Drum-type washing machine

A drum-type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing machine control devices, etc., can solve unknown problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

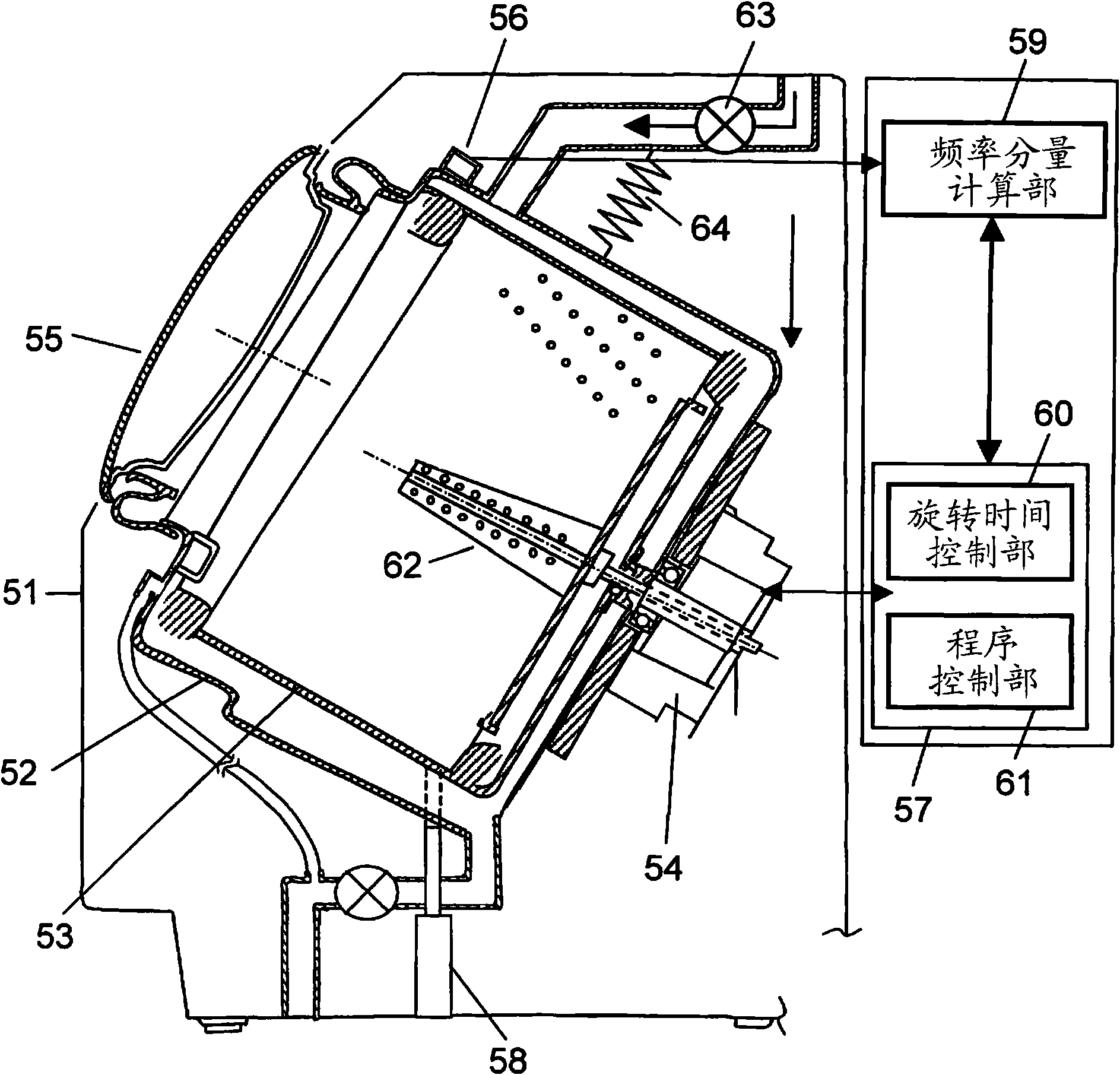

[0023] figure 1 It is a vertical cross-sectional view showing the structure of a drum-type washing and drying machine according to an embodiment of the present invention. exist figure 1 Among them, the water tank 52 with the rotating drum 53 freely rotatable is elastically anti-vibration supported on the main body of the laundry, that is, the inside of the housing 51, by elastic support mechanisms such as springs 64 and shock absorbers 58. Washing tank for washing.

[0024] The rotary drum 53 is rotationally driven in combination with a motor 54 , a drive unit fixed to the right outer wall of the water tank 52 . The laundry is agitated and washed by hammer washing in which the laundry is picked up by a plurality of agitation projections 62 formed on the inner wall of the rotary drum 53 and then dropped. The motor 54 for rotationally driving the rotating drum 53 is constituted by a brushless motor or the like, has a variable rotation speed, and repeats normal rotation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com