Paper sheet handling device and coil forming device

一种纸张处理装置、线圈的技术,应用在薄料处理、装订、线材加工等方向,能够解决难以实现包装机小型化、低成本化、难装置小型化等问题,达到再现性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

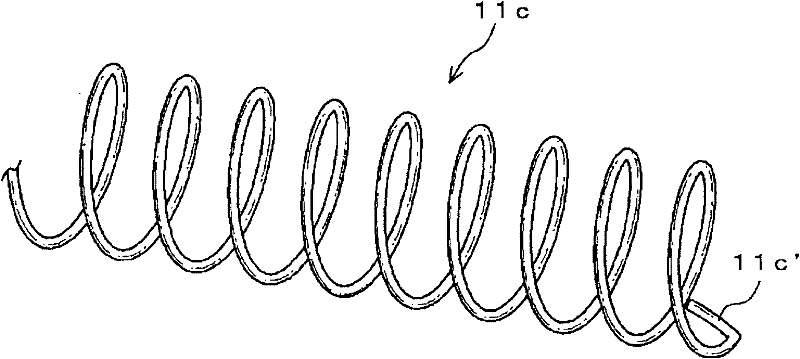

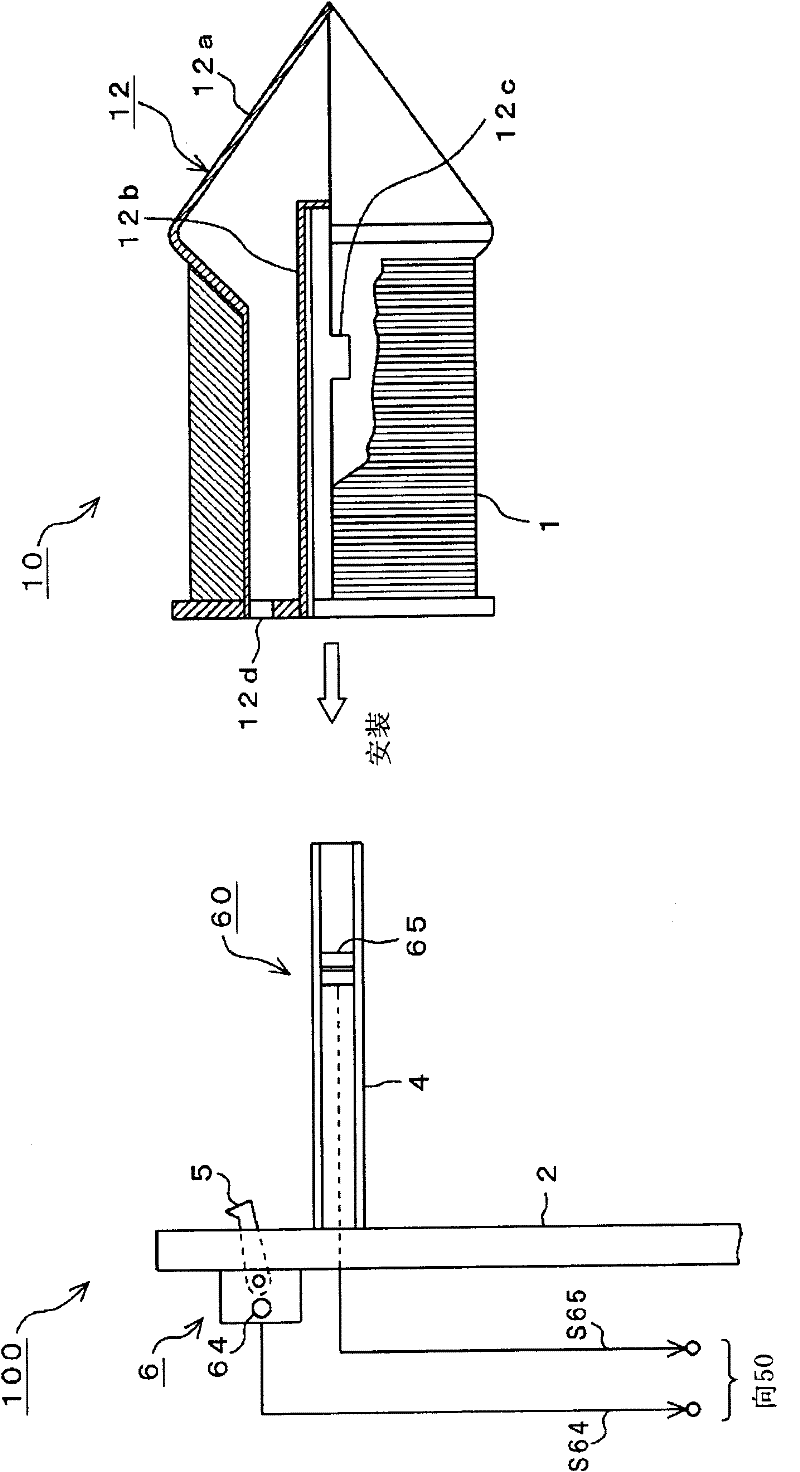

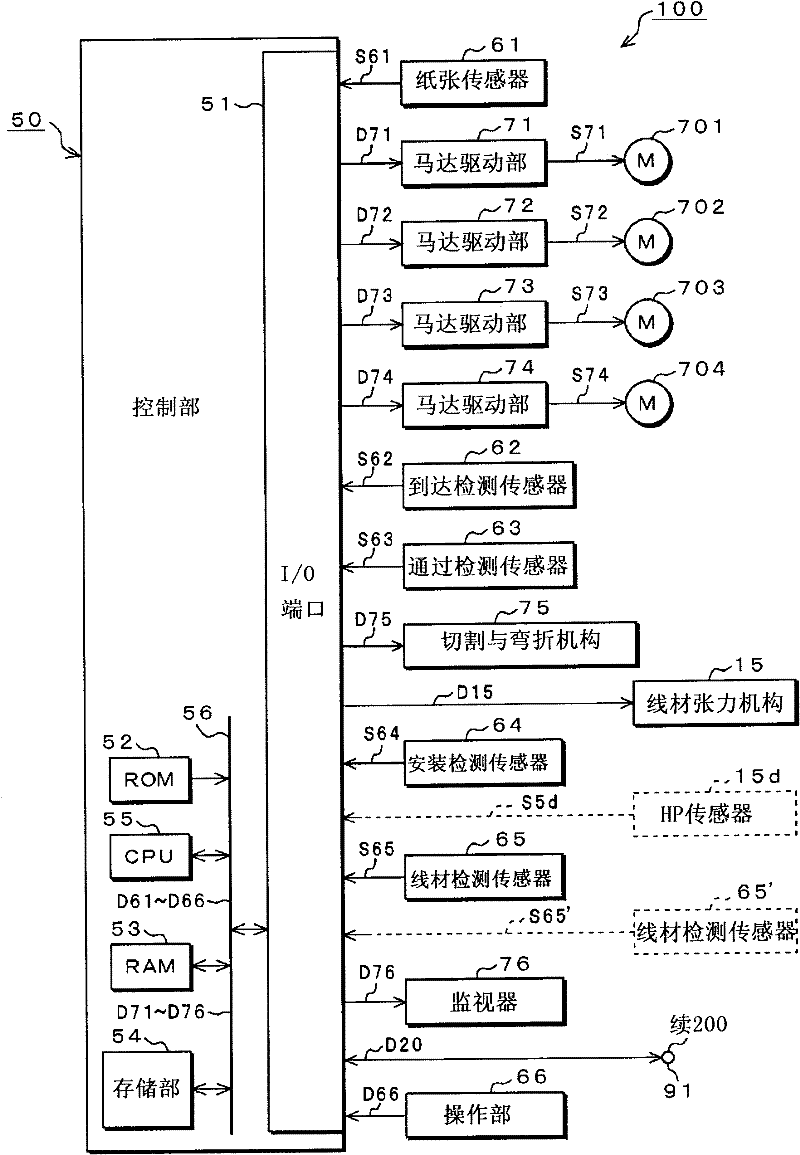

[0351] Next, refer to Figure 40 A paper processing method in the image forming system 101 as the first embodiment of the present invention will be described. Figure 40 The image forming system 101 shown is a bundle processing system including an image forming apparatus 200 such as a packaging machine 100 ′ according to the present invention, a copier, or a printer, and bundles sheets P output from the image forming apparatus 200 into bundles of a predetermined thickness. The wire 1 is formed into a helical coil 11, and the paper bundle 3 is bound by the coil.

[0352] The image forming apparatus 200 forms an image on predetermined paper P for obtaining the paper bundle 3 and outputs the image. The image forming apparatus 200 has an image forming unit 207 , a monitor 208 , an operation unit 209 , and a control unit 210 . The image forming unit 207 receives the image control data D27, forms a monochrome image or a color image on a predetermined paper P, and outputs it. The ...

Embodiment 2

[0398] Next, refer to Figure 42 A configuration example of the coil binding machine 102 as the second embodiment according to the present invention will be described. Figure 42 The shown coil binding machine 102 constitutes the function of the fourth paper processing device, which is obtained from Figure 40 In the shown packaging machine 100', the processing device after removing the punching processing function and the automatic cutting and bending functions realizes the manual mode.

[0399]The coil binding machine 102 is a sheet processing device applicable to the second image forming system. In the second image forming system, the paper P outputted from the image forming apparatus 200 such as a copying machine and a printer described in the first image forming system 101 is separately punched with a dedicated or commercially available punching machine, and then processed. The perforated paper P is bundled and placed on the coil binding machine 102 .

[0400] The coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com