heating device

A heating device and heating body technology, which is applied to electric heating devices, engine ignition, engine components, etc., can solve the problems of increased manufacturing cost, decrease in the temperature and heating rate of glow plugs, and decrease in heating temperature, so as to achieve manufacturing cost, Excellent mountability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

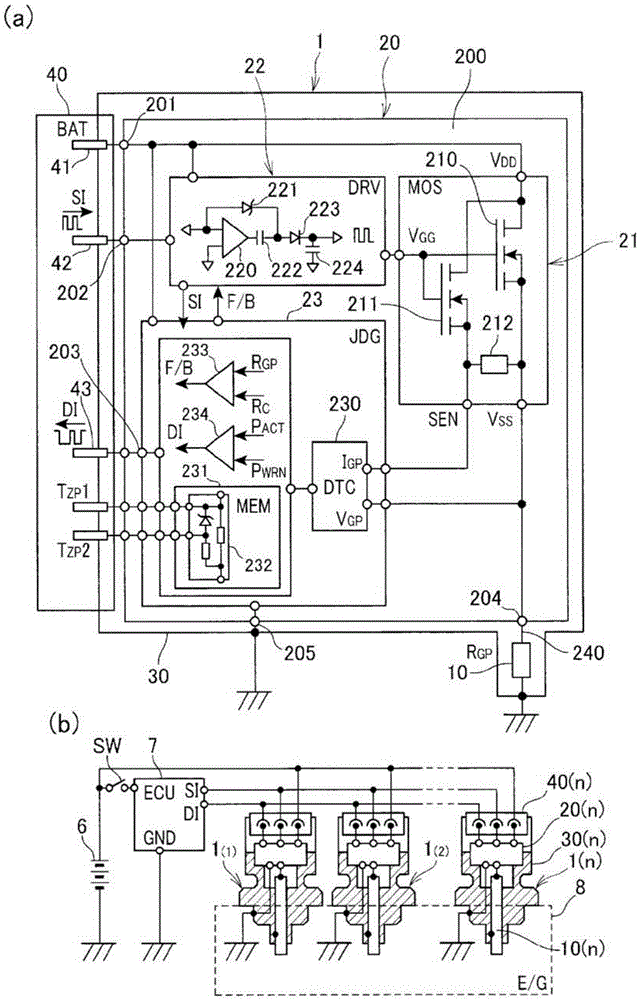

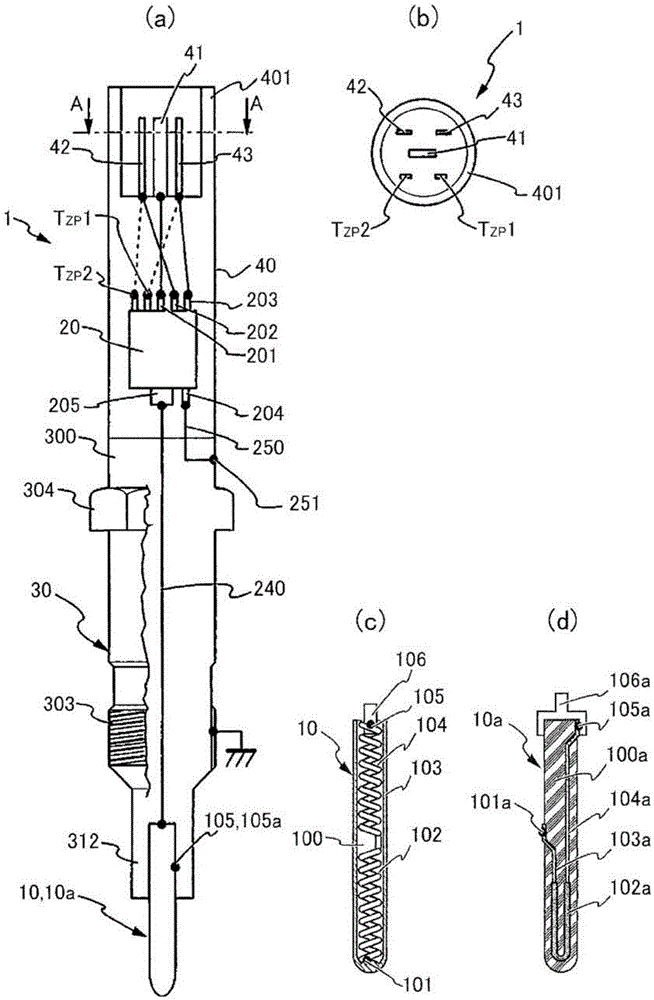

[0047] As the heat generating device in the embodiment of the present invention, a heat generating body 10 provided in each cylinder of an internal combustion engine (not shown) is used as a heat generating body, and an energization control module 20 for controlling energization from the power supply 6 to the heat generating body 10 is integrated. The controller-integrated glow plug 1 accommodated in the housing 30 .

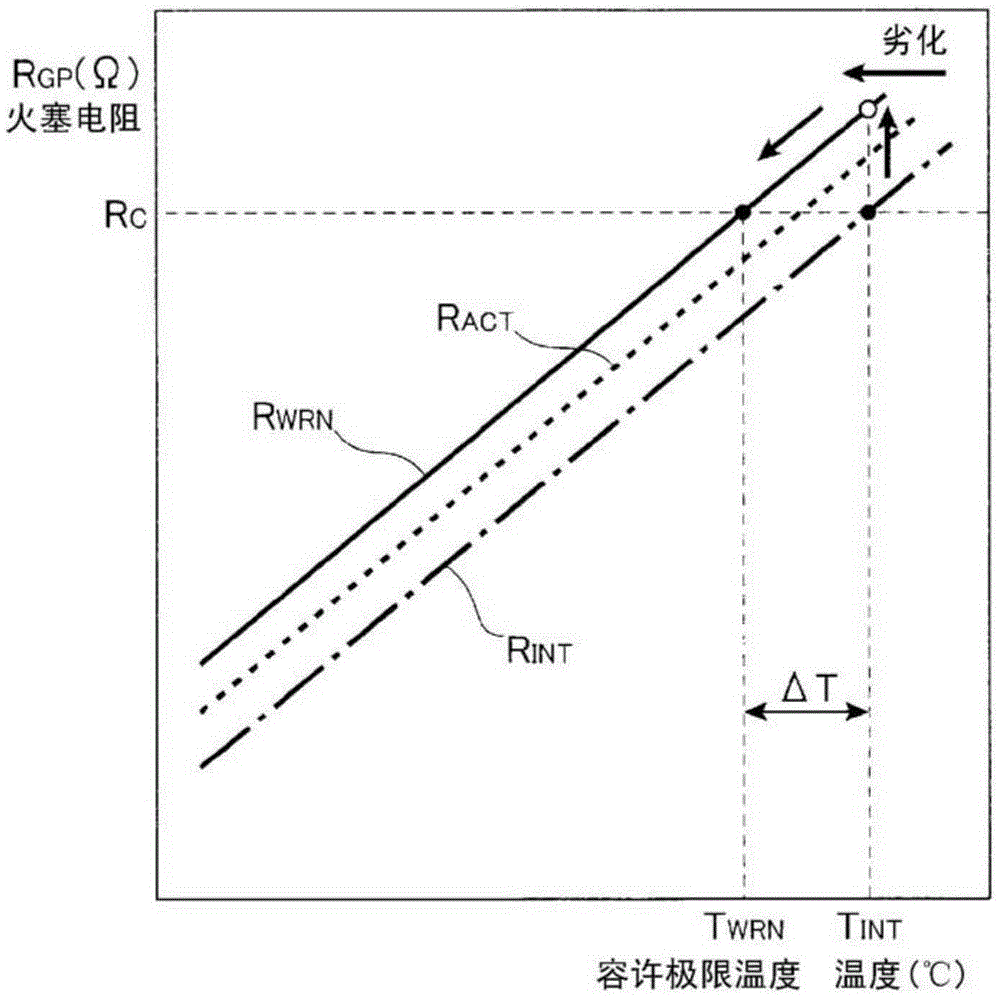

[0048] Such as figure 1 As shown, in the controller-integrated glow plug 1 of the present embodiment, it is equipped with: a heating element 10 that generates heat when energized, and its resistance value changes in a positive correlation with its own temperature change; an energization control module 20 , so that the resistor value R GP with the target resistor value R TRG In a consistent manner, the power supply from the power supply 6 to the heating element 10 is controlled; the reference resistance value storage unit 231 houses the heating element 10 integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com