Large-power LED light source module

A LED light source and high-power technology, which is applied in the field of high-power LED light source modules, can solve problems such as heat accumulation, and achieve the effects of good sealing and waterproof performance, reasonable structure, waterproof and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

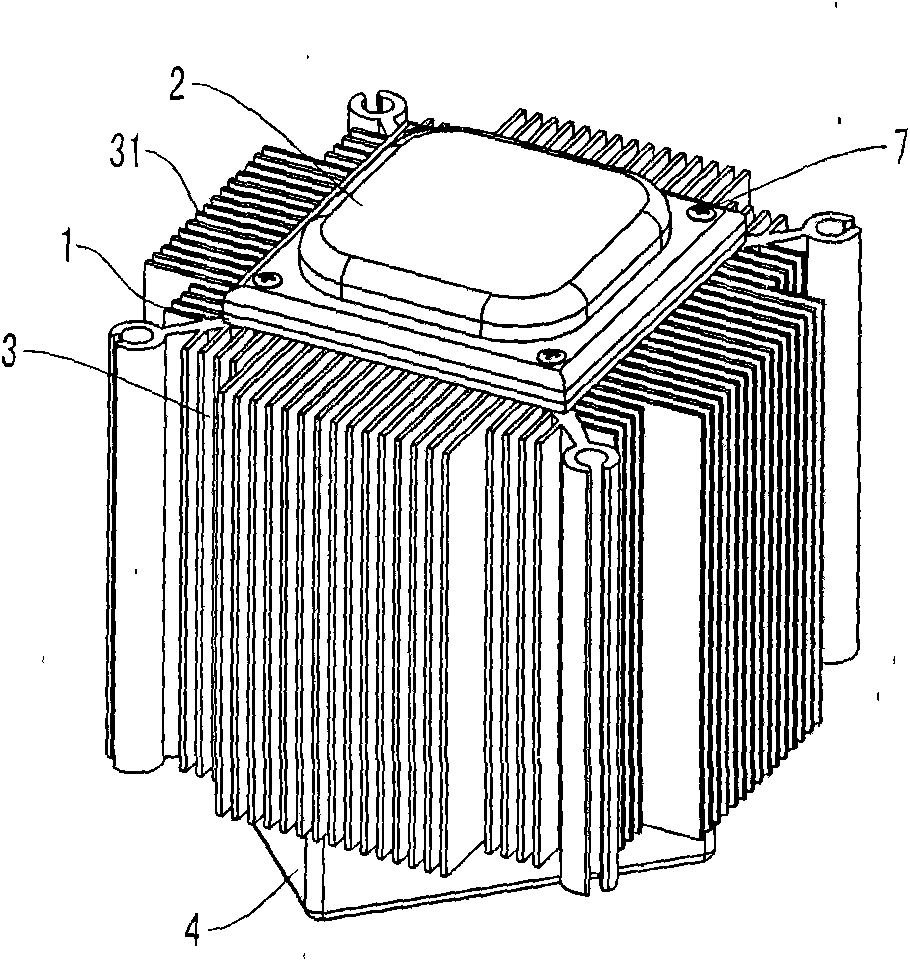

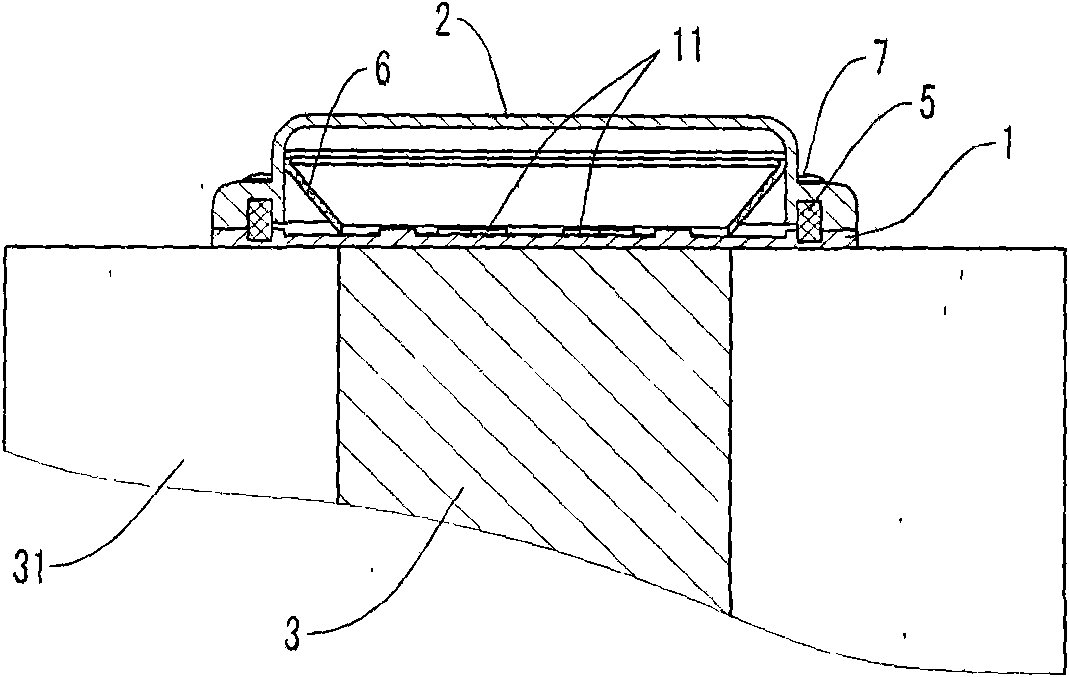

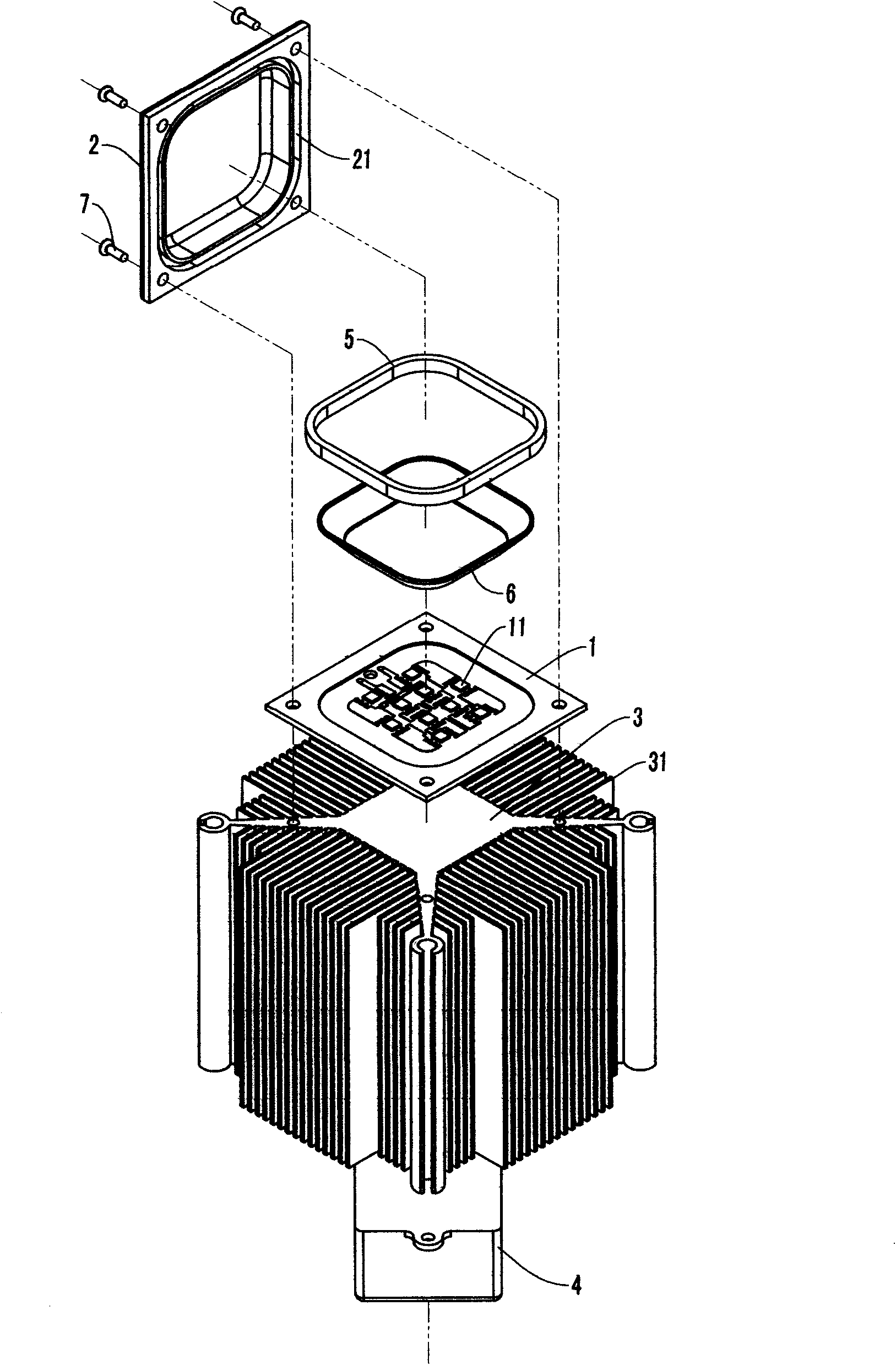

[0017] refer to figure 1 , figure 2 and image 3 The high-power LED light source module includes an aluminum substrate 1 welded with a high-power LED illuminant 11, a transparent lampshade 2 fixed on the front of the aluminum substrate 1, and a radiator 3 fixed on the back of the aluminum substrate 1, and the LED driver 4 is fixed on the radiator 3 On the other end, the LED driver 4 is electrically connected to the aluminum substrate 1 through wires to provide control and working power for the LED illuminant 11 . Corresponding screw holes are provided on the transparent lampshade 2, the aluminum base plate 1 and the radiator 3, and the three are locked together by a set of screws 7, which simplifies the module assembly process.

[0018] In the structure of this example, a plurality of LED luminous bodies 11 are welded on the aluminum substrate 1 to make it reach a certain rated power and light intensity and meet commercial requirements. For this reason, higher requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com