Metalworking fluid and metalworking method

A technology of metal processing and oil agent, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of worrying about influence and insufficient anticorrosion effect, and achieve the effect of improving anticorrosion performance, saving resources and excellent anticorrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

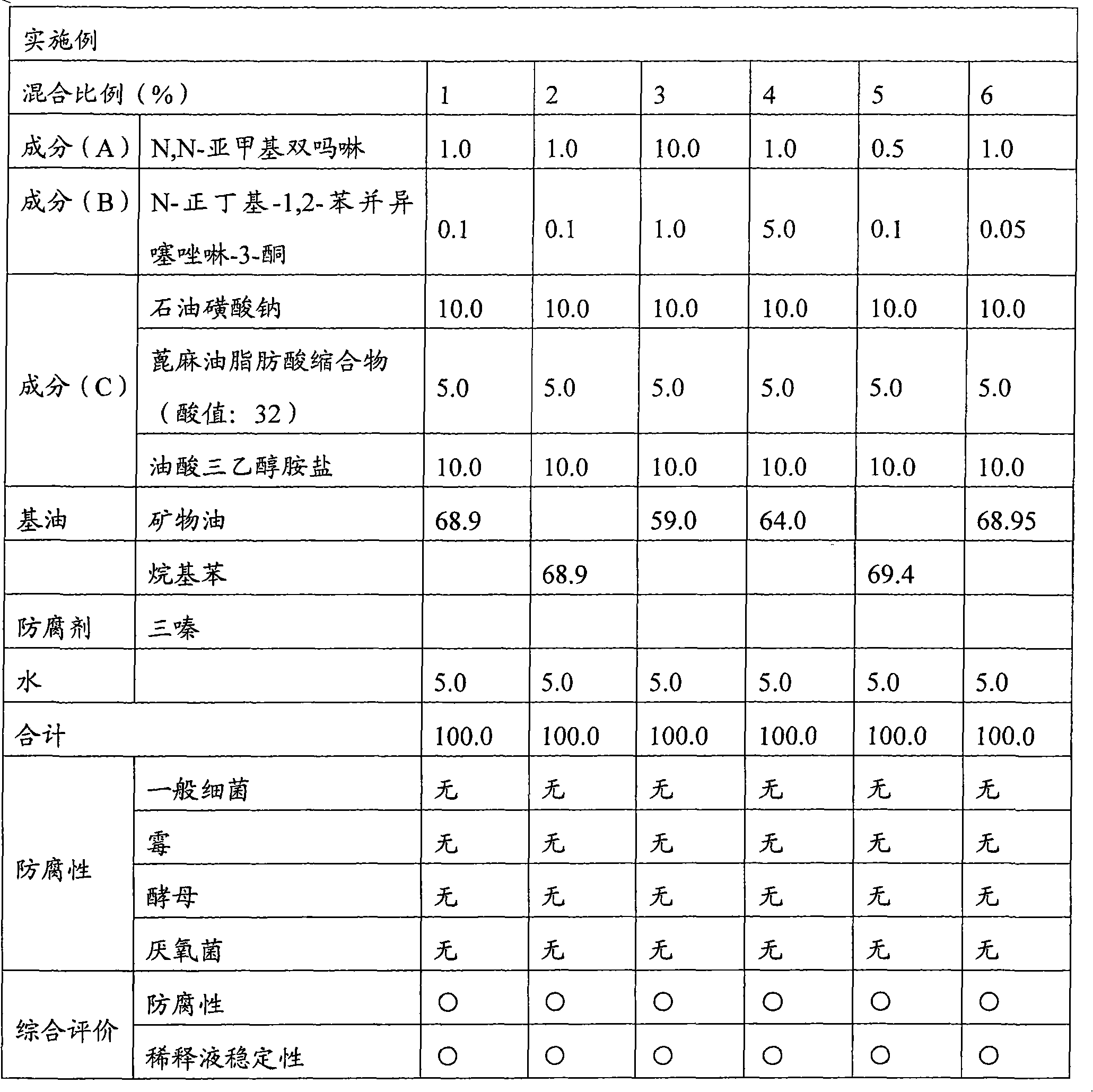

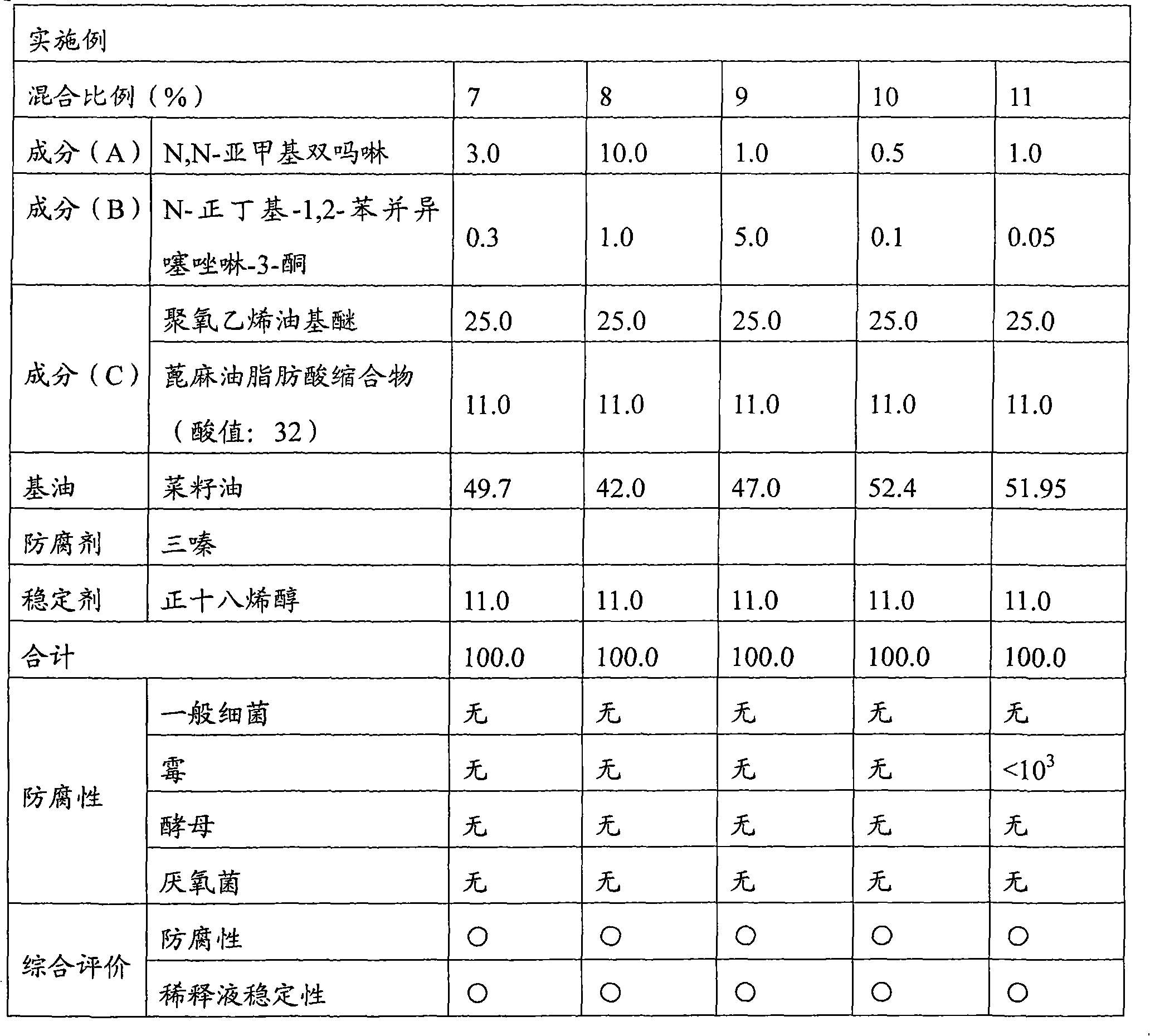

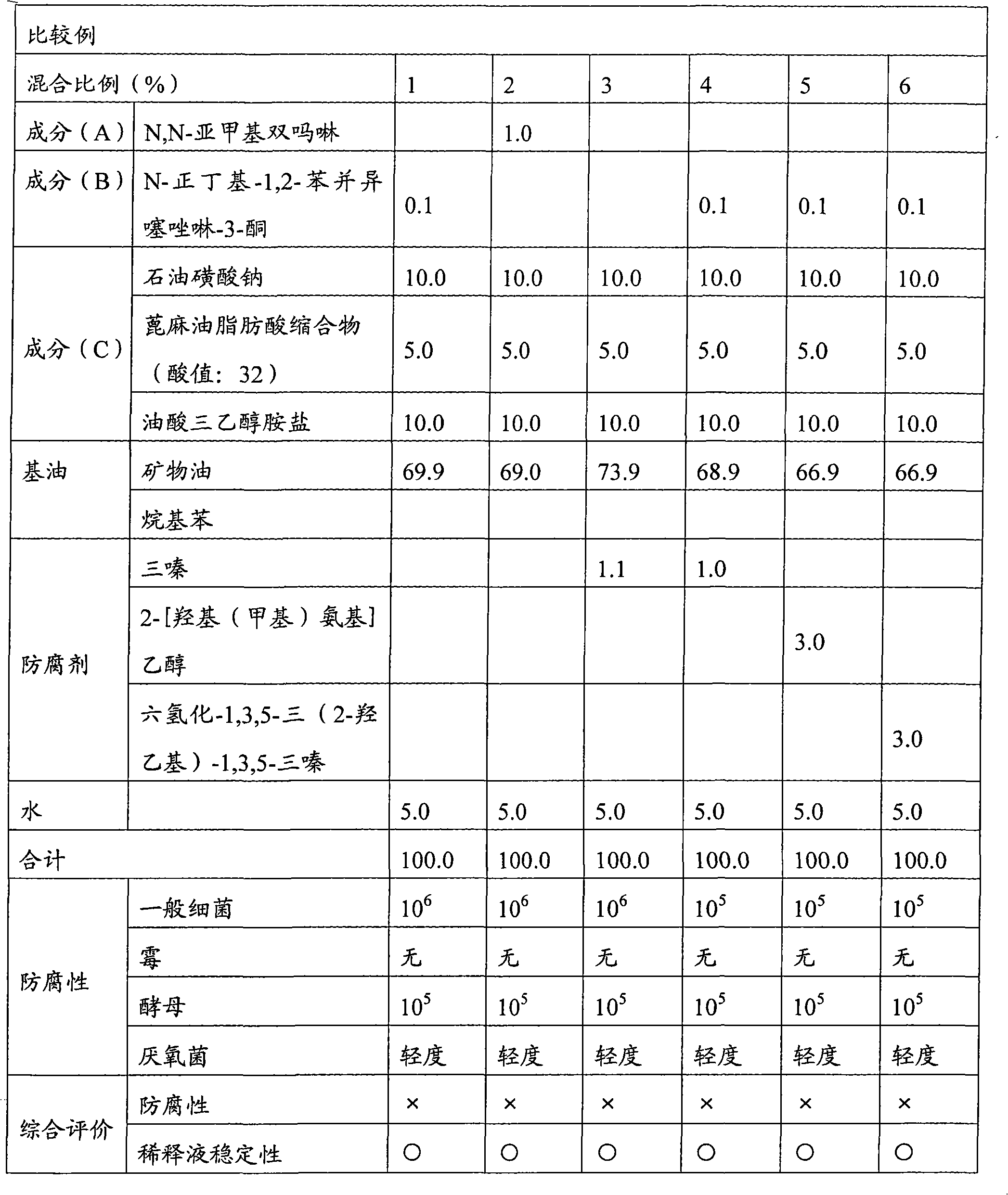

[0040] For each oil agent for metalworking shown in Tables 1 to 4, the anticorrosion test was evaluated by the following method.

[0041] The oils shown in Tables 1 and 3 are water-soluble metalworking oils using mineral oil or synthetic base oil (alkylbenzene), and the oils shown in Tables 2 and 4 are natural base oils (rapeseed oil) Water-soluble metalworking oil.

[0042] Anti-corrosion test

[0043] In the liquid 100ml that each oil agent is diluted to 2% by mass with sterilized water, add 10ml of the following spoilage bacteria liquid ( * 1) After vibrating culture at 30°C for 2 weeks, the number of viable bacteria was measured.

[0044] * 1 spoilage liquid

[0045] Emulsion-type cutting fluid with deterioration of corruption 10.0% by mass

[0046] Tryptic Soy Broth 1.0% by mass

[0047] Glucose-peptone medium 1.0% by mass

[0048] Sterilized water 88.0% by mass

[0049] As the spoilage solution, the spoilage bacteria solution of the above-mentioned mixture cultur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com