Spray paint waste gas purification device and purification method therefor

A technology for waste gas purification and equipment, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high regeneration cost, large resistance, and large equipment, and achieve the effect of high purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

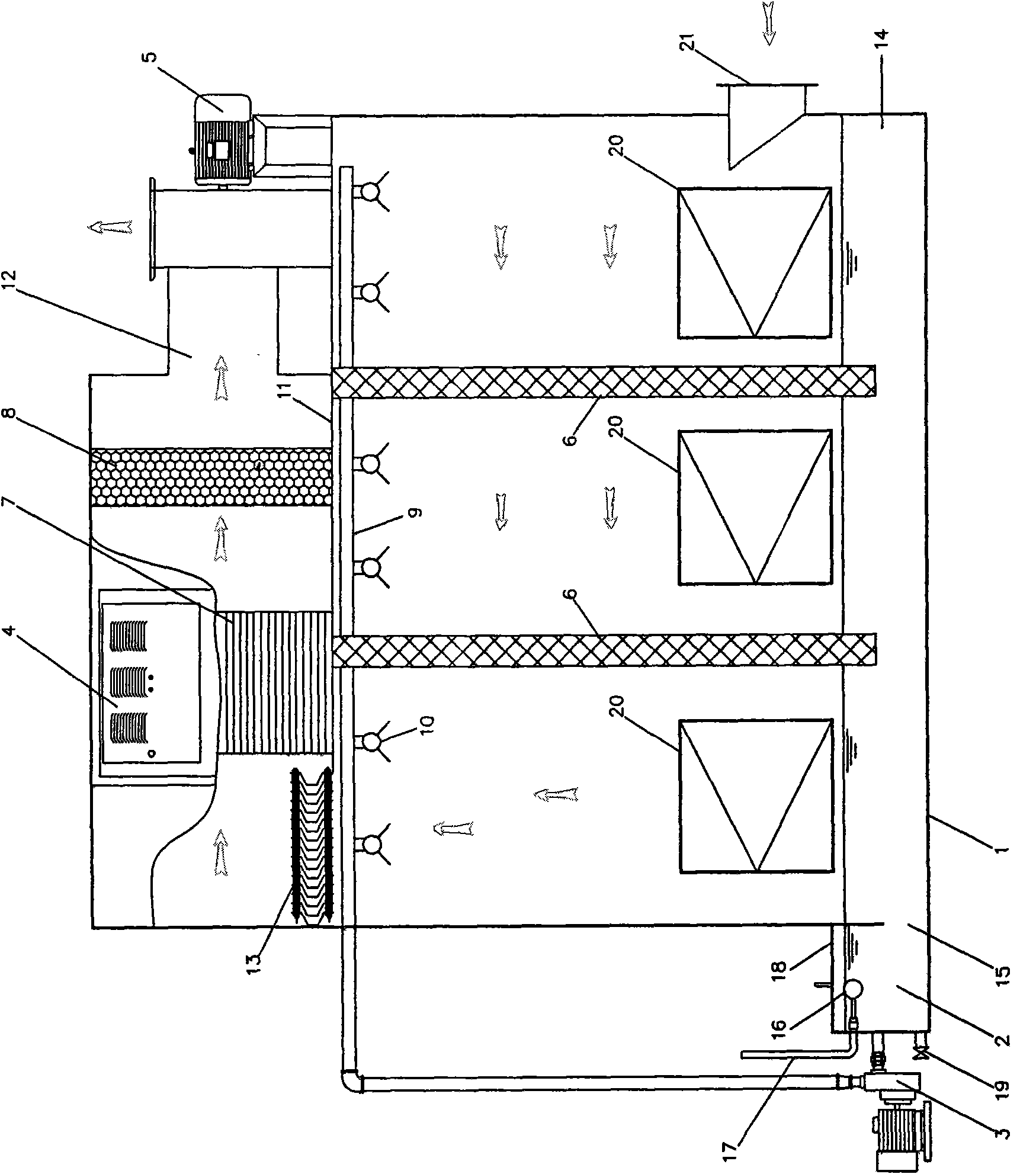

[0010] refer to figure 1 , a kind of exhaust gas purification equipment for spraying paint according to the present invention, comprising a main body 1, a liquid replenishment tank 2 arranged outside the main body 1 and communicating with the main body 1, an inlet 21, an outlet 12 and an induced draft fan 5 connected to the outlet 12, and the main body 1 is provided with activated carbon adsorption The unit 8, the spray pipe network 9 and the nozzle 10, the circulating water pump 3 are connected to the spray pipe network 9 and the liquid replenishment tank 2, and the inside of the main body 1 is divided into upper and lower layers connected to the left side by a transverse partition 11, and the activated carbon adsorbs The unit 8 is located on the upper floor and on the left side of the outlet 12. The upper floor of the body 1 is located on the left side of the activated carbon adsorption unit 8. A low-temperature plasma reactor unit 7 and a mist eliminator 13 that seals the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com