Self-propulsion type concrete mixing ship

A mixing vessel, self-propelled technology, applied in the field of ships, can solve the problems of unfavorable maintenance and cleaning of powder waste, limited pouring height, and high transfer costs, so as to reduce transfer towing costs, reduce leasing or cost investment, The effect of preventing powder mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

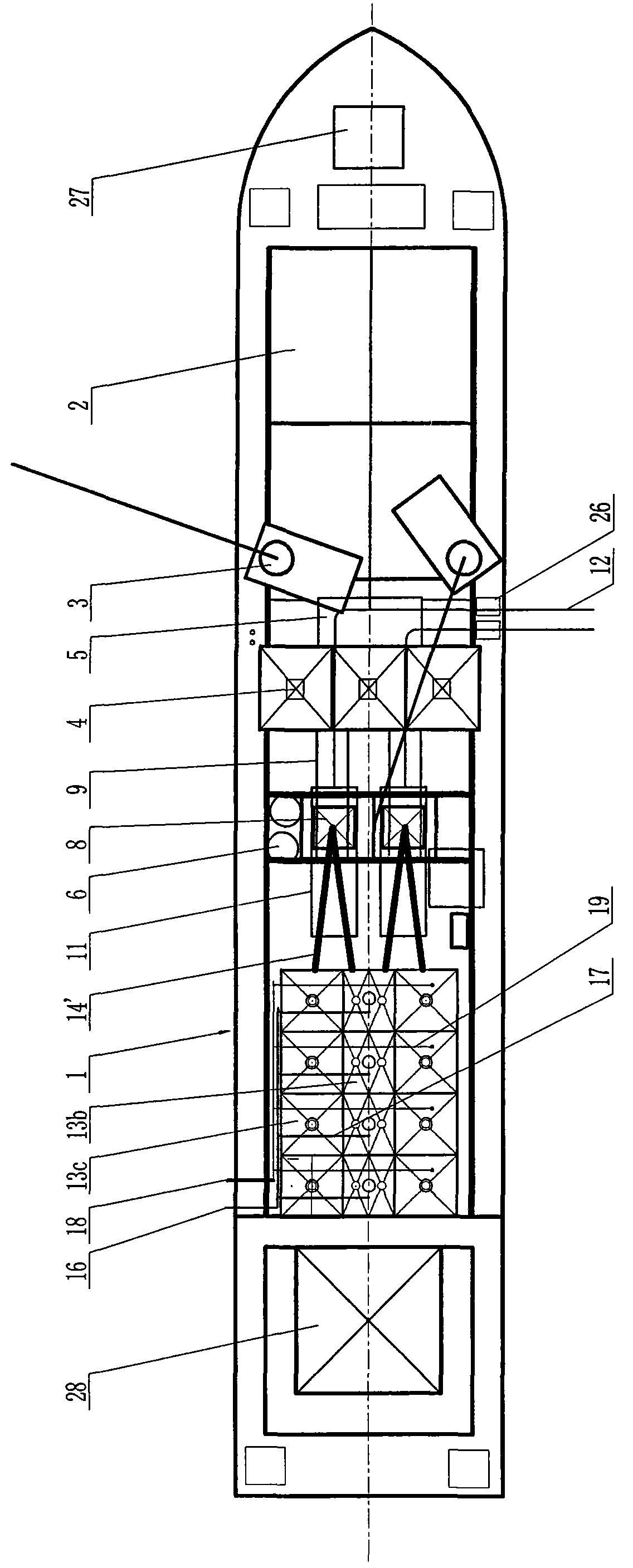

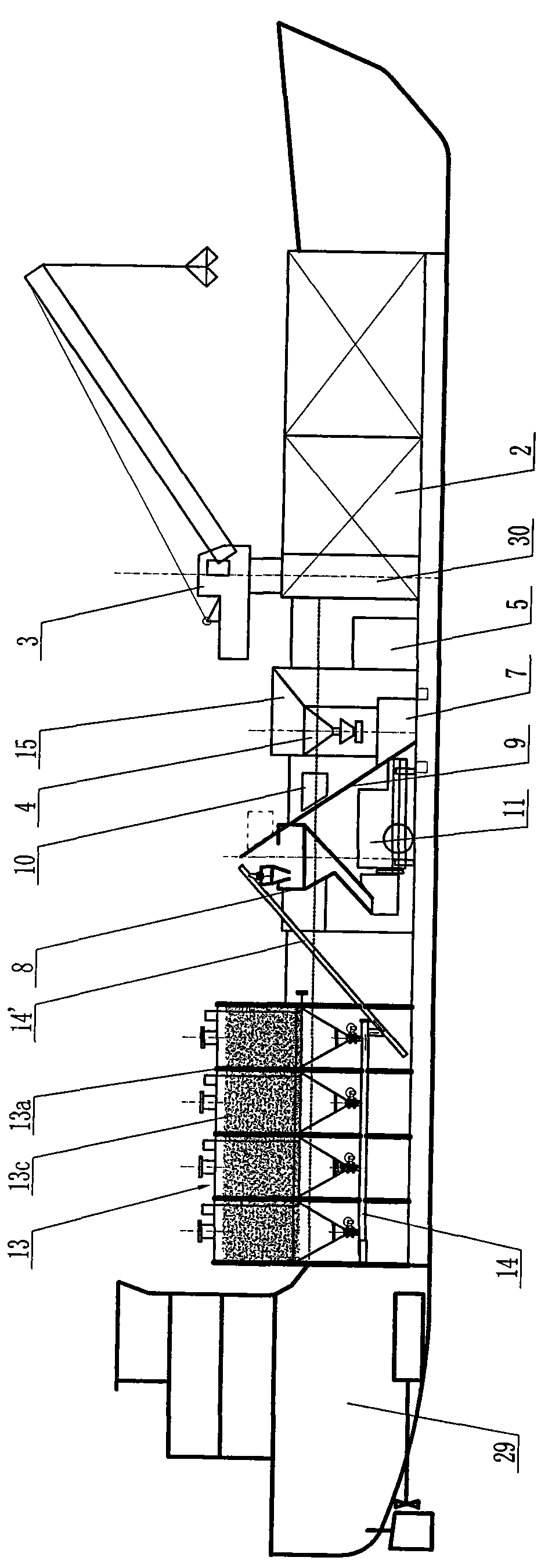

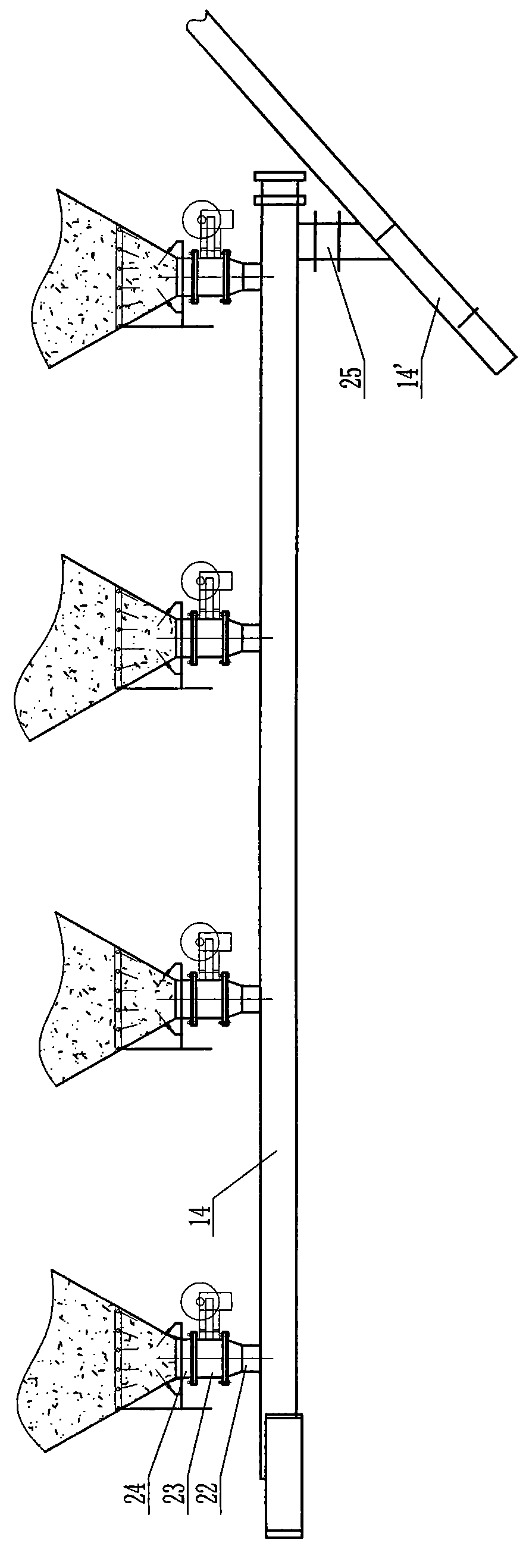

[0037]Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0038] like figure 1 , figure 2 As shown, the ship 1 is a deep warehouse cargo ship, the front end of the deep warehouse cargo ship is the front engine room 27, the rear end of the deep warehouse cargo ship is the crew living area 28, and the crew living area 28 is set below the power engine room 29. The power system equipped with the Shencang cargo ship is the same as the existing structure, and will not be repeated here. Between the front engine room 27 and the power engine room 29 is the inner warehouse of the deep warehouse cargo ship. The front part of the inner warehouse of the deep warehouse cargo ship is divided into four independent aggregate bins 2 by a plurality of partitions. These four aggregate bins 2 are cuboid cuboid cavities with upper openings and equal volumes for storing yellow sand or gravel.

[0039] from figure 1 , figure 2 It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com