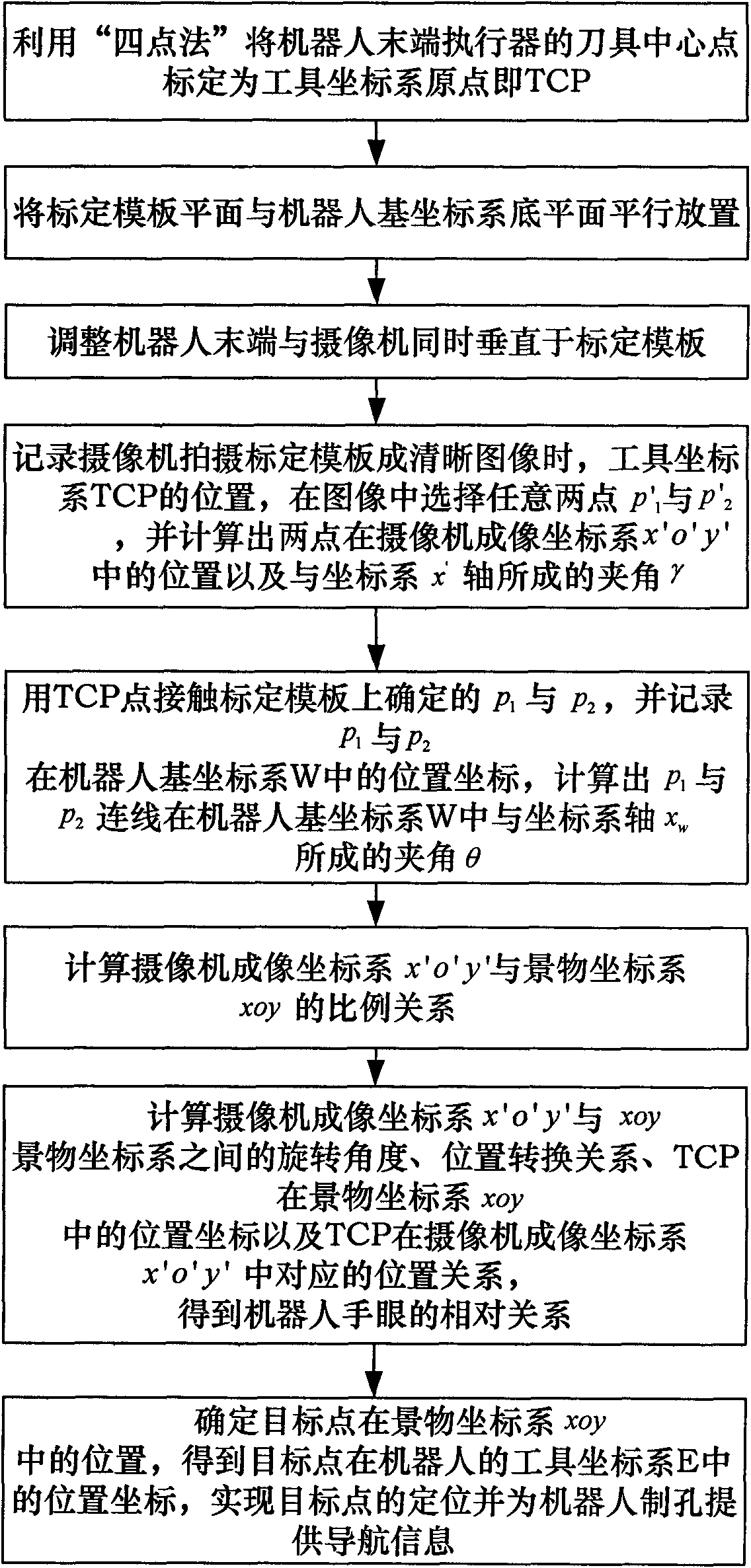

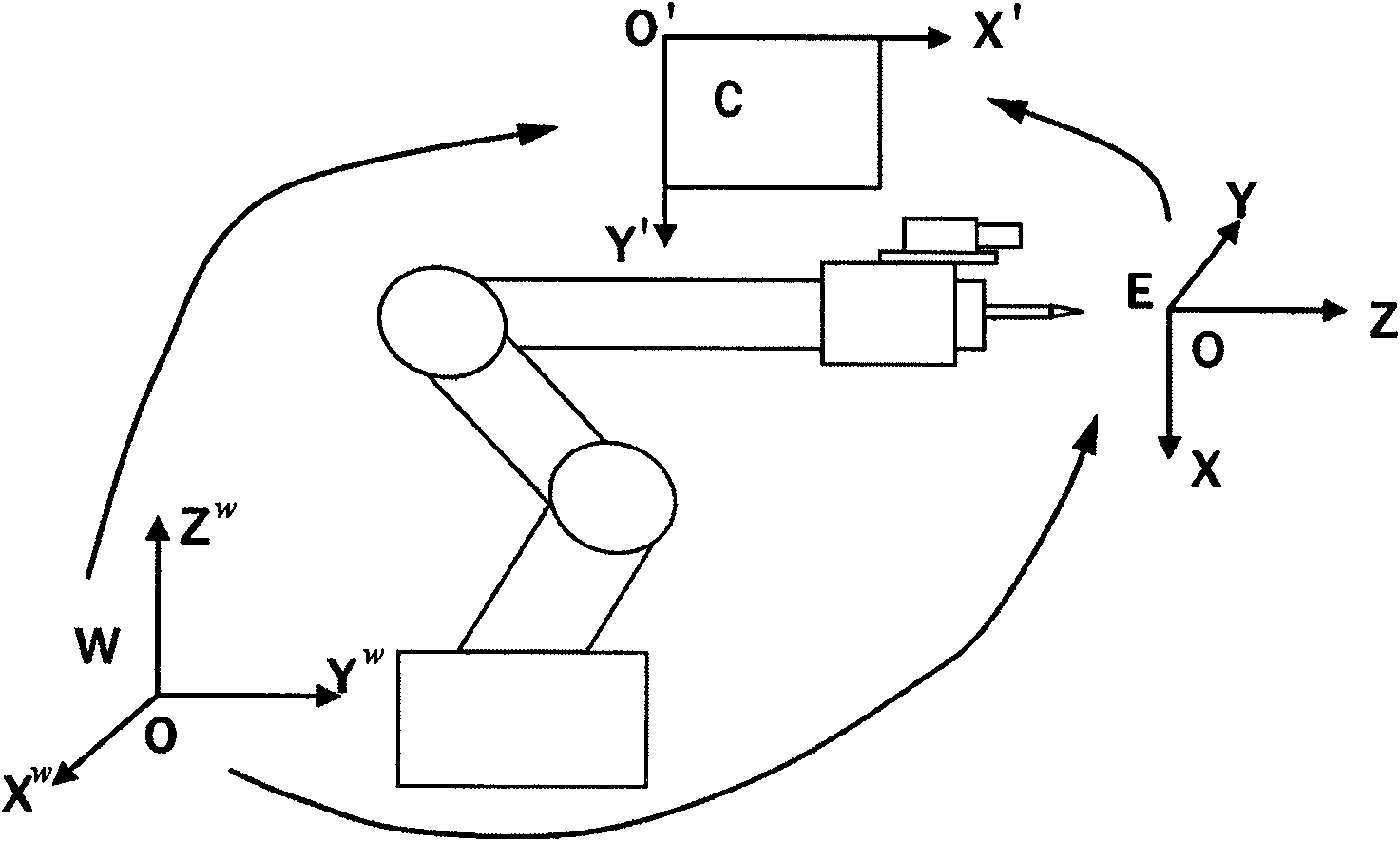

Hand-eye vision calibration method for robot hole boring system

A robotic hole-making, hand-eye vision technology, applied in instruments, image data processing, measuring devices, etc., can solve problems such as inapplicability to on-site calibration, affecting calibration accuracy, and complex process, achieving high practical value, simple calibration process, and calculation. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

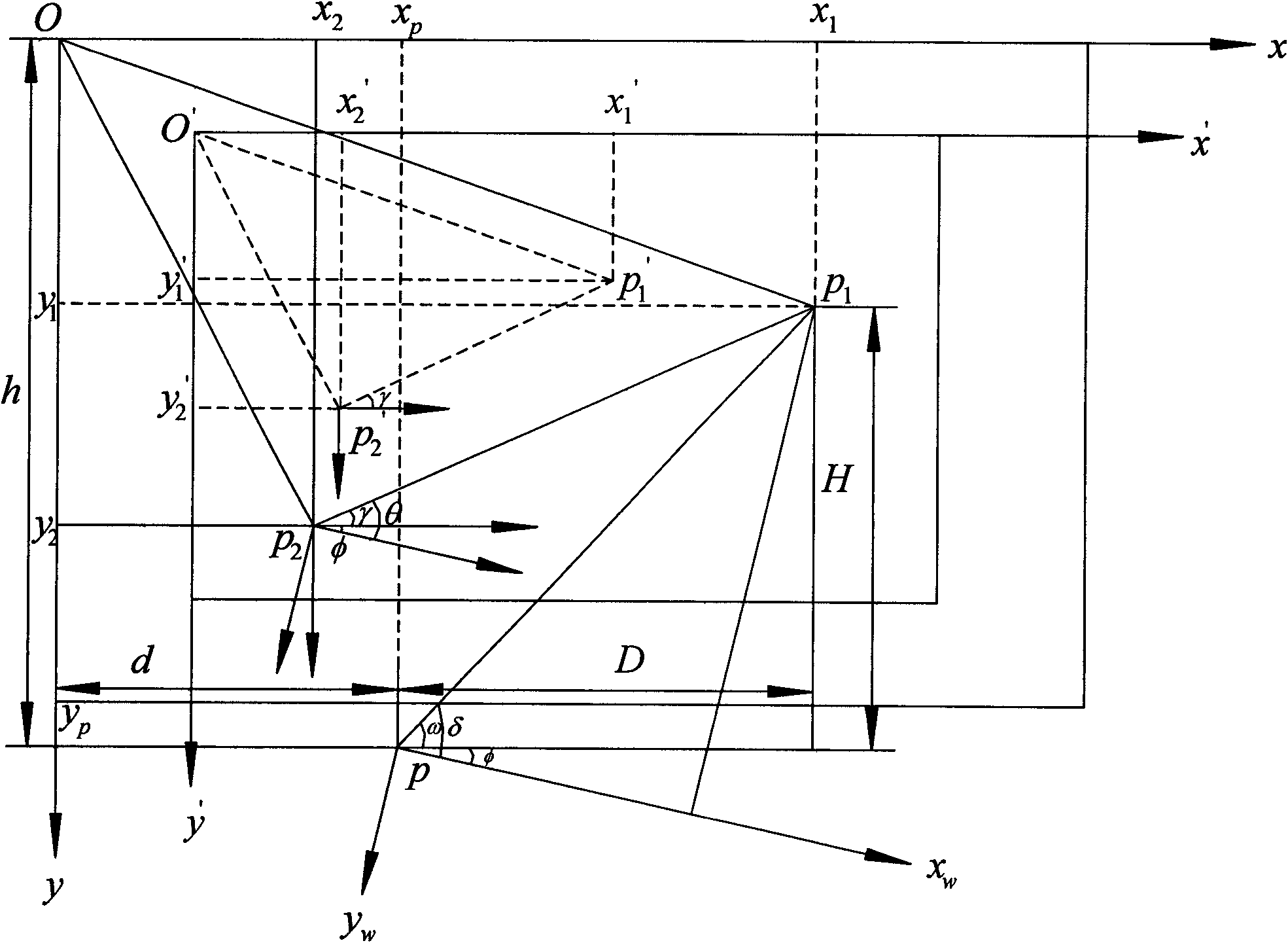

Method used

Image

Examples

Embodiment

[0093] Apply the method described in the present invention, at first carry out hole making with end effector to obtain the actual position coordinates of the hole, then use camera to shoot, carry out positioning to obtain the positioning coordinates of the hole and calculate the positioning error, the data are as shown in Table 1:

[0094] Table 1 Positioning error data table

[0095] Group

No

actual coordinates

Positioning coordinates

Δx / mm

Δy / mm

positioning error

E / mm

1

(1168.24,-5.19)

(1168.25,-5.16)

0.01

0.03

±0.03

[0096] 2

(1176.87,-81.80)

(1176.99,-81.77)

0.12

0.03

±0.12

3

(1132.69,-35.58)

(1132.87,-35.44)

0.18

0.14

±0.23

4

(1086.87,-8.79)

(1087.01,-8.68)

0.14

0.11

±0.18

5

(1135.85,-66.08)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com