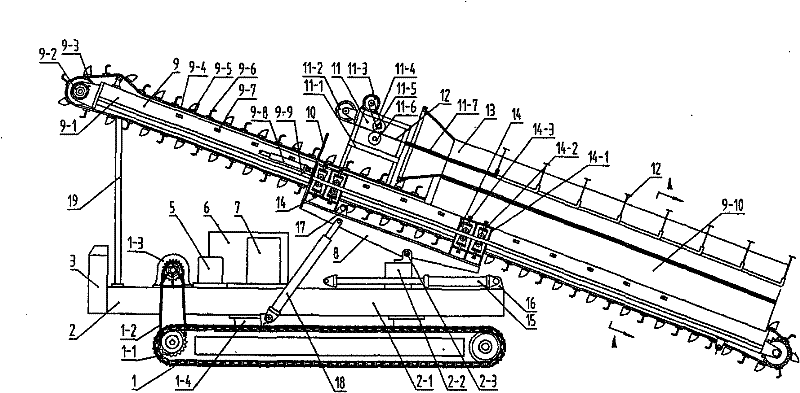

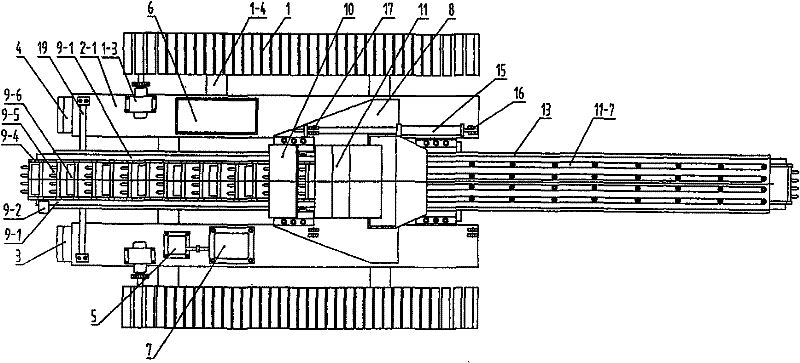

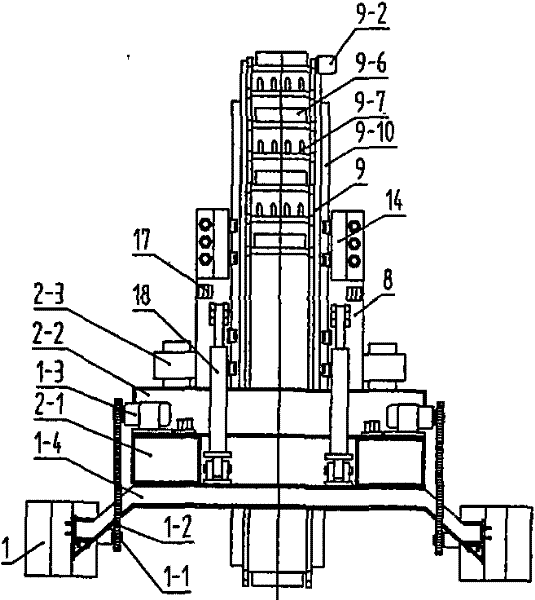

[0023] Such as figure 1 , figure 2 , image 3 Shown: The one-step molding machine for underground continuous water retaining wall includes: crawler chassis 1, frame 2, corner chassis 8 installed on the upper part of frame 2 and can rotate, groove digging system 9 installed on corner chassis 8, reinforcement system 11 , concrete pouring tank 13, a power system composed of diesel engine 7, oil pump 5 and fuel tank 6 installed on the frame 2, an electrical control cabinet 3 and a hydraulic control cabinet 4 installed on the front of the frame 2, and a plurality of hydraulic control cabinets. drive motor and connecting oil pipe; two driving sprockets I1-1 on the crawler chassis 1 are connected with the crawler motor 1-3 installed on the frame 2 through the chain I1-2; the frame 2 is two A rectangular steel structure cabinet frame composed of a longitudinal beam 2-1 and a plurality of beams 2-2, the lower part of the frame 2 is connected with the two front and rear axles 1-4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com