Device and method for etching optical glass

An optical glass and etching device technology, applied in the field of etching devices, can solve problems such as regrinding, uneven etching, and poor glass uniformity, and achieve the effects of increasing etching rate, reducing mechanical strength and physical property restrictions, and reducing stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

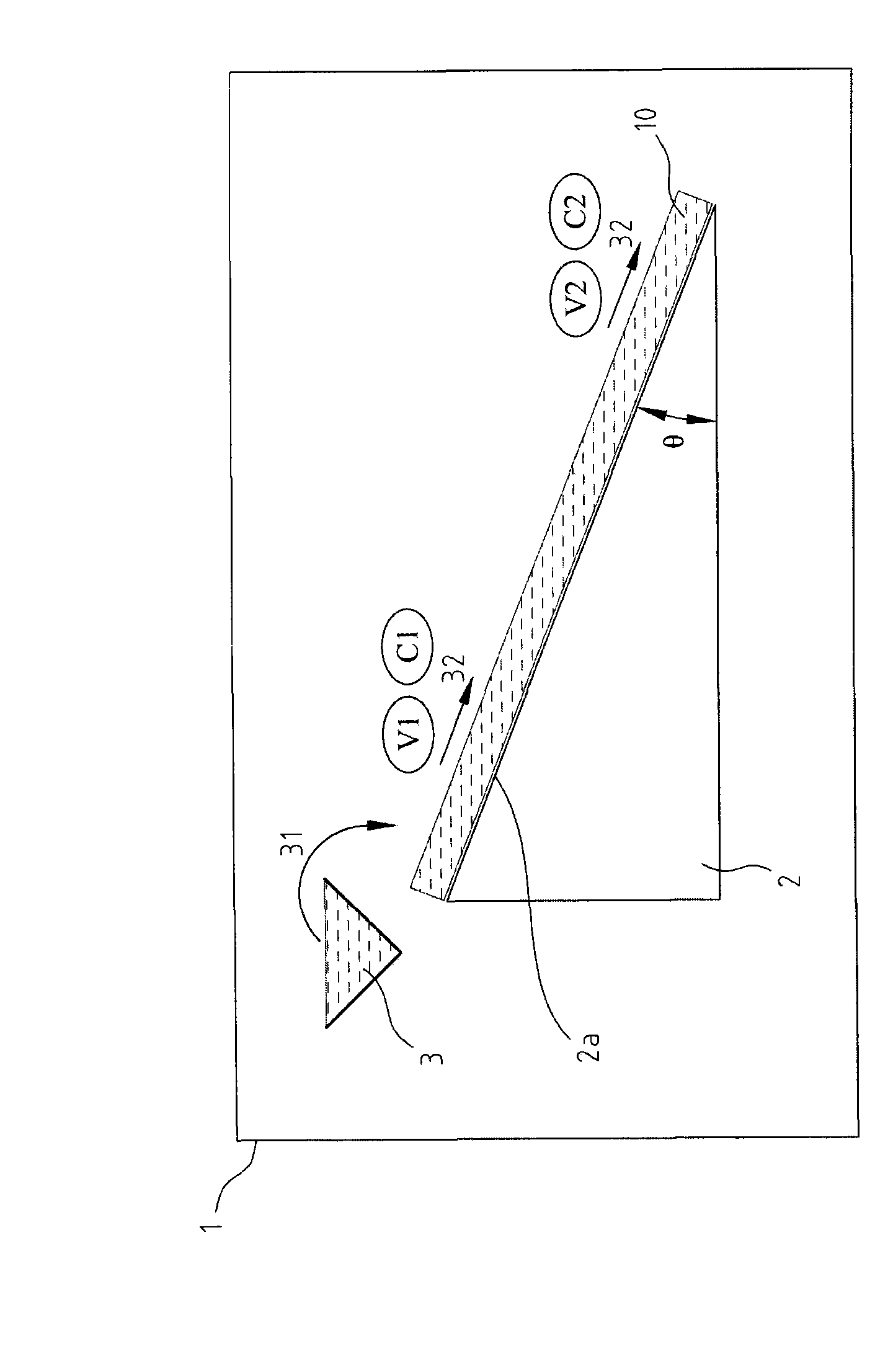

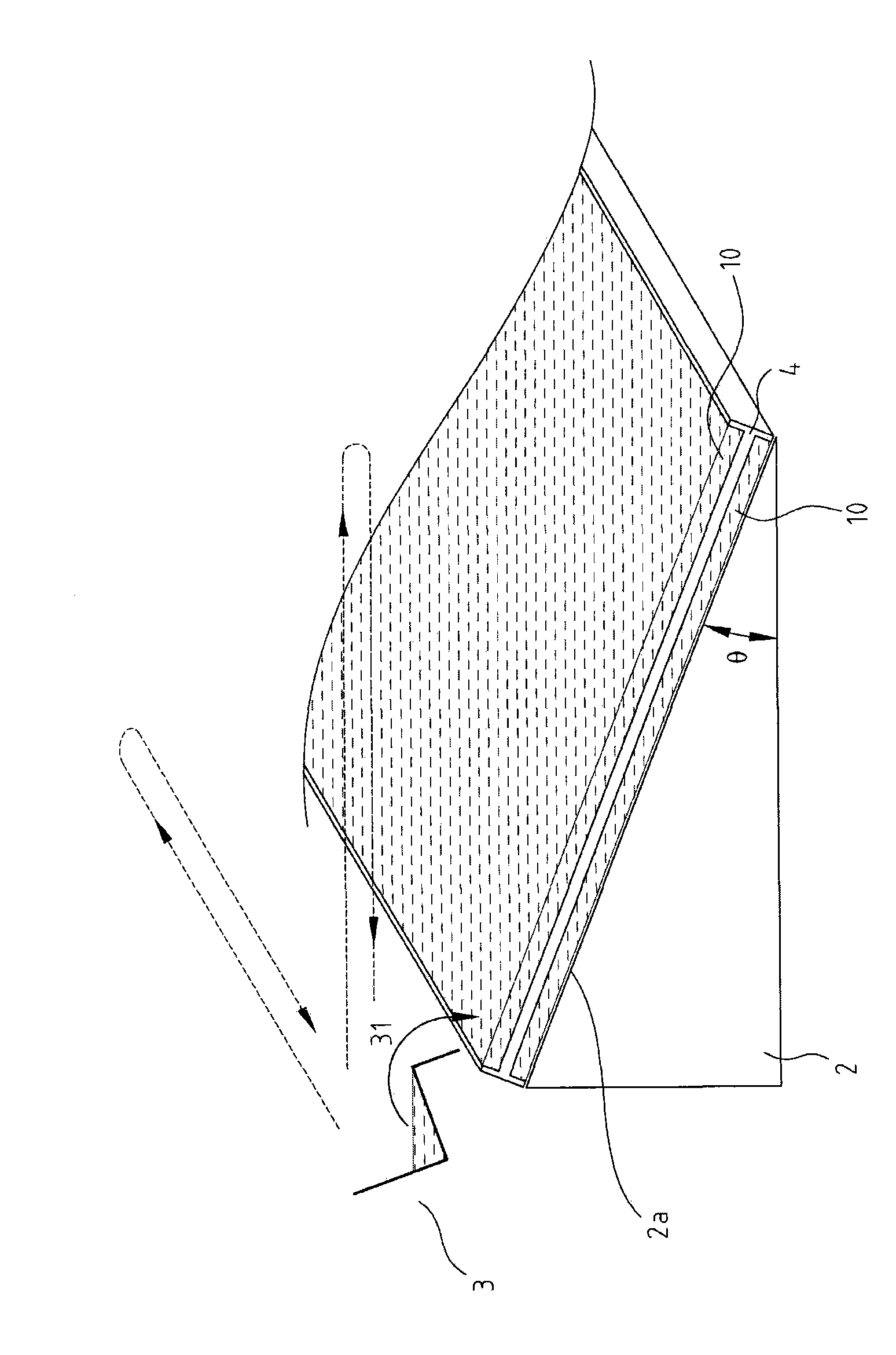

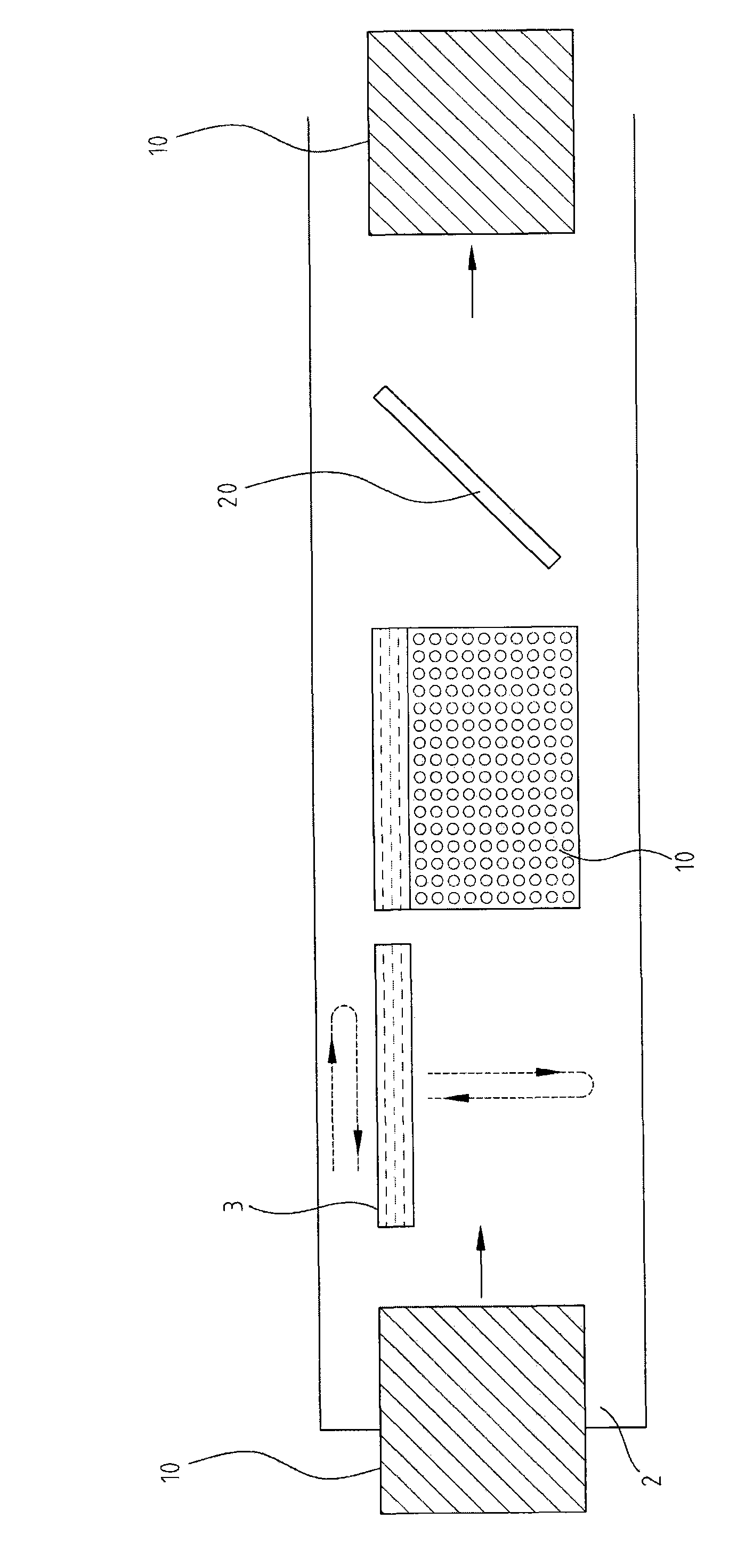

[0033] figure 1It is a schematic diagram for illustrating the situation of using the optical glass etching device of the present invention to perform the optical glass etching method. Such as figure 1 As shown in , the optical glass etching device 1 of the present invention mainly includes a stage 2 and a scanning waterfall overflow etching sprinkler 3 .

[0034] When utilizing the optical glass etching device 1 of the present invention to carry out the optical glass etching method, at first, utilize the inclined transmission stage to place the optical glass 10 on the inclined surface 2a of the stage 2 in an inclined manner, so that the optical glass 10 and the carrier The angle between the horizontal planes of platform 2 is between 0 degrees and 90 degrees; then, using the scanning waterfall overflow etching sprinkler 3, adopt the scanning waterfall overflow acid coating type, from the front, back and above the optical glass 10 / Or the way of scanning back and forth left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com