Compound air duct and method thereof

A composite air duct and air duct technology, applied in the direction of pipes, rigid pipes, heating methods, etc., can solve the problems of easy delamination, easy damage to the insulation layer, and can not be installed outdoors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

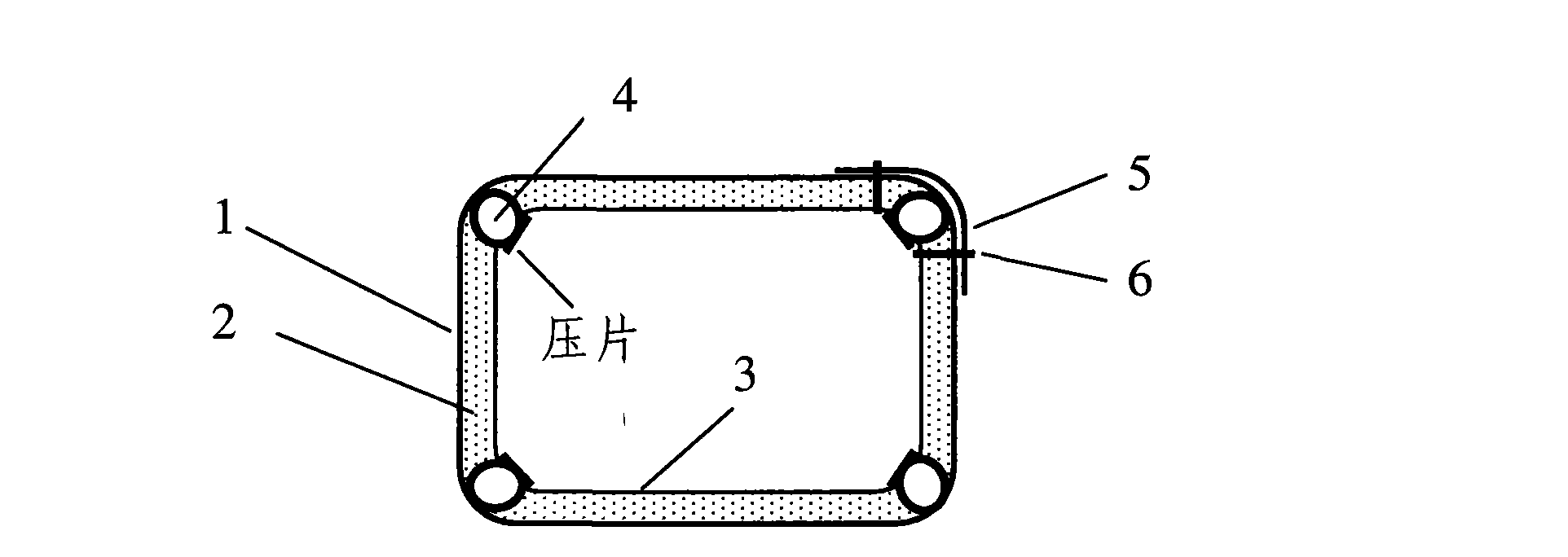

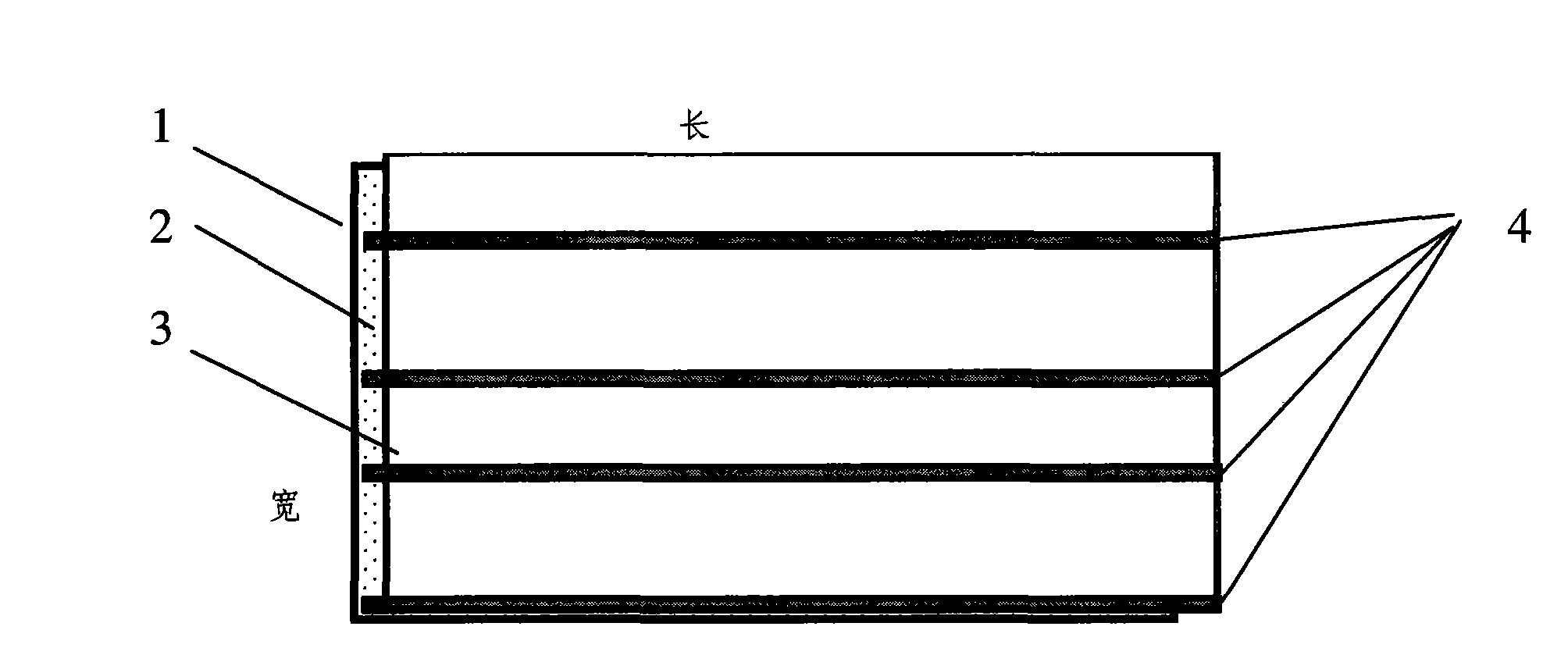

[0023] as attached figure 1 Shown is the structural schematic diagram of the cross-section of the composite air duct. Among them, 1 is the outer layer of the air duct, 2 is the insulation layer, 3 is the surface layer of the inner wall of the air duct, 4 is the hard pipe material, and 5 is the seam strip.

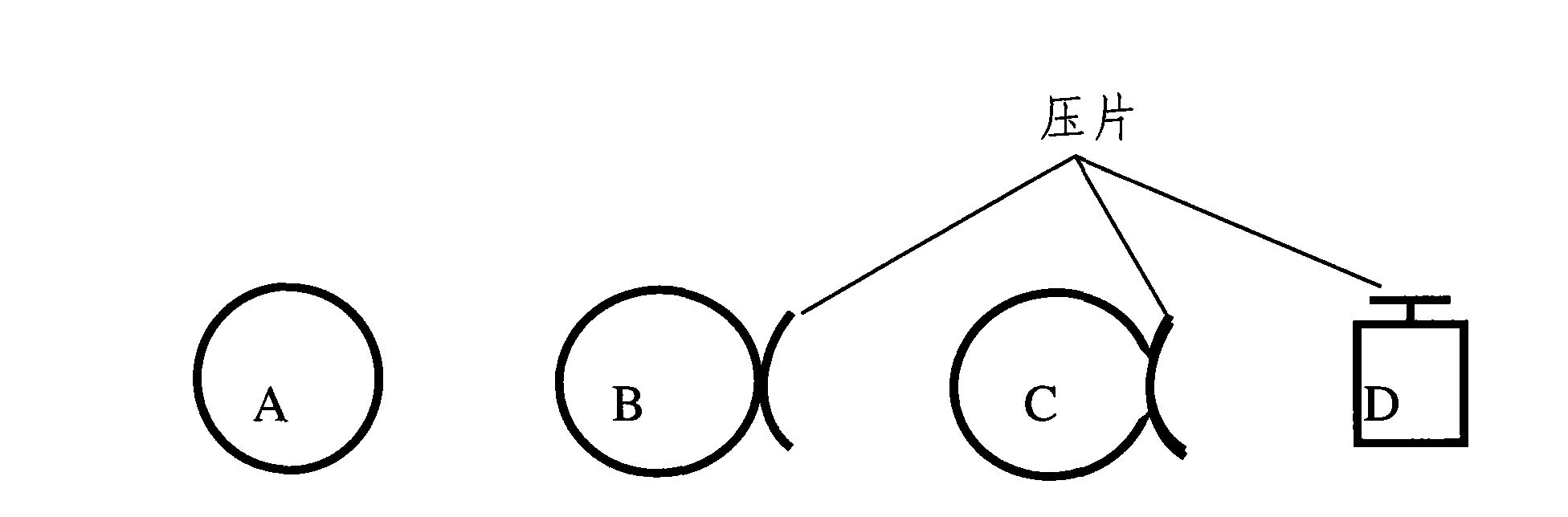

[0024] The manufacturing steps of the composite air duct include: calculating the position of the required corner according to the size of the air duct, pre-embedding the pipe material 4 between the outer layer 1 and the inner wall surface layer 3; bonding the prefabricated thermal insulation material between the outer layer 1 and the inner wall surface layer 3, Become the insulation layer 2 of the composite air duct; press and bond to make the air duct composite sheet containing the hard pipe (4); when the air duct is processed, the composite sheet is bent into 90 degrees around the pipe 4 toward the direction of the inner wall surface 3; Corresponding seam strips 5 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com