Integrated high-frequency electrodeless lamp

An electrodeless lamp, high-frequency technology, applied in the use of gas discharge lamps, parts of gas discharge lamps, discharge lamps, etc., can solve the problems of increasing the cost of high-frequency electrodeless lamps, occupying space, and poor heat dissipation. Achieve excellent heat dissipation effect, beautiful appearance and effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

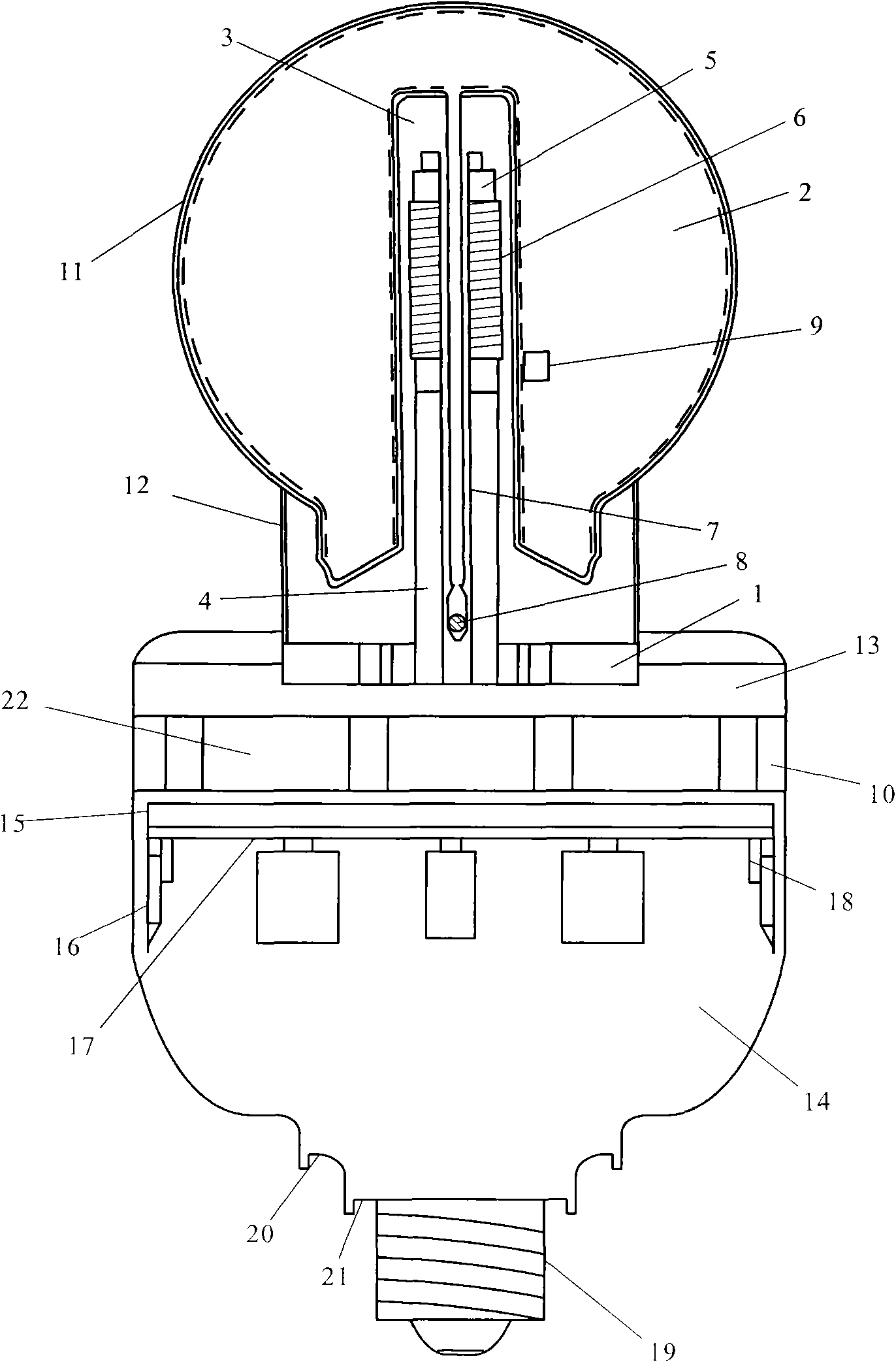

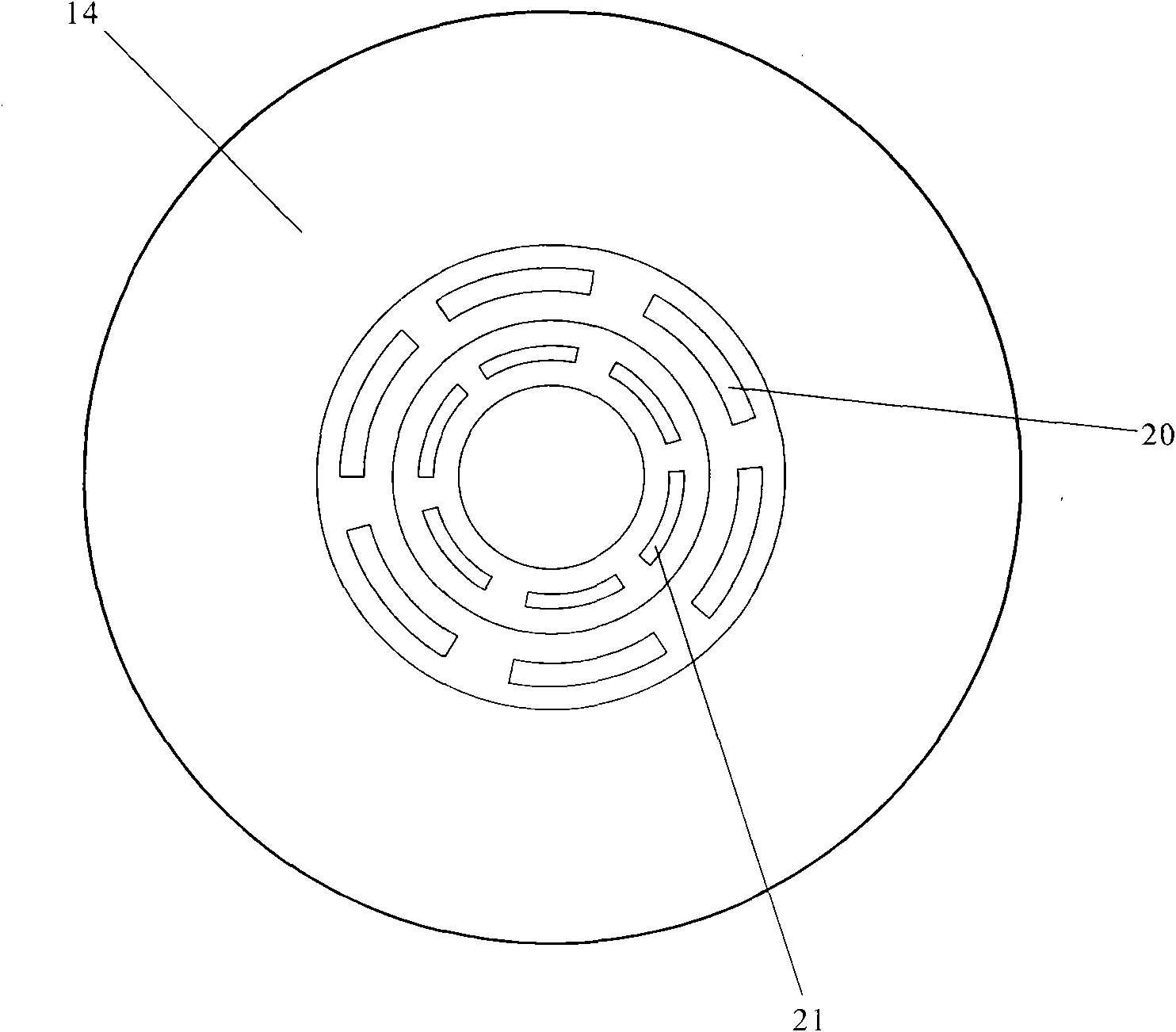

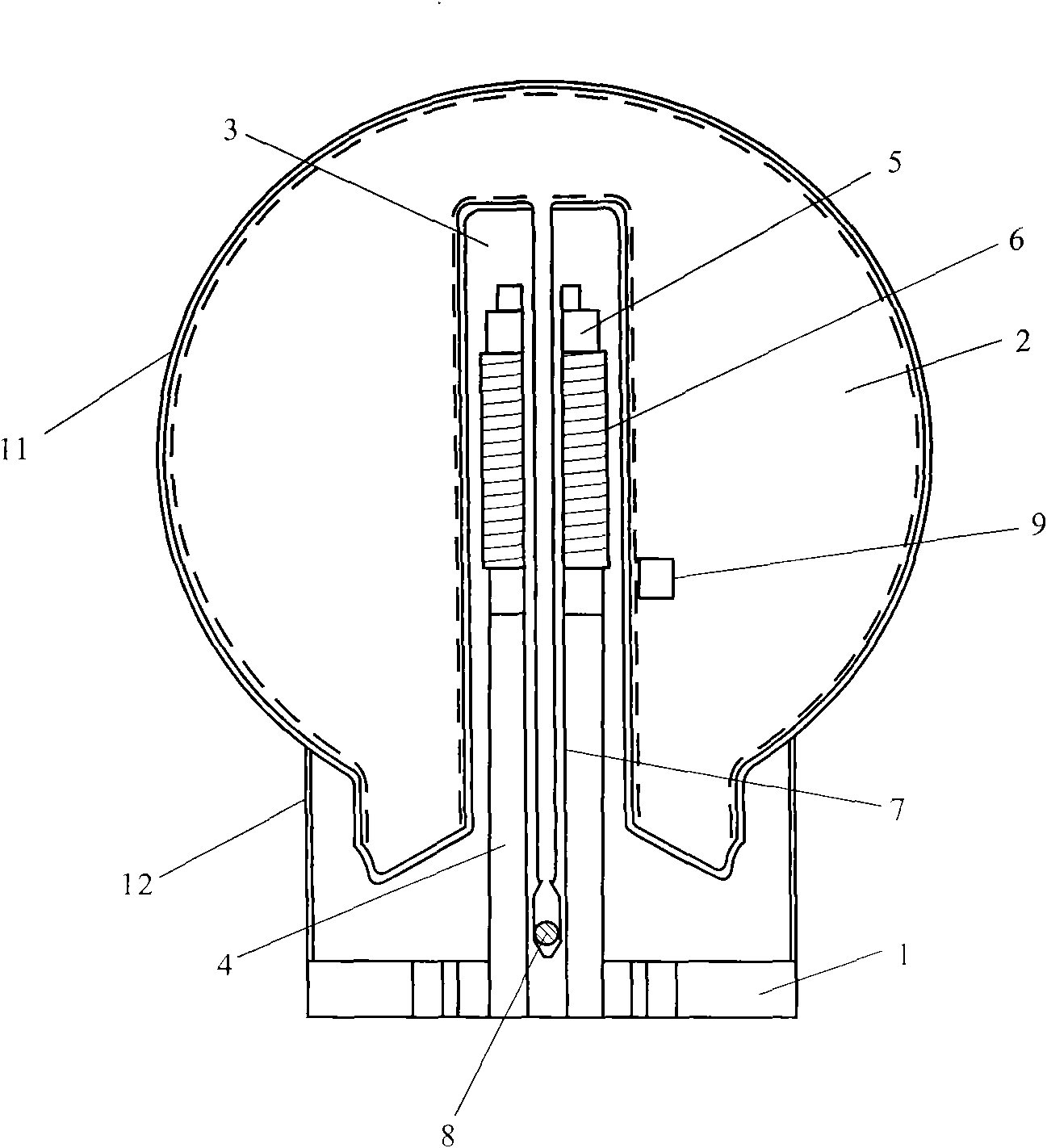

[0018] Please refer to Figure 1 to Figure 3 , figure 1 It is a cross-sectional view of the integrated high-frequency electrodeless lamp of the present invention, figure 2 is a top view of the present invention, image 3 It is a cross-sectional view of the high-frequency electrodeless lamp of the present invention. As shown in the figure, the integrated high-frequency electrodeless lamp has a high-frequency generator as a head and a high-frequency electrodeless bulb mounted on the high-frequency generator, wherein the high-frequency generator further includes a high-frequency generator for installing The lower shell 13, the middle heat insulation seat 10, the upper shell 14 and the lamp holder 19 installed on the upper shell 14 for connecting an external power source of the high frequency induction lamp, the middle heat insulation seat 10 and the upper shell 14 form a space that can accommodate In the cavity of the power cooling base 15, the circuit module 17 of the high f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com