Temperature control device for optical glass window of temperature test box and using method

A technology of temperature test and optical glass, which is applied in the direction of testing optical performance and temperature control by electric means, which can solve the problems of easy change of optical glass coating optical parameters, inability to realize temperature control, and inability to eliminate the change of optical glass surface shape, etc. Achieve the effects of avoiding frost, high-precision temperature control, and reducing the impact of convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

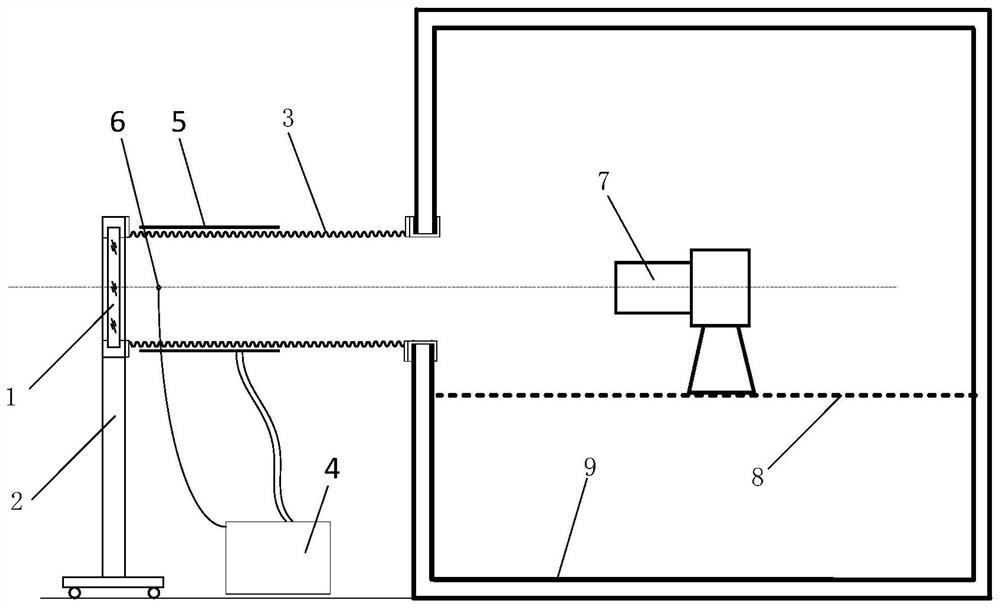

[0041] The invention provides a temperature control device for the optical glass window of a temperature test box, such as figure 1As shown, it includes optical glass 1, mounting bracket 2, metal bellows 3, temperature controller 4, temperature control circuit 5 and main temperature sensor 6; the optical glass 1 is embedded in the center of the optical glass flange, and the optical glass flange Installed on the mounting bracket 2 (rigid connection); the two ends of the metal bellows 3 have flanges, the flange at one end is connected to the optical glass flange, and the flange at the other end is connected to the temperature test box 9. The window flange of the metal bellows 3 is provided with a through hole on the side wall near the end of the optical glass 1, and a sealing plug is provided in the through hole to seal the opening position; the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com