Epoxy/POSS/carbon fiber nanometer composite material for light sports equipment and preparation method thereof

A nano-composite material and carbon fiber technology, applied in the field of nano-composite materials, can solve the problems of difficult toughening and reinforcement, and achieve the effects of improving shock absorption, shock absorption and vibration damping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

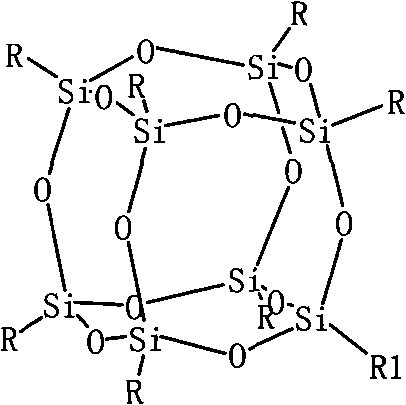

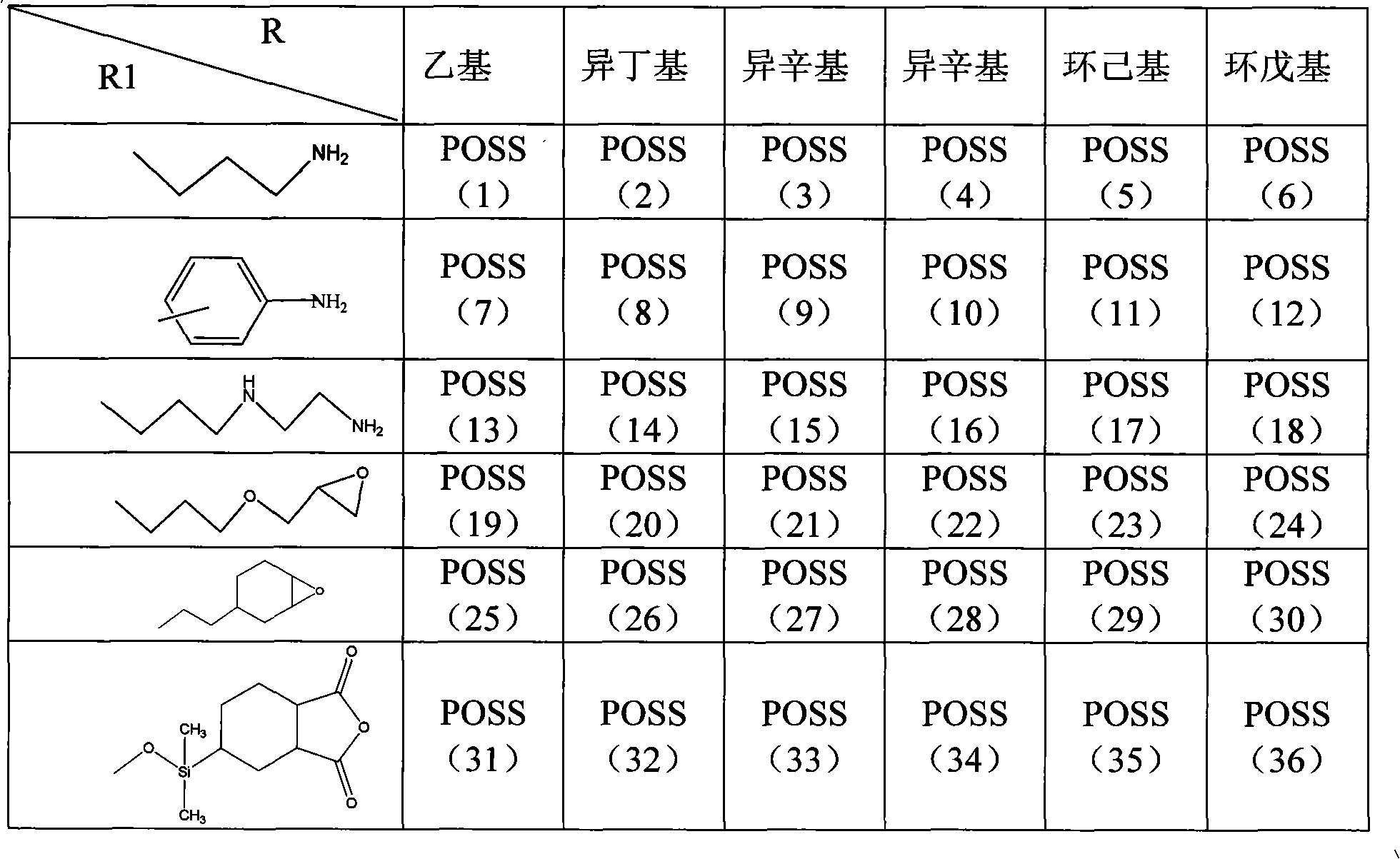

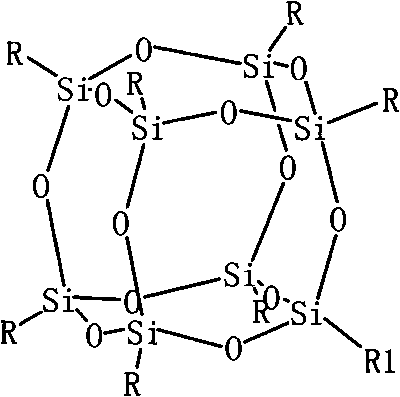

Image

Examples

Embodiment 1

[0031] 1) 10 mmol of epoxy resin Denacol EX251 (bisphenol S-type glycidyl ether) + 1 mmol of POSS (2), react at 110° C. for 3 hours to obtain a mixed solution containing modified POSS, and set aside.

[0032] 2) Mix the modified POSS obtained in step 1 with the butanone solution of Denacol EX251 and triethylenetetramine in an equal stoichiometric ratio, control the viscosity of the solution at room temperature to 1 kcps, and set aside.

[0033] 3) After impregnating the carbon fibers in the above solution, wind them on the release paper tube according to the designed geometric network. After the solvent evaporates, cut the paper tube to obtain the epoxy-coated carbon fiber mesh surface.

[0034] 4) The epoxy-coated carbon fiber grid surface obtained in step 3 is curled and designed into a tennis racket shape and placed in a mold. After curing and demoulding, a tennis racket made of epoxy / POSS / carbon fiber nanocomposite is obtained. Wherein the POSS content is 1 wt%, and the ca...

Embodiment 2~6

[0037] The POSS (2) of step 1 is changed into POSS (1), POSS (3), POSS (4), POSS (5), POSS (6) respectively; All the other are with embodiment 1. The mechanical properties of the prepared epoxy / POSS / carbon fiber nanocomposites are shown in Table 2.

Embodiment 7

[0039] 1) Use 5mmol epoxy resin Epikote825 (bisphenol A glycidyl ether) + 1mmol POSS (11), react at 170°C for 10h to obtain a mixed solution containing modified POSS. spare.

[0040] 2) Prepare a methyl ethyl ketone solution of the component Epikote825+4,4-diaminodiphenylmethane+modified POSS (equal stoichiometric ratio) obtained in step 1, with a room temperature viscosity of 10 kcps. spare.

[0041] 3) Wrap the carbon fiber impregnated with the solution in step 2 on the paper tube according to the designed geometric network, and after the solvent evaporates, cut the paper tube to obtain an epoxy-coated carbon fiber mesh surface.

[0042] 4) The epoxy-coated carbon fiber grid surface obtained in step 3 is curled and designed into a product form, placed in a mold, cured, and demoulded to obtain an epoxy / POSS / carbon fiber nanocomposite material. After curing and demoulding, an epoxy / POSS / carbon fiber nanocomposite material is obtained, wherein the POSS content is 5 wt%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com