Motor, compressor and air conditioning system having the same

A technology of compressors and compression mechanisms, applied in compressors, irreversible cycle compressors, machines/engines, etc., can solve problems such as slow synchronous speed of single-phase induction motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

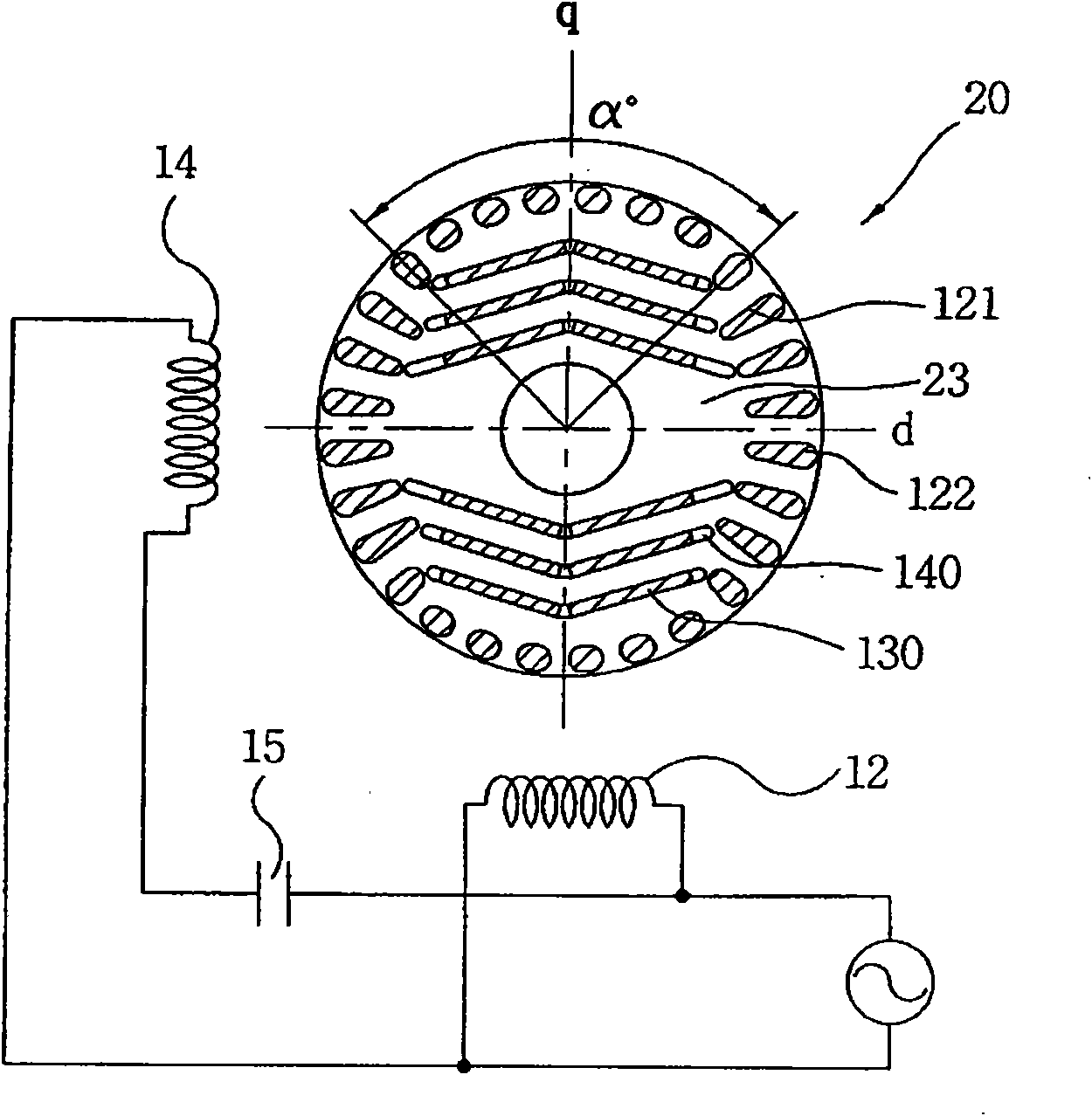

[0098] In the following, reference will be made to the attached Figure 3 to Figure 15 A preferred embodiment of the electric machine according to the invention is set out in detail. For the sake of brevity and convenience of explanation, it will be described that an inner rotor type motor is provided which rotates inside a stator, but the motor of the present invention is not limited to the inner rotor type motor.

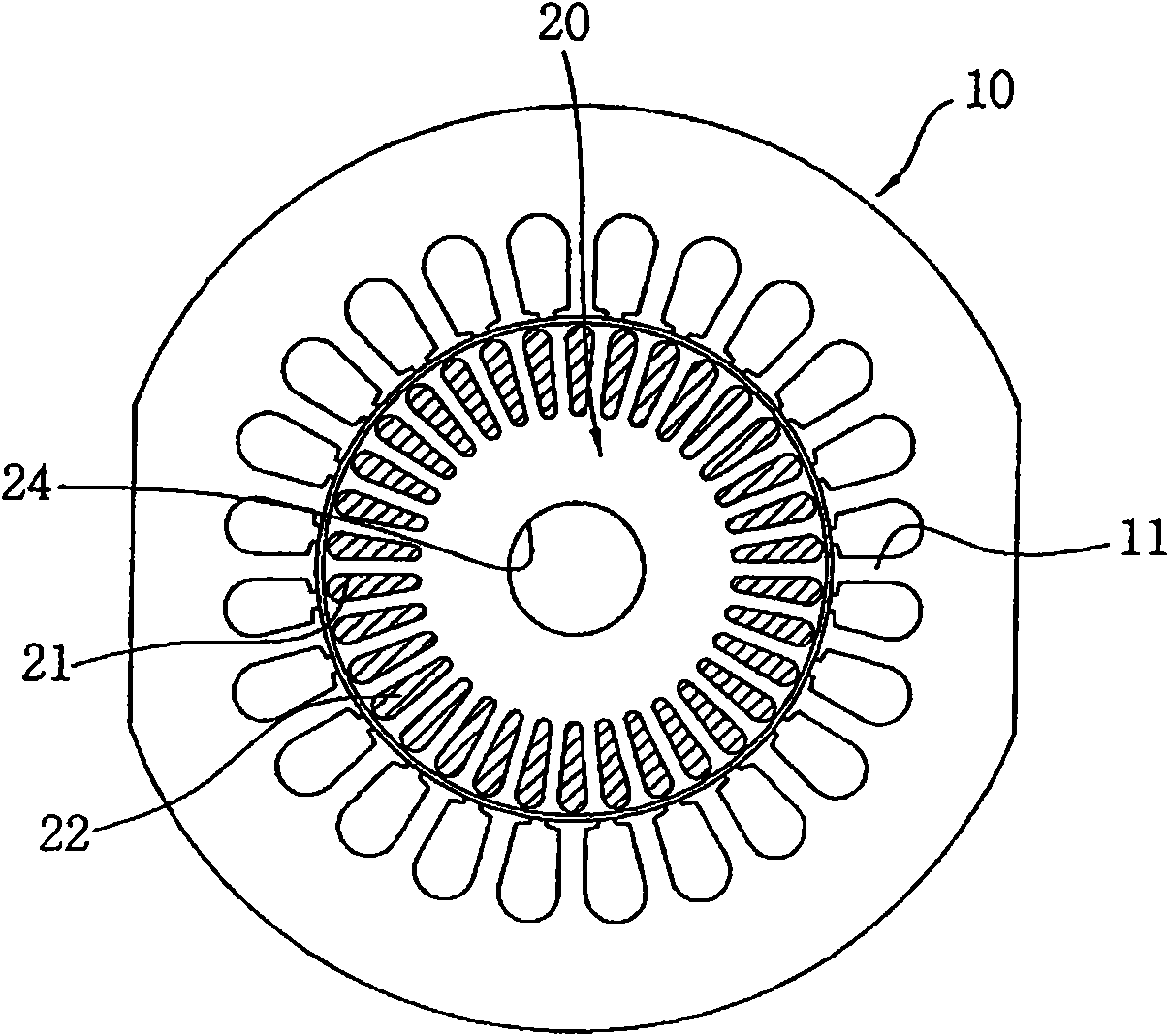

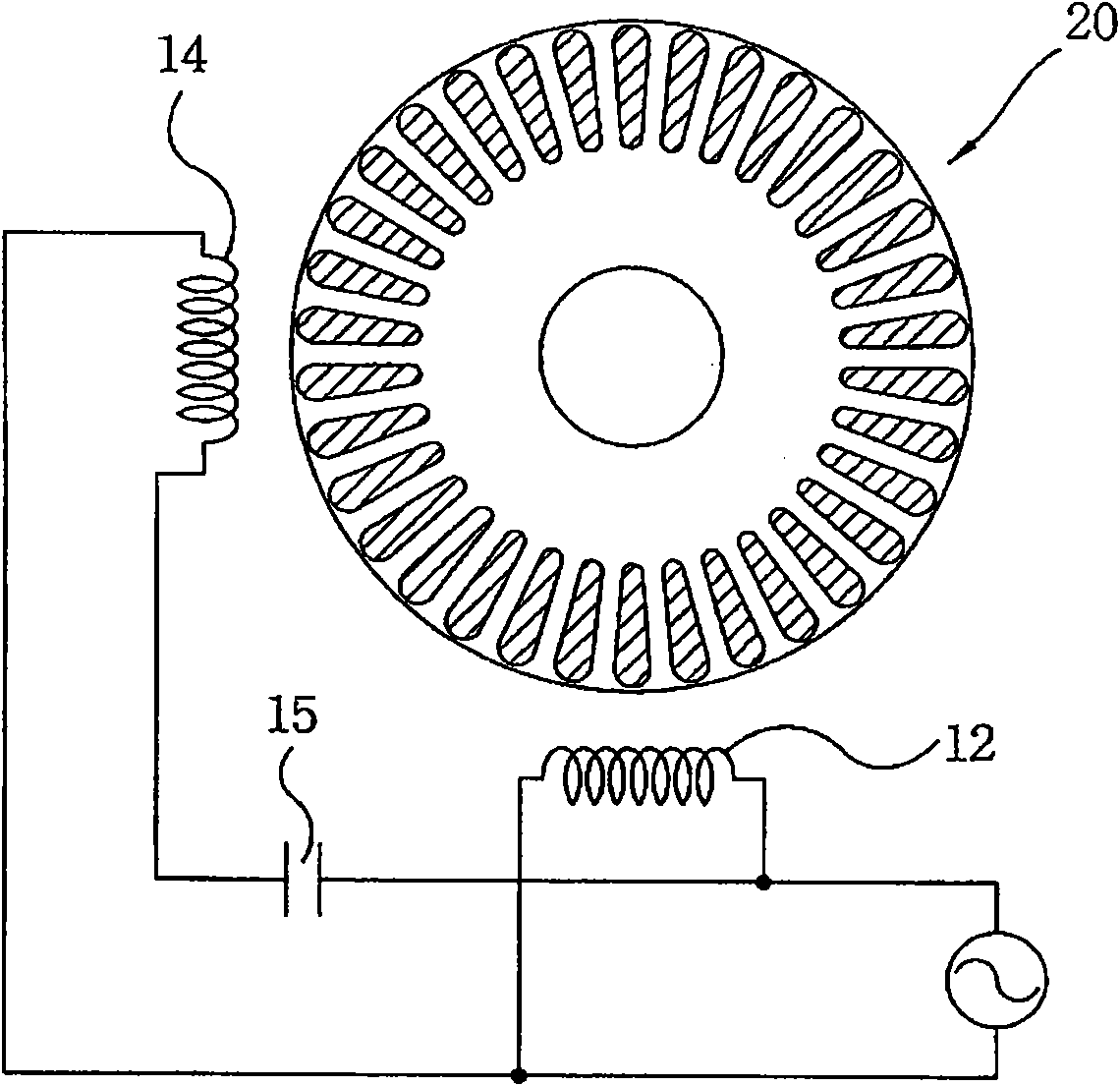

[0099] The motor according to the present invention is constructed by the same method as conventional induction motors in the prior art, wherein the rotor 120 [w9] starts running by induction torque. That is, if image 3 As shown, the motor adopts the structure of an induction motor, including a rotor 120 having slots 121 and conductive rods 122, a stator coil 112 [w10] and a stator coil 114 [w11] (hereinafter referred to as "coils") for rotation of the motor , and capacitor 115 [w12]. Therefore, any description below will not detail the same structure between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com