Transportation manipulators of railway truck body

A technology of railway freight cars and manipulators, which is applied in the directions of cranes, cranes, transportation and packaging of trolleys, can solve the problems of inconvenience, insecurity, low efficiency, etc., and achieve the effect of reducing labor intensity of workers and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

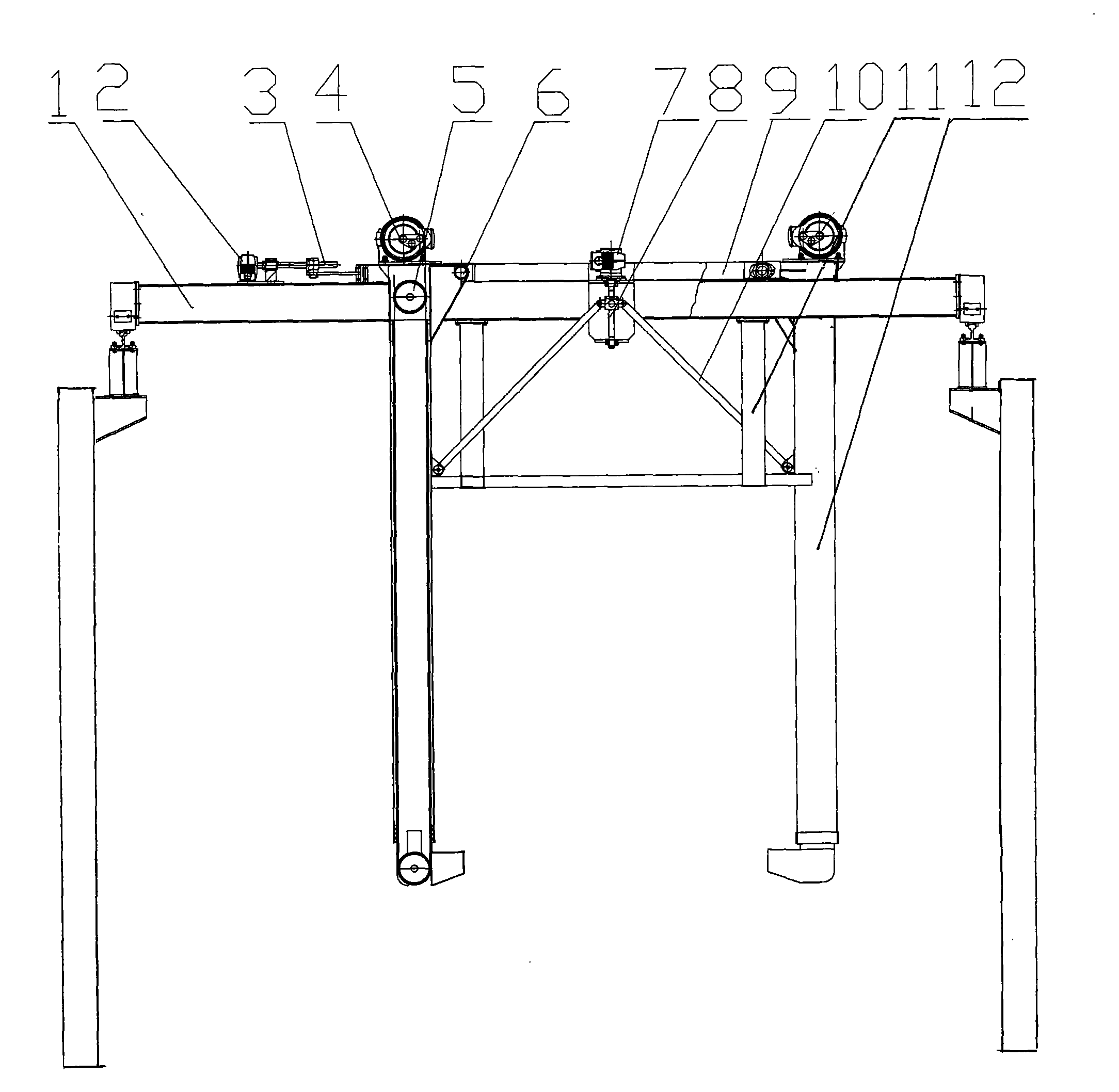

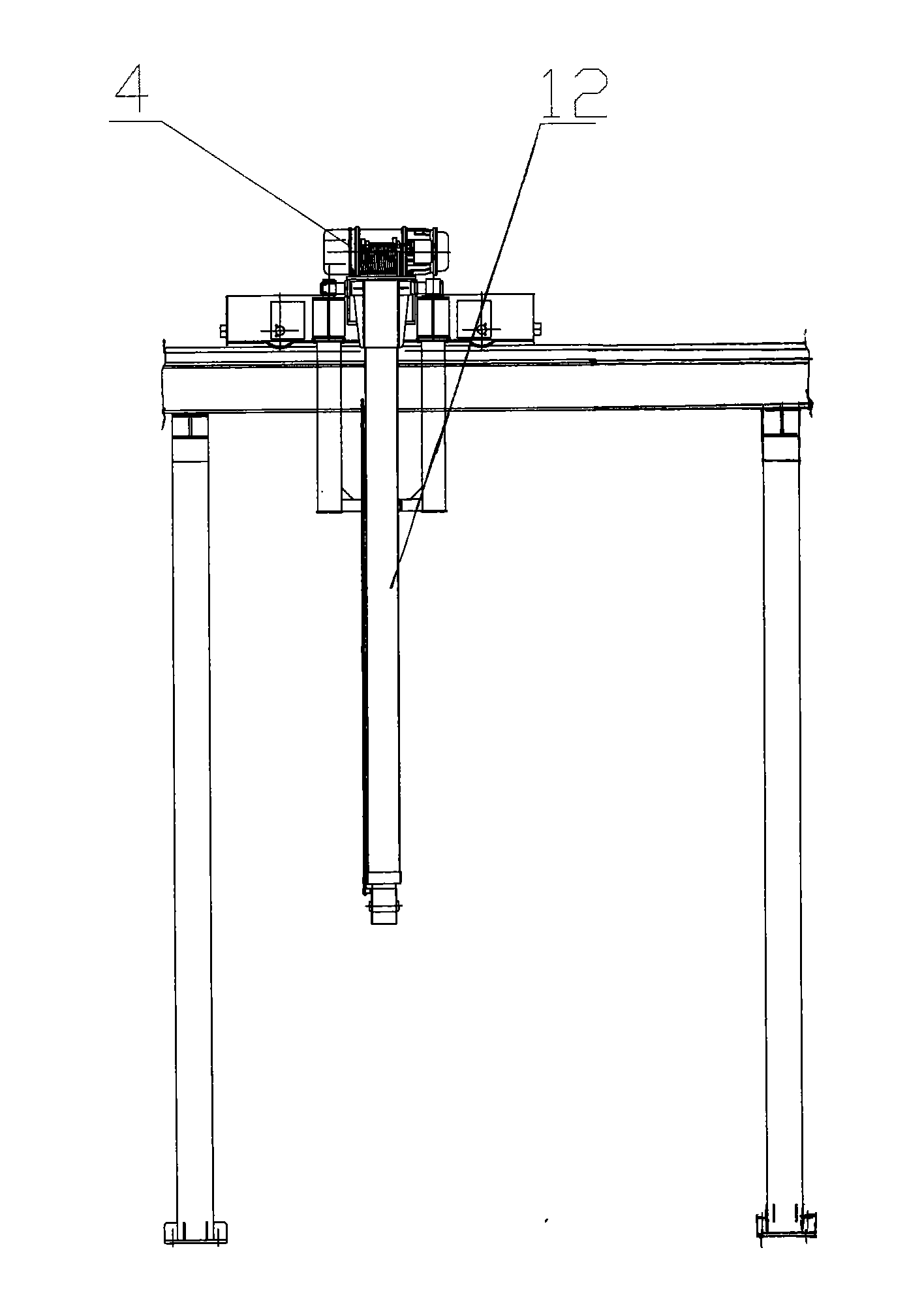

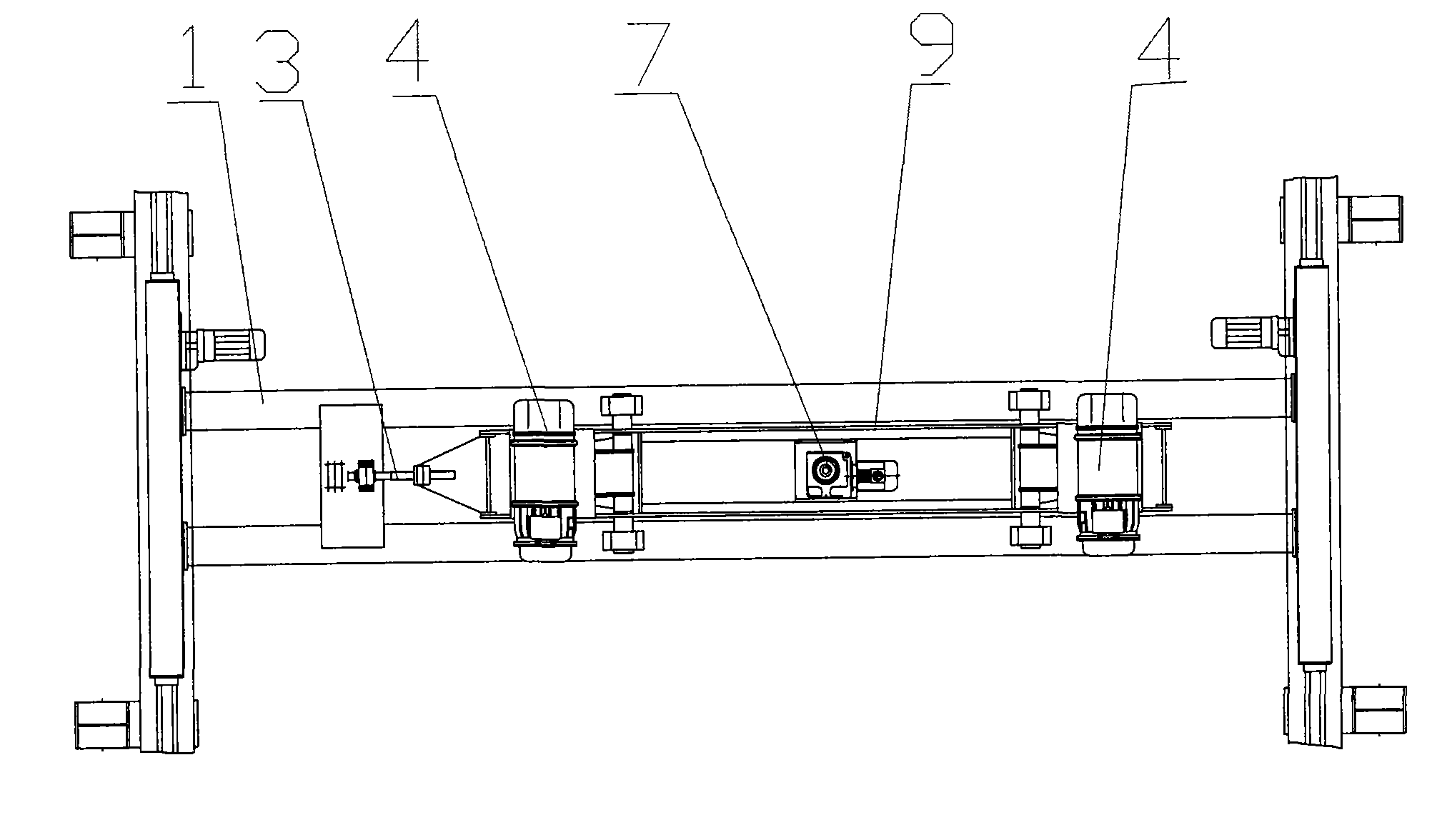

[0012] See figure 1 A traverse frame 9 is set on the moving crossbeam of the crane 1, and a lead screw auxiliary adjustment device 3 is arranged at one end of the traverse frame 9. The screw pair adjustment device 3 is driven by the reducer 2 . The two ends of the traversing frame 9 are connected to a pair of manipulators 12 through the hinge shaft 6. The manipulator 12 is provided with an outer sleeve 13, and the inner sliding sleeve 15 that moves up and down is assembled in the outer sleeve 13. The lower end of the inner sliding sleeve 15 is connected to the hook 16, and the upper end of the outer sleeve 13 The pulley 5-1,5-2 of assembly pulley block is respectively assembled with the lower end of inner sliding sleeve 15, and pulley block is driven by electric hoist 4. A positioning frame 11 and an outwardly stretching driving device are arranged inside a pair of manipulators 12. The positioning frame 11 is connected to the traverse frame 9, and its two ends can limit the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com