Digital electrohydraulic control system of steam turbine with isolated network operation

A control system, digital electro-hydraulic technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of low stability, difficult to isolate small network frequency stability, system stability decline, etc., to ensure stability, The effect of improving continuous control ability and quick response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

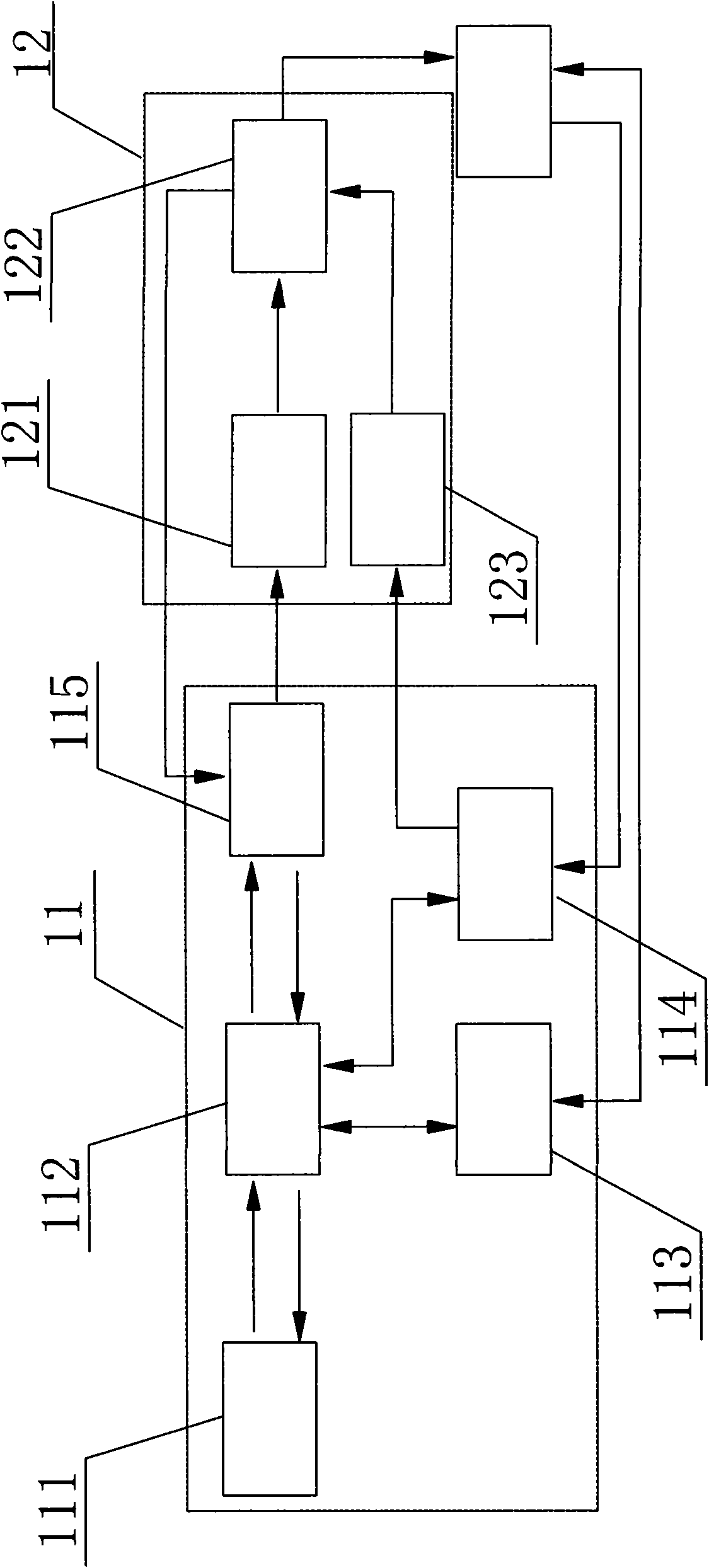

[0013] figure 1 It is a structural block diagram of a typical steam turbine digital electro-hydraulic control system in the prior art. In the figure: the virtual box 11 is the electronic control hardware part, the virtual box 12 is the hydraulic servo actuator part, and the electronic control hardware part 11 includes the man-machine interface part 111, control Unit 112 , input / output module 113 , overspeed protection component 114 and servo control module 115 ; hydraulic servo actuator part 12 includes electro-hydraulic servo valve 121 , oil motor 122 and OPC device 123 .

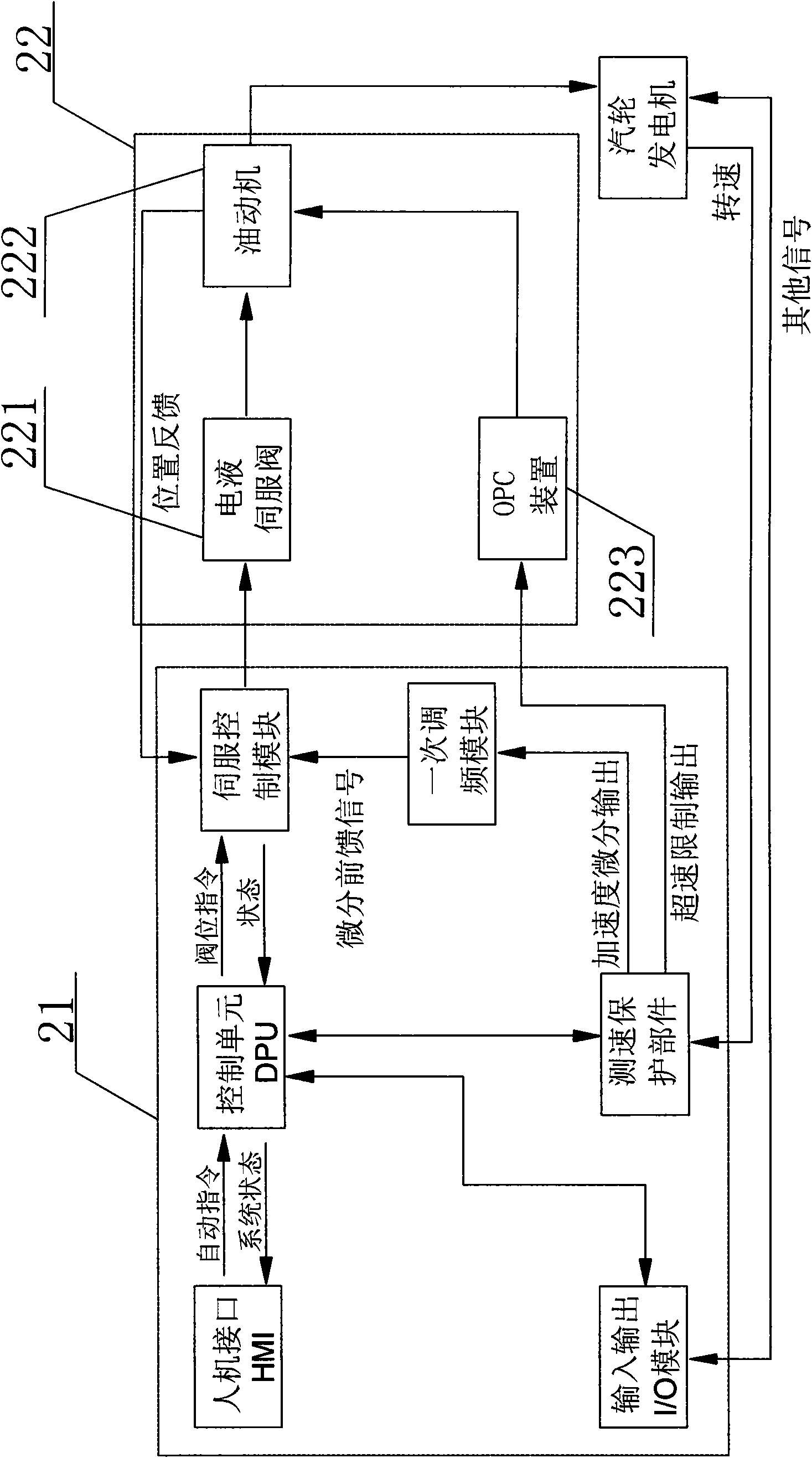

[0014] figure 2 The structural block diagram of the steam turbine digital electro-hydraulic control system of the present invention is composed of an electronic control hardware part 21 and a hydraulic servo actuator part 22 .

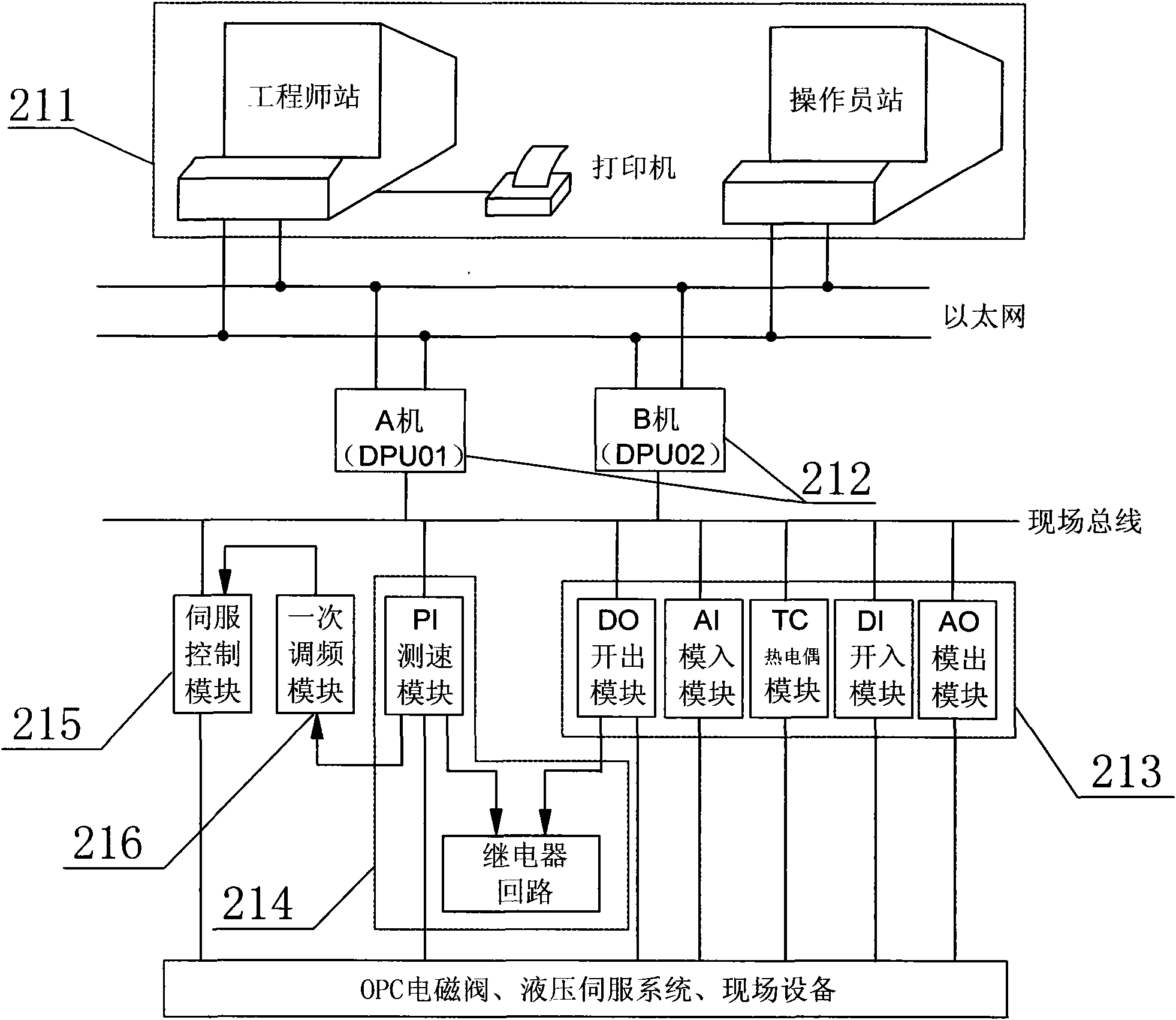

[0015] The computer control part 21 such as image 3 As shown: i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com