Elastic jack contact

A technology of elastic jacks and contacts, which is applied in the direction of contact parts, fixed/insulated contact components, etc., can solve the problems of small current carrying capacity, large insertion and withdrawal force, and does not support live plugging and unplugging, etc. The effect of low force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

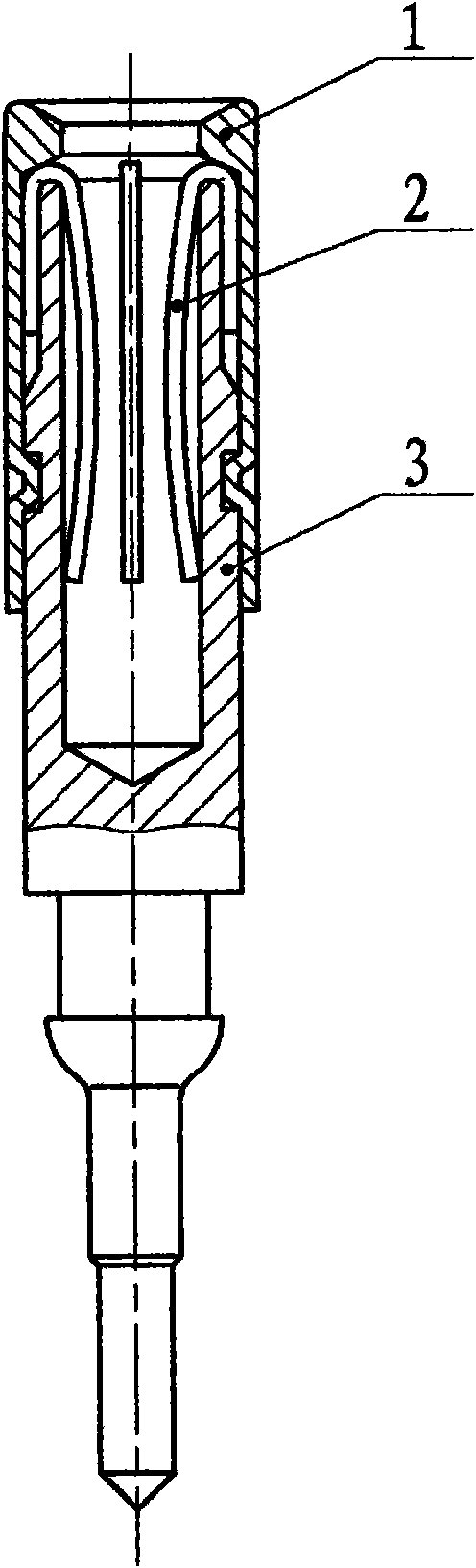

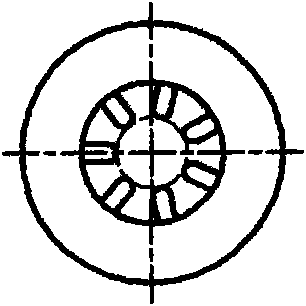

[0014] The elastic socket contact piece of the present invention is composed of a sheath 1, an elastic piece 2 and a socket 3. The elastic piece 2 is the core part of the elastic socket contact piece. The arc-shaped contact part and the elastic spring wire of the hook-shaped fixed part are fixed on the end face of the socket 3 to form a fixed fulcrum, and the arc-shaped contact part is a cantilever to form a sliding fulcrum. Each spring wire is Form a standard simply supported beam mechanics model.

[0015] In order to obtain higher rigidity, the diameter of the spring wire is thicker than that of the common wire spring socket with both ends fixed. In addition, in order to obtain higher hardness and elasticity, the spring wire is heat-treated after bending and forming, and the final part is formed after being gold-plated. In the hole of the jack 3, a plurality of spring wires are evenly distributed on the circumference. After the spring wires are assembled in place, the sheat...

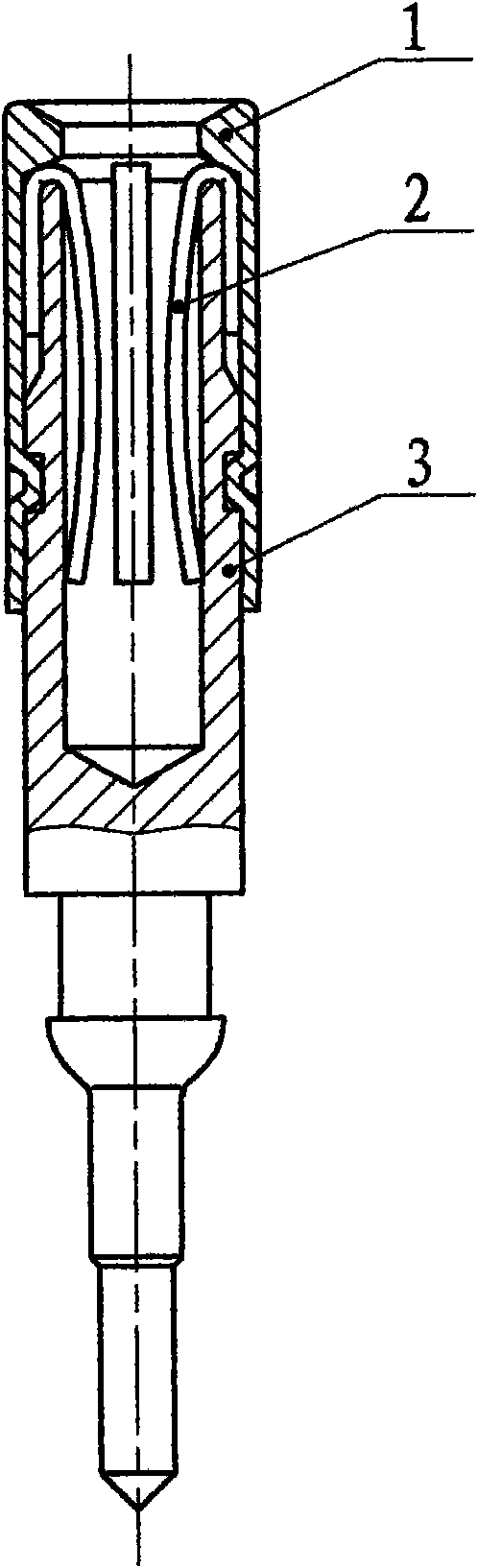

Embodiment 2

[0018] The elastic socket contact piece of the present invention is composed of a sheath 1, an elastic piece 2 and a socket 3. The elastic piece 2 is the core part of the socket contact piece. The elastic reed with the contact part in the shape of a hook and the fixed part in the shape of a hook, the fixed part is fixed on the end face of the socket 3 to form a fixed fulcrum, and the arc-shaped contact part is a cantilever to form a sliding fulcrum. The standard simply supported beam mechanical model, also in order to obtain higher hardness and elasticity, the reed is heat treated after bending and forming, and the final part is formed after gold plating. In the hole of the jack 3, a plurality of reeds are evenly distributed on the circumference. After the reeds are assembled in place, the sheath 1 is assembled. The sheath 1, the reeds and the jack 3 adopt interference fit, and the sheath 1 is assembled in place. , that is, the reed is fixed in the jack 3, and the contact part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com