Vibrating-mirror constant-temperature work system and control method thereof

A working system and constant temperature technology, which is applied in temperature control without auxiliary power supply, temperature control by electric mode, tool manufacturing, etc., can solve problems such as limited temperature control accuracy, large temperature fluctuation of galvanometer, and influence on working accuracy, etc., to achieve The effect of small temperature fluctuation and high temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention provides a vibrating mirror constant temperature working system. The embodiment of the present invention also provides a control method of the system, which will be described in detail below.

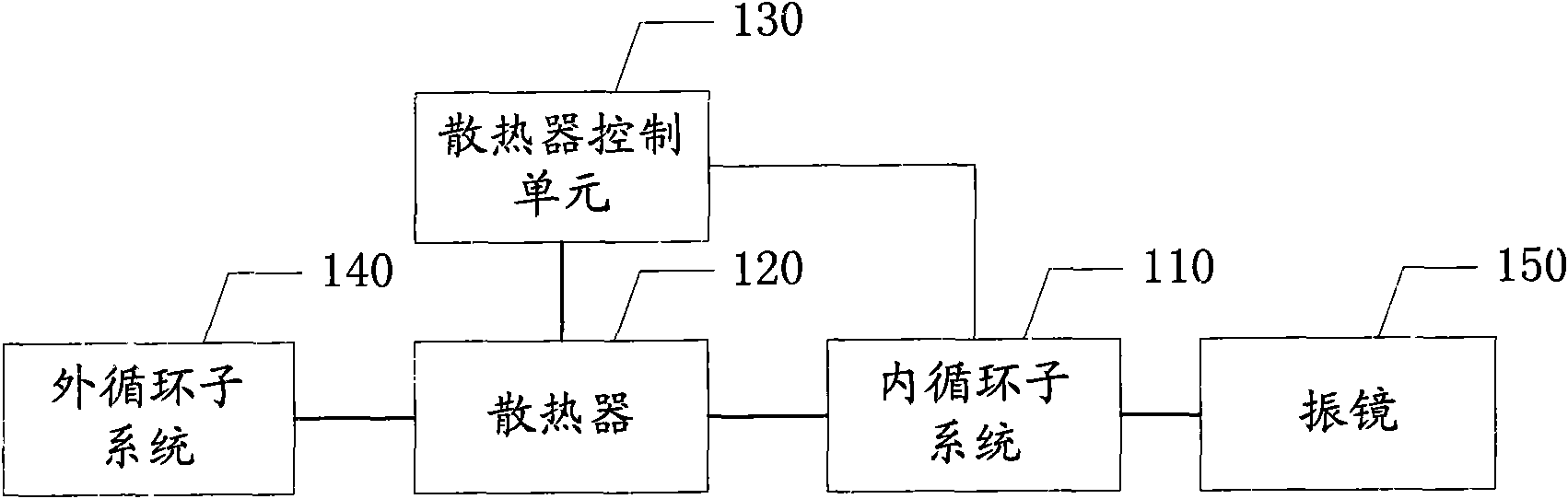

[0017] Embodiment 1 of the galvanometer constant temperature working system of the present invention: reference figure 1 , the vibrating mirror constant temperature working system of this embodiment includes an inner circulation subsystem 110, a radiator 120, a radiator control unit 130 and an outer circulation subsystem 140, wherein:

[0018] The internal circulation subsystem 110 is used to take out the heat of the vibrating mirror 150 .

[0019] The radiator control unit 130 is used to control the radiator 120 to start working when the temperature of the internal circulation subsystem 110 exceeds a predetermined range, so that the radiator 120 transfers the heat in the internal circulation subsystem 110 to the external circulation subsys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com